SERVICE BULLETIN NO. 18

INSTRUCTIONS FOR SERVICING SUNBEAM MIXMASTER

MODEL 3 AUTOMATIC

(See Model Number Stamped on Bottom of Mixmaster Base)

Revised May 14, 1949

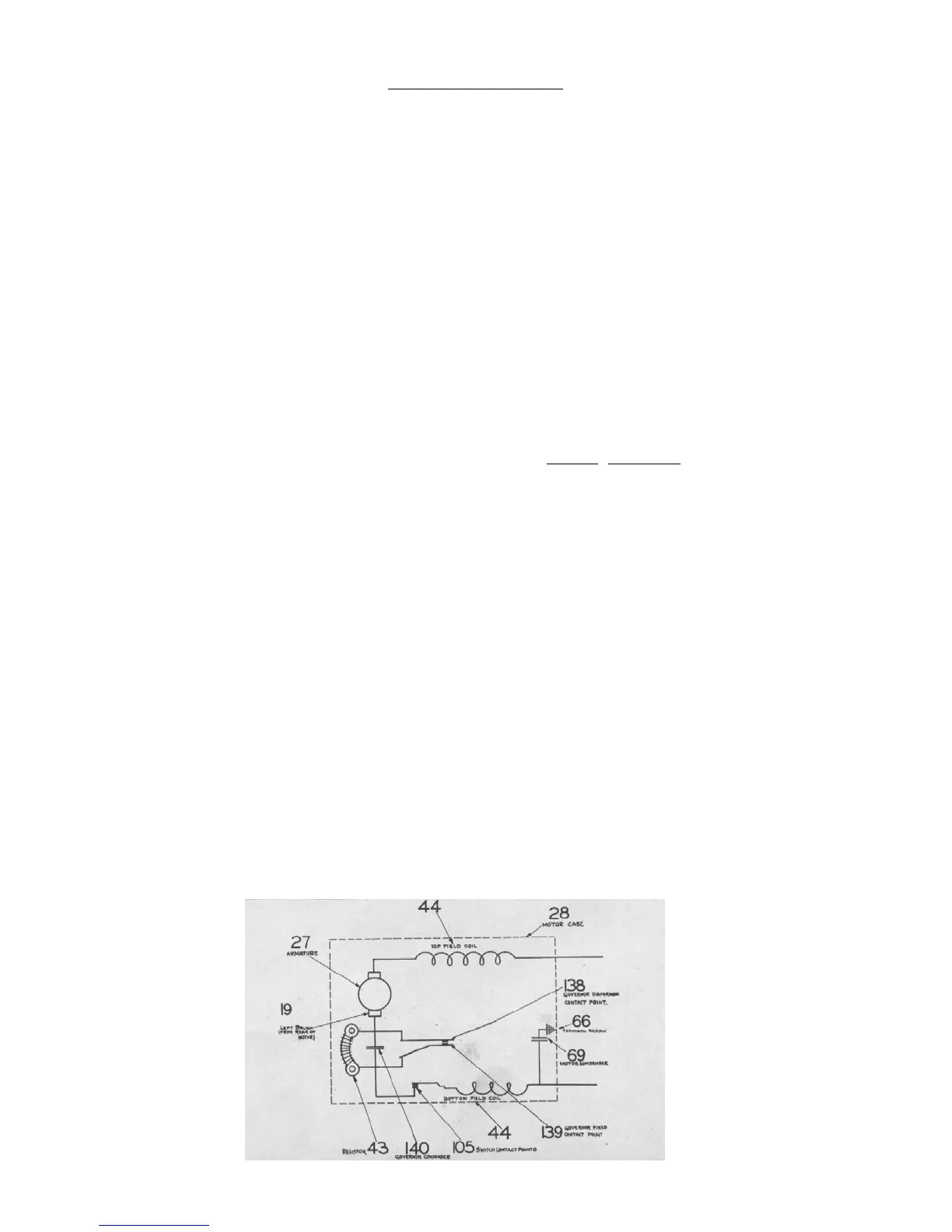

The Model 3 Automatic Mixmaster motor is controlled by an air governor that

operates on the following principle: A fan draws air into the motor housing

through the grille on the front, carries it past the armature and field coils, on

through the governor control, and delivers it out the back of the motor. Between

the fan and the air vent is a Bakelite disc that closes the back or the motor

housing. In the center or the disc a rectangular opening is placed, then across

the opening a thin blue steel shutter plate, or diaphragm is fitted with one edge

fixed to the Bakelite disc. A contact breaker point is riveted on the diaphragm.

Directly opposite another breaker point is attached to an arm.

As the air is pulled through the motor it pushes back the diaphragm to provide an

opening for the air to flow through and this action breaks the current flow

through the governor contact points. The amount or air pressure required to open

the diaphragm depends upon the resistance of the diaphragm to the air. To control

this resistance, tension is applied through the contact breaker point fitted on

an arm (this breaker point will be celled the Fixed

Contact throughout the

remainder of this bulletin, because the position of that contact point remains

fixed for any particular speed, its position being determined by the setting of

the switch knob).

When you turn the switch knob at the back of the motor you increase or decrease

the tension on the diaphragm by moving the arm slightly backward or forward. With

the switch knob turned to the lower speeds the tension against the diaphragm is

very light; the diaphragm opens easily, thereby breaking the current quickly. But

when the knob is turned to the higher speeds the arm applies more tension on the

diaphragm and a greater air pressure is required to open it and break the

current. Thus by adjusting the tension on the diaphragm and by alternately making

and breaking the current flow at a very rapid rate the governor maintains a

constant motor speed under all load and nominal voltage variations.

A condenser and resistor fitted on the Bakelite governor disc are shunted across

the governor breaker points to give the points long life and to reduce radio

interference. The resistor also smoothes out the operation of the motor by

allowing a small fraction of the current to flow through the motor while the

breaker points are open momentarily. A second filter condenser is fitted in the

lower part of the motor housing to reduce and eliminate radio interference.

Wiring Diagram Model 3 Automatic Mixmaster

Loading...

Loading...