7-20

Component Access/Removal

7011902 - Revision A - October, 2009

International Integrated

International Integrated

(ICB700 Base)

(ICB700 Base)

Series

Series

SEALED SYSTEM COMPONENTS

NOTE: When entering the sealed system, always use

solder-on process valves. Do NOT use bolt-on process

valves as they are prone to leak.

NOTE: Whenever servicing the sealed system, the

high-side filter-drier must

be replaced.

High-Side Filter-Drier Removal (All Base Units)

The high-side filter-drier is located to the right of the

condenser and is attached to the condenser outlet tube

with a cable tie.

NOTE: Before attempting to remove a filter drier, evac-

uate refrigerant from sealed system.

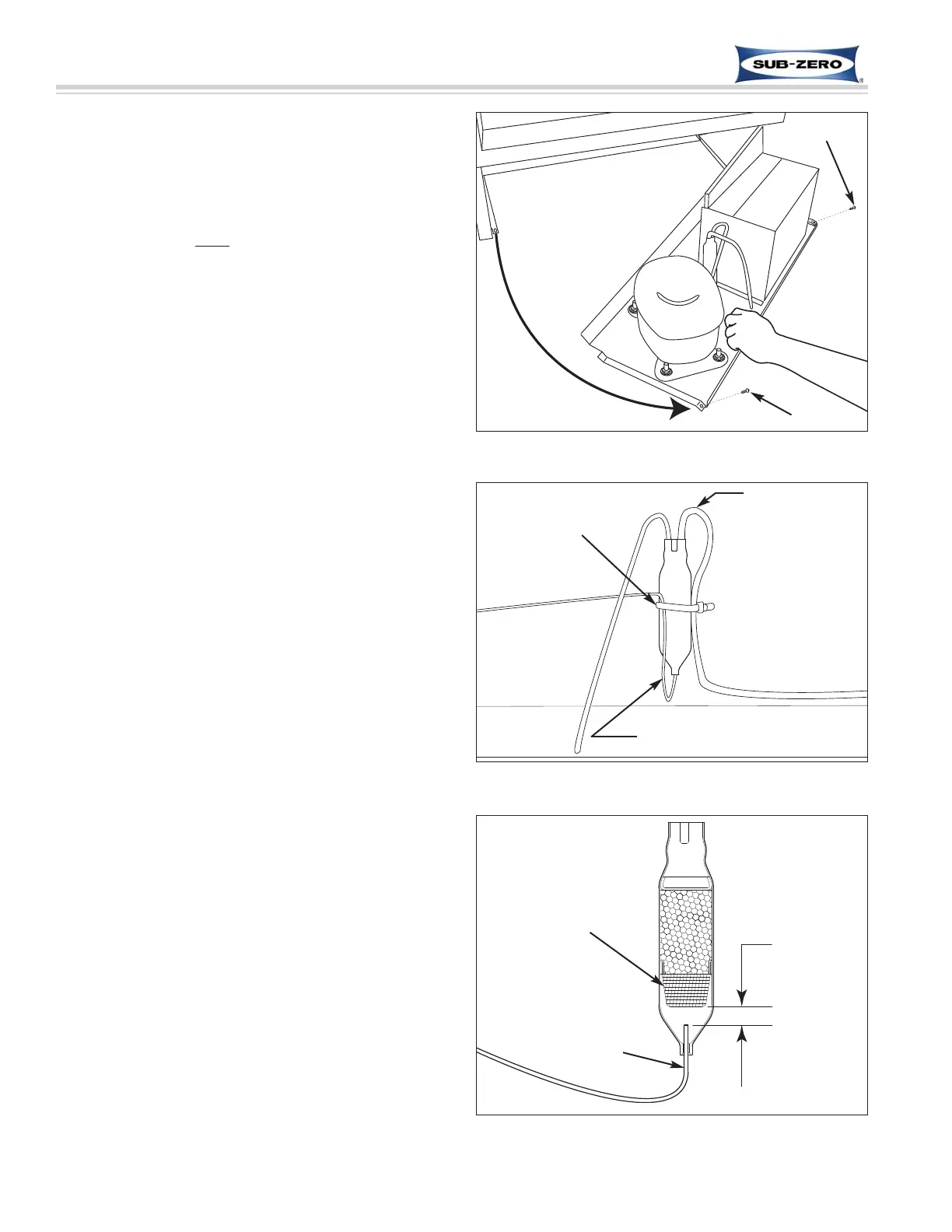

To remove the filter-drier, the kickplate/grill will need to

be removed first. Then, extract the two screws that

secure the unit tray to the unit and slide the tray out

(See Figure 7-43).

NOTE: It may be necessary to disconnect the com-

pressor electrical leads in order to pull the tray out far

enough to access the filter-driers.

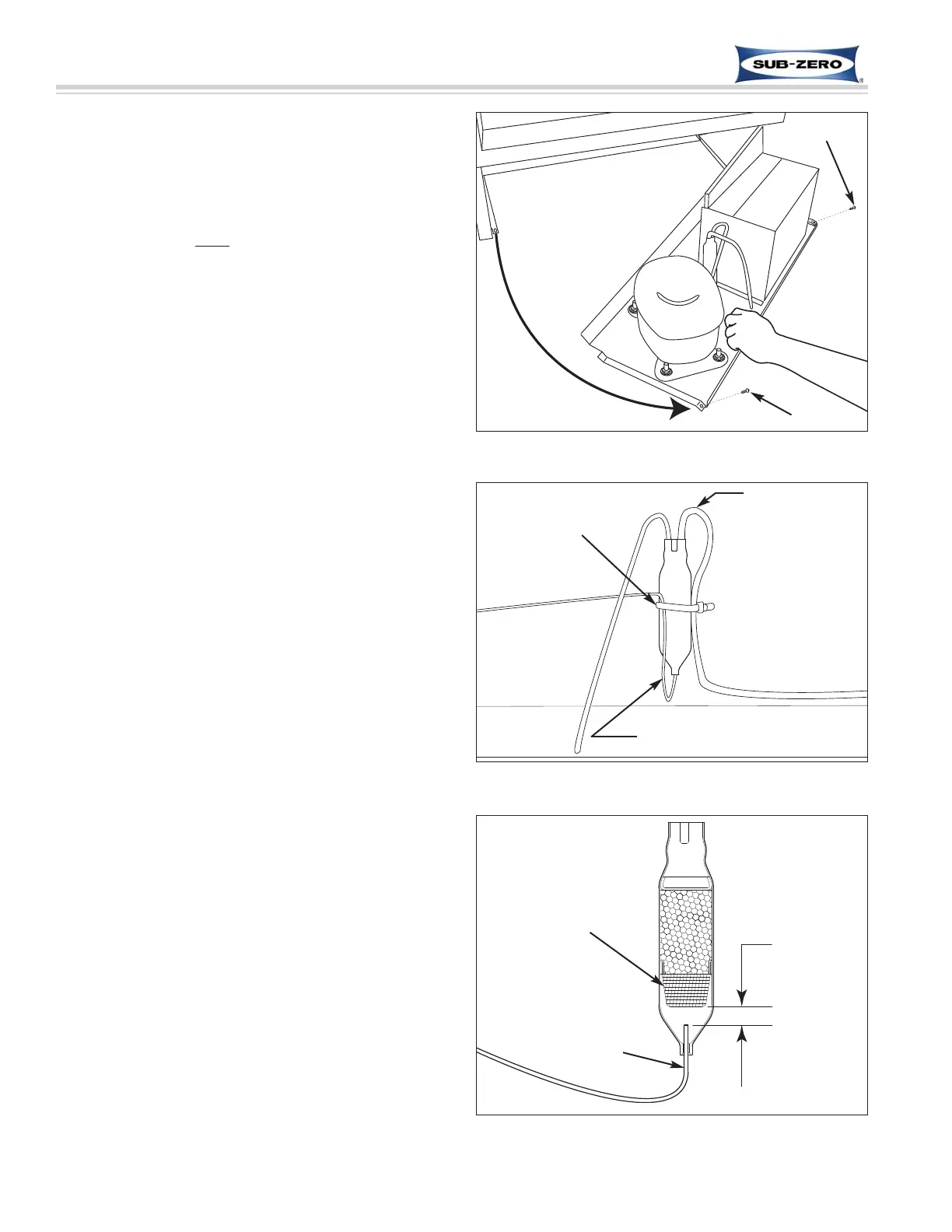

To Remove the filter drier (See Figure 7-44):

1. Cut cable tie securing filter-drier to bracket, or con-

denser outlet tube.

2. With the edge of a file, score a line around capillary

tube approximately 25 mm (1'') from filter-drier

outlet.

3. Fatigue capillary tube at line just scored until it sep-

arates.

4. With a tube cutter, cut inlet tube approximately one

inch 25 mm (1'') from filter-drier.

NOTE: Sweating the joints apart is not recommended

as this may induce moisture into the sealed system and

could cause a solder restriction in the capillary tube.

NOTE: Check the end of the remaining capillary tube

for internal burrs. If burrs exist, rescore a line around

the capillary tube approximately one inch from the end

and fatigue the capillary tube at this new line until it

separates.

NOTE: When installing the replacement filter-drier,

insert the capillary tube until it touches the screen, then

pull the capillary tube approximately 9.5 mm (3/8”)

away from the screen before brazing (See Figure 7-45).

When installing a new filter-drier, be sure to thoroughly

clean the tubing before brazing.

Figure 7-43. Sliding Unit Tray Out

Figure 7-44. Filter-Drier Removal

Loading...

Loading...