7-14

Component Access / Removal

Built-In

Built-In

(600-

(600-

2

2

)

)

Series

Series

#3758407 - Revision B - August, 2006

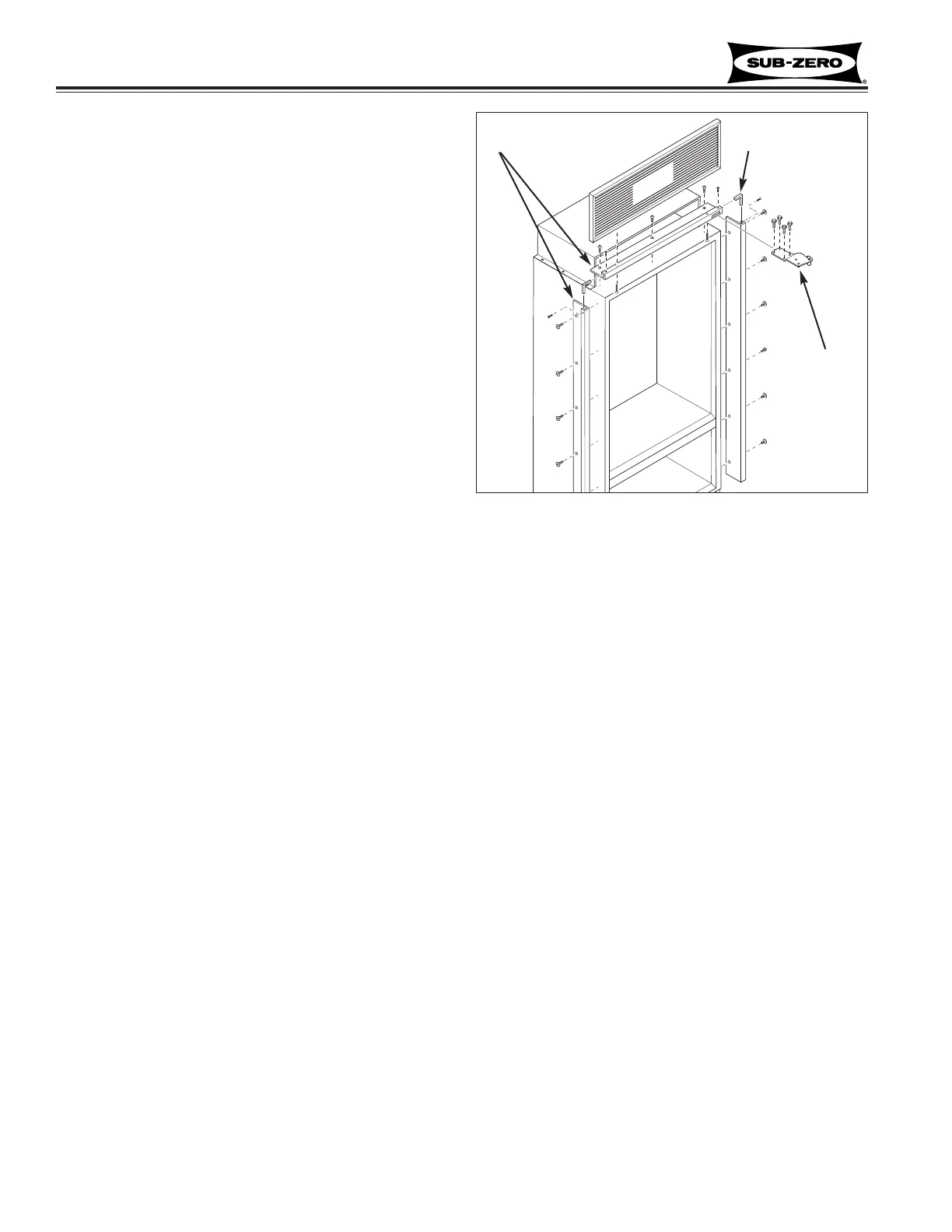

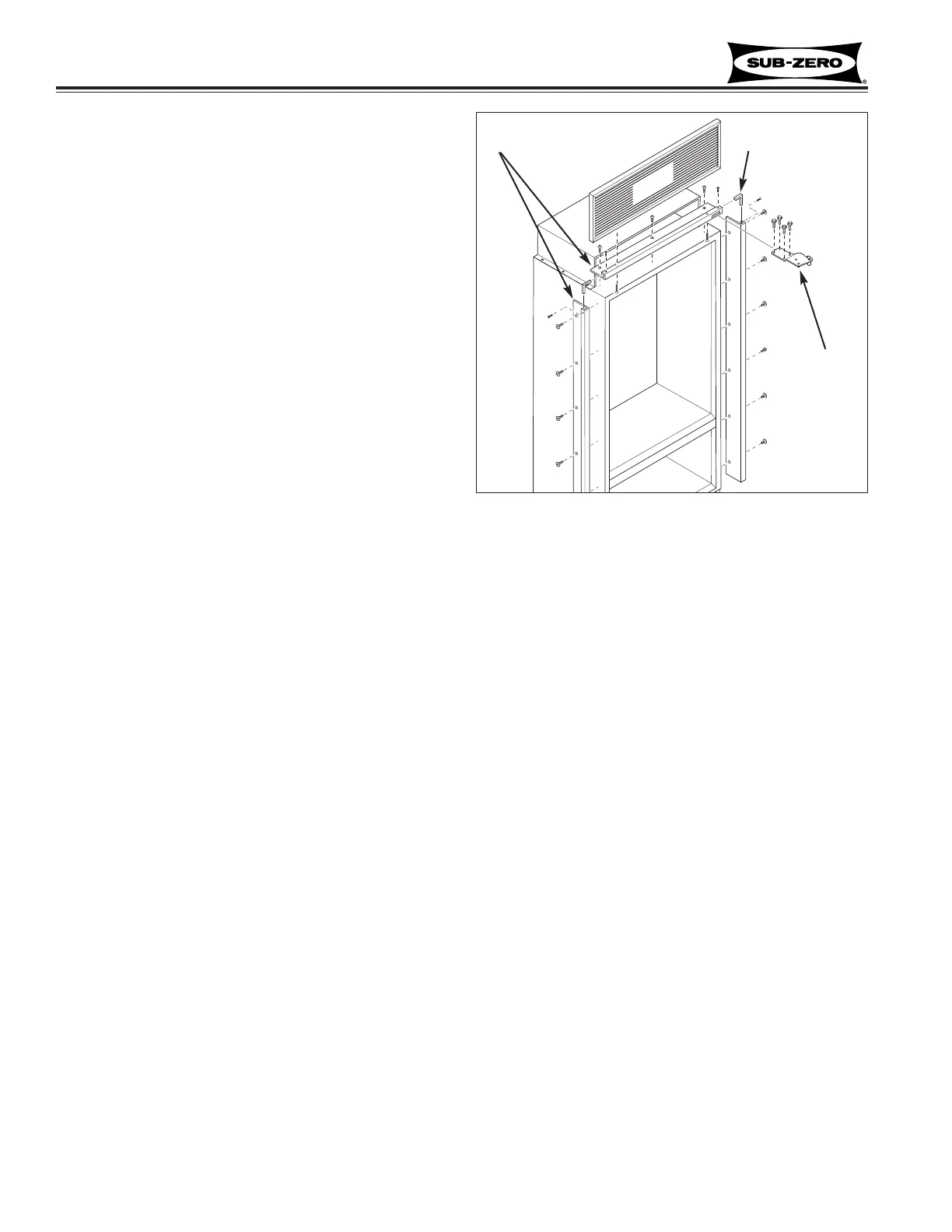

Mainframe Extrusion (All Models)

Mainframe extrusion is held to the sides of a unit with

low-profile 6-lobe drive screws, and at the top with

Phillips-head screws. Mainframe angles at the top cor-

ners strengthen and support mainframes at a 90° angle.

Side Mainframe Extrusion, (See Figure 7-31):

1. Pull unit from its installation approximately 4”.

2. Remove grille.

3. Remove aluminum tape from top corner.

4. Remove nut from bottom hinge stud (if applicable).

5. With a T-20 6-lobe bit, extract mounting screws.

6. With a small Phillips-head bit, extract screw at top

of mainframe angle and pull extrusion from unit.

Top Mainframe Extrusion, (See Figure 7-31):

1. Pull unit from its installation approximately 4”.

2. Remove grille.

3. Remove aluminum tape from corners.

4. Remove door(s) and top cabinet hinge(s).

5. With a Phillips-head bit, extract mounting screws.

6. With small Phillips-head bit, extract screws at side

of mainframe angles and pull extrusion from unit.

Figure 7-31. Mainframe Extrusion

Grille

Cabinet

Hinge

Mainframe Angle

Mainframe

Loading...

Loading...