4-4

Sealed System Information

7011902 - Revision A - October, 2009

International Integrated

International Integrated

(ICB700 Base)

(ICB700 Base)

Series

Series

SEALED SYSTEM

OPERATION

The six diagrams on these

pages illustrate a basic sealed

system. The components are

listed in order of refrigerant

flow, with an explanation of

their fundamental role as part

of a sealed system.

NOTE: These illustrations rep-

resent an ICB700BCI sealed

system.

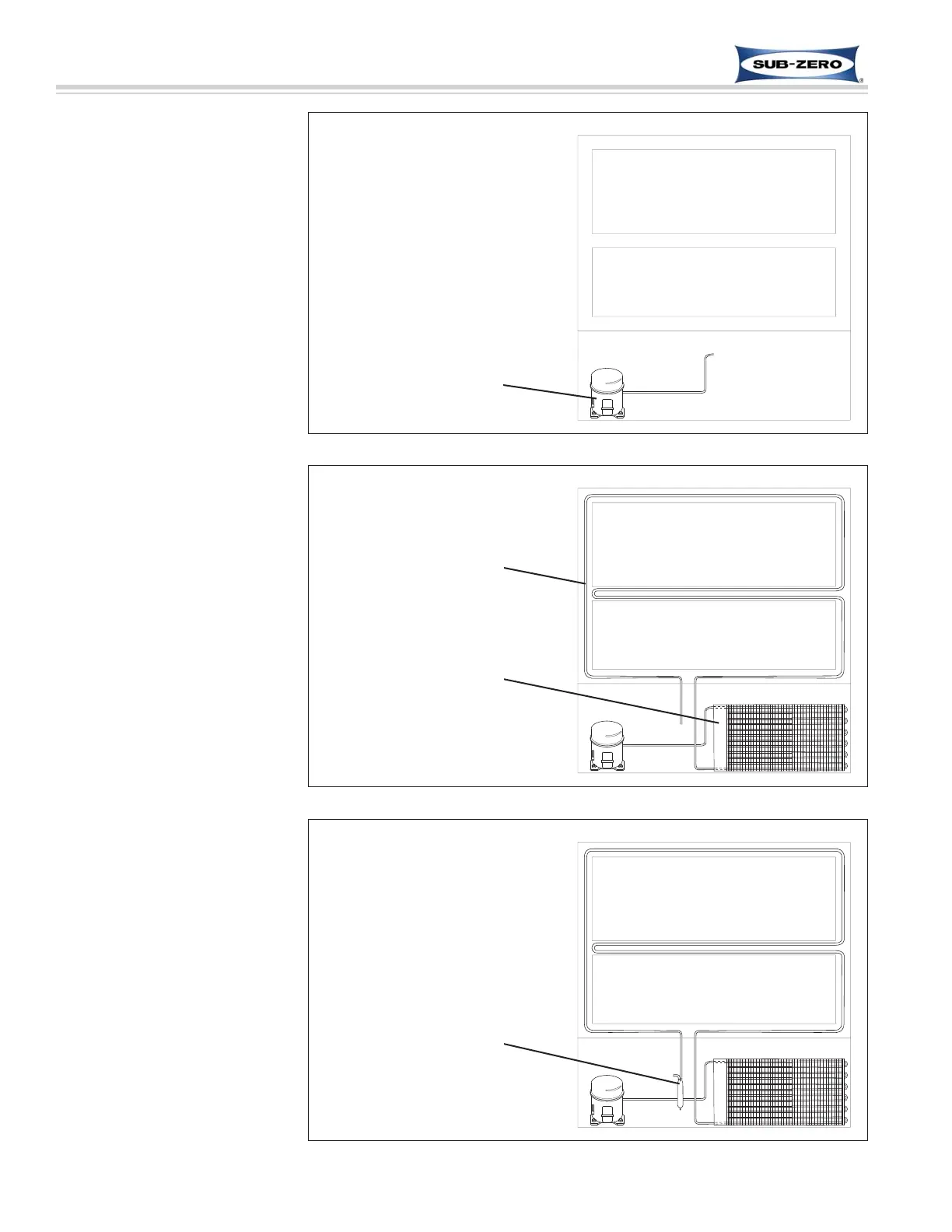

Compressor (Figure 4-1)

The compressor creates a high

side and low side pressure dif-

ference in the sealed system

by compressing the refrigerant

gas, thus raising the pressure

and temperature. The com-

pressor pushes this high-pres-

sure/high-heat gas to the con-

denser.

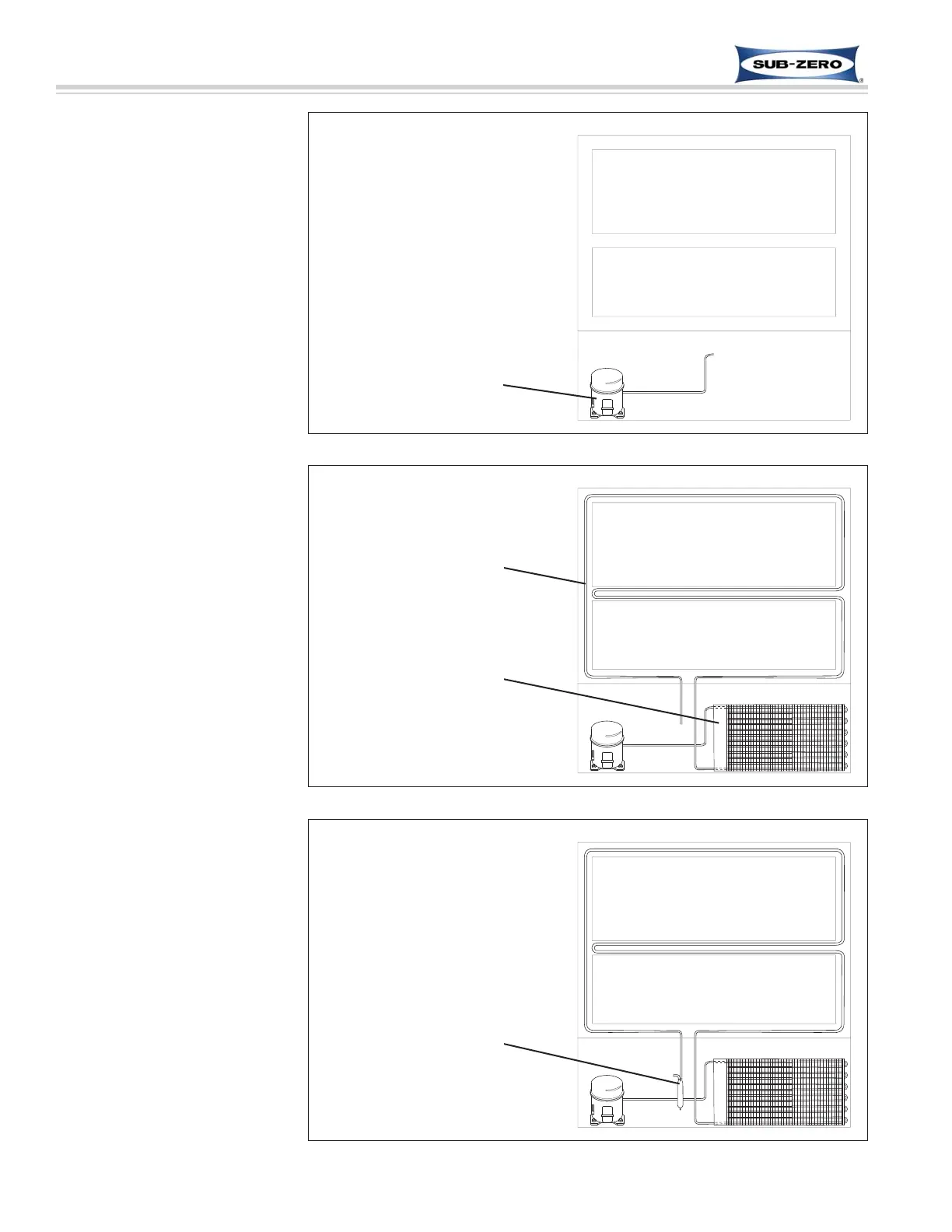

Condenser (Figure 4-2)

The high-pressure/high-heat

gas travels through the con-

denser, where the heat is dissi-

pated by cooler air being drawn

over the condenser tubing by

the condenser fan. This

changes the gas into a high-

pressure/warm liquid that is

then routed through the door

gasket seat heater loop to pre-

vent sweating. After traveling

through the heater loop, the

high-pressure/warm liquid

enters the high-side filter-drier.

Filter-Drier (Figure 4-3)

The high-pressure/warm liquid

travels through the high-side fil-

ter-drier, which removes mois-

ture from the refrigerant before

it enters the capillary tube.

Figure 4-1. Compressor

Figure 4-3. Filter-Drier

Figure 4-2. Condenser & Heater Loop

COMPRESSOR

CONDENSER

HEATER LOOP

FILTER-DRIER

Loading...

Loading...