7-21

Component Access/Removal

7011902 - Revision A - October, 2009

International Integrated

International Integrated

(ICB700 Base)

(ICB700 Base)

Series

Series

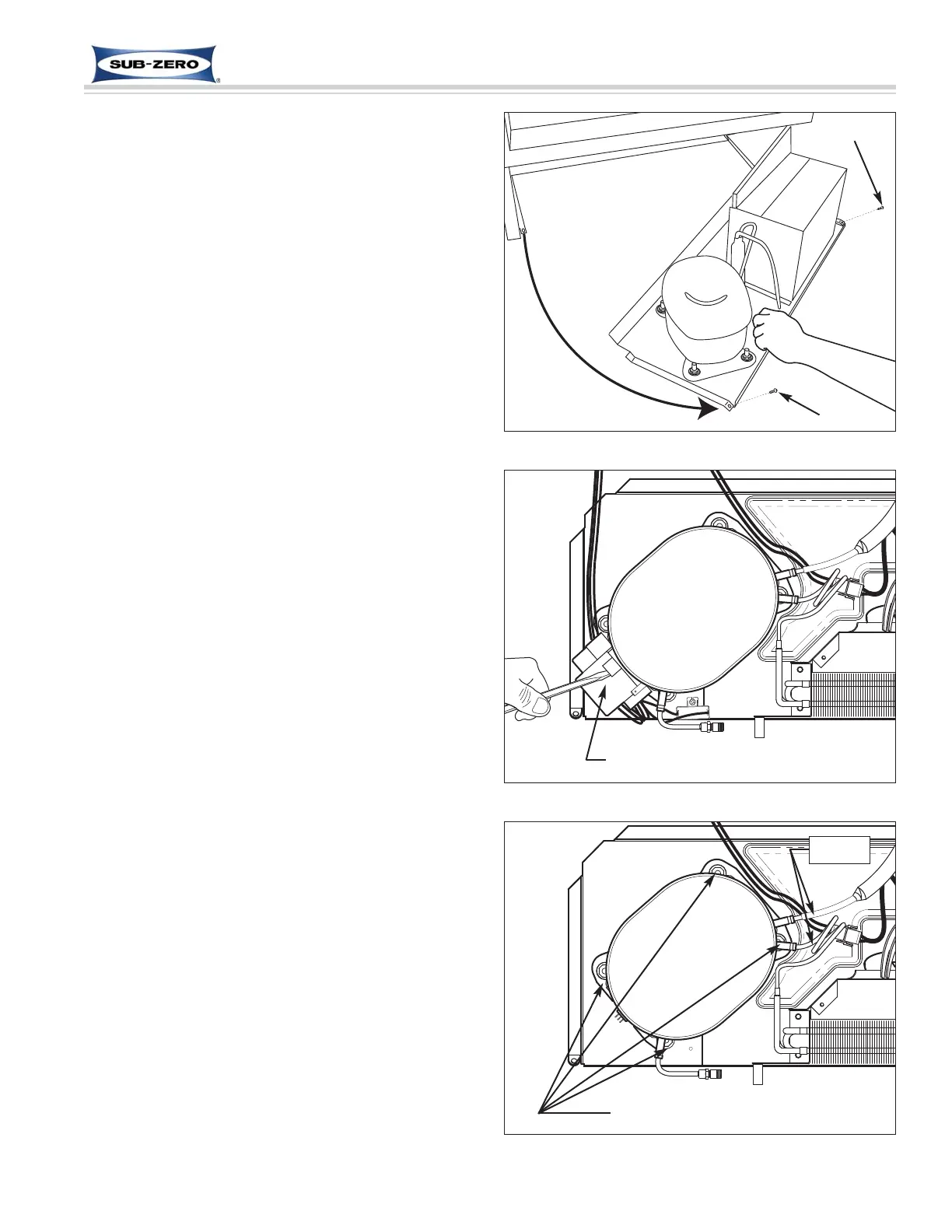

Figure 7-46. Sliding Unit Tray Out

Screw

Screw

Compressor Removal (All Base Units)

The compressor has four rubber compressor grommets

inserted into its base. Cylindrical metal spacers are

placed over threaded studs that are press fit to the unit

tray. The compressor grommets fit over the spacers

and a washer sets on top of the grommet and spacer.

A nut is then installed on the threaded stud and tight-

ened down on the washer and spacer.

NOTE: Before attempting to remove a compressor,

evacuate the refrigerant from the sealed system.

To remove the compressor, the kickplate/grill will need

to be removed first. Then, extract the two screws that

secure the unit tray to the unit and slide the tray out

(See Figure 7-46), then (See Figures 7-48 and 7-48).

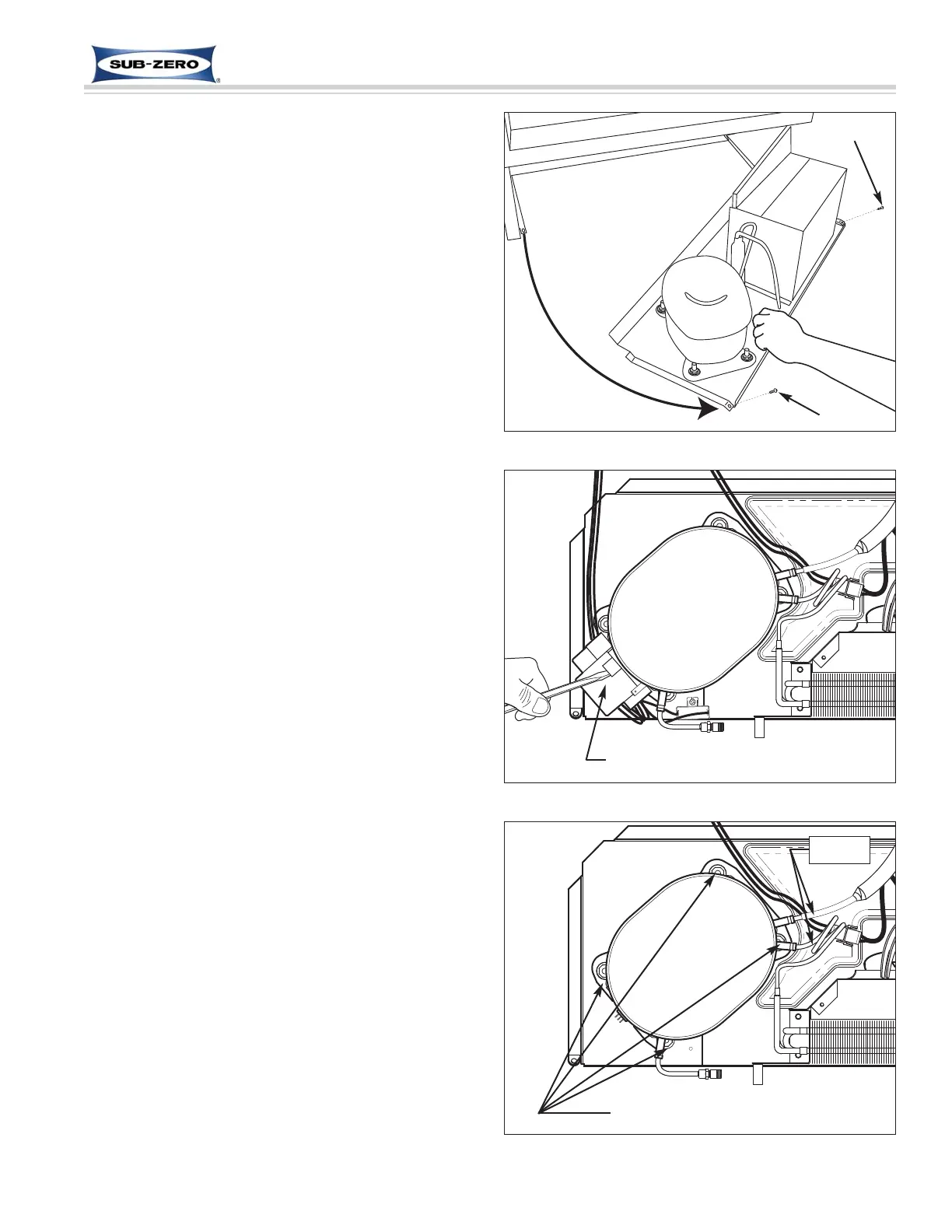

1. Use a flat-blade screwdriver to remove compressor

electrical cover

2. Disconnect electrical leads from compressor.

3. Cut compressor inlet and outlet tubing with a tube

cutter, approximately 25 mm (1'') from compressor

ports.

4. Extract nuts and washers from threaded studs.

5. Lift compressor off of threaded studs.

NOTE: Sweating the joints apart is not recommended

as this may induce moisture into the sealed system.

NOTE: The high-side filter-drier must be replaced

whenever servicing the sealed system.

NOTE: When installing a compressor, be sure to thor-

oughly clean the tubing before brazing.

Figure 7-47. Removing Compressor Electrical Cap

Figure 7-48. Compressor Removal

Pry up with screwdriver

Cut here

Compressor

Compressor

Remove nuts and washers

Loading...

Loading...