,

D.

Welding introductio[l

1.Welding

pressure

adjuster

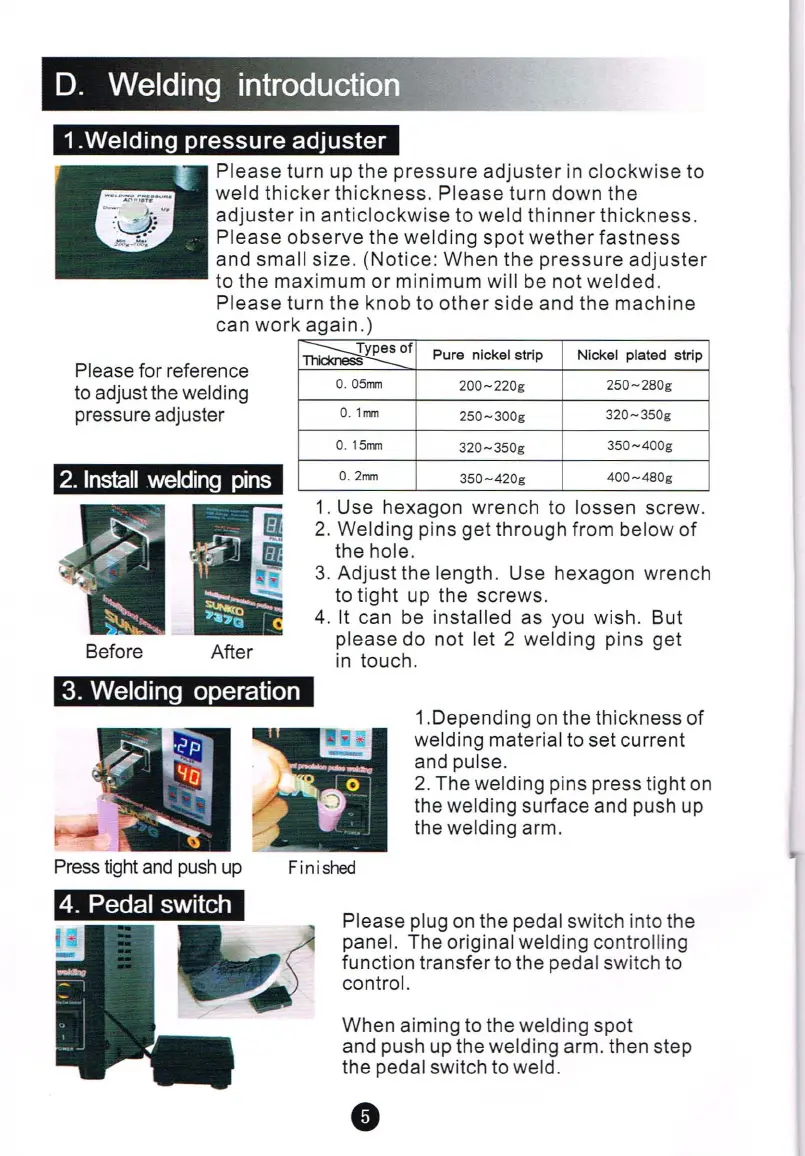

Please

turn up the

pressure

adjuster

in

clockwise

to

weld

thicker

thickness

.

Please

turn

down

the

adjuster

in

anticlockwise

to weld

thinner

thickness.

Please

observe

the

welding

spot

wether

fastness

and

small

size.

(Notice:

When the

pressure

adjuster

to

the

maximum

or

minimum will be

not

welded

.

Please

turn the knob to

other

side and the

machine

can

work

again.)

~ypesof

Pure nickel strip Nickel plated strip

Please for reference

to adjust the welding

pressure adjuster

Thid<ness--..<..!.......

O.

05mm

O.

1rrrn

200-220g

250-280g

250-300g

320-350g

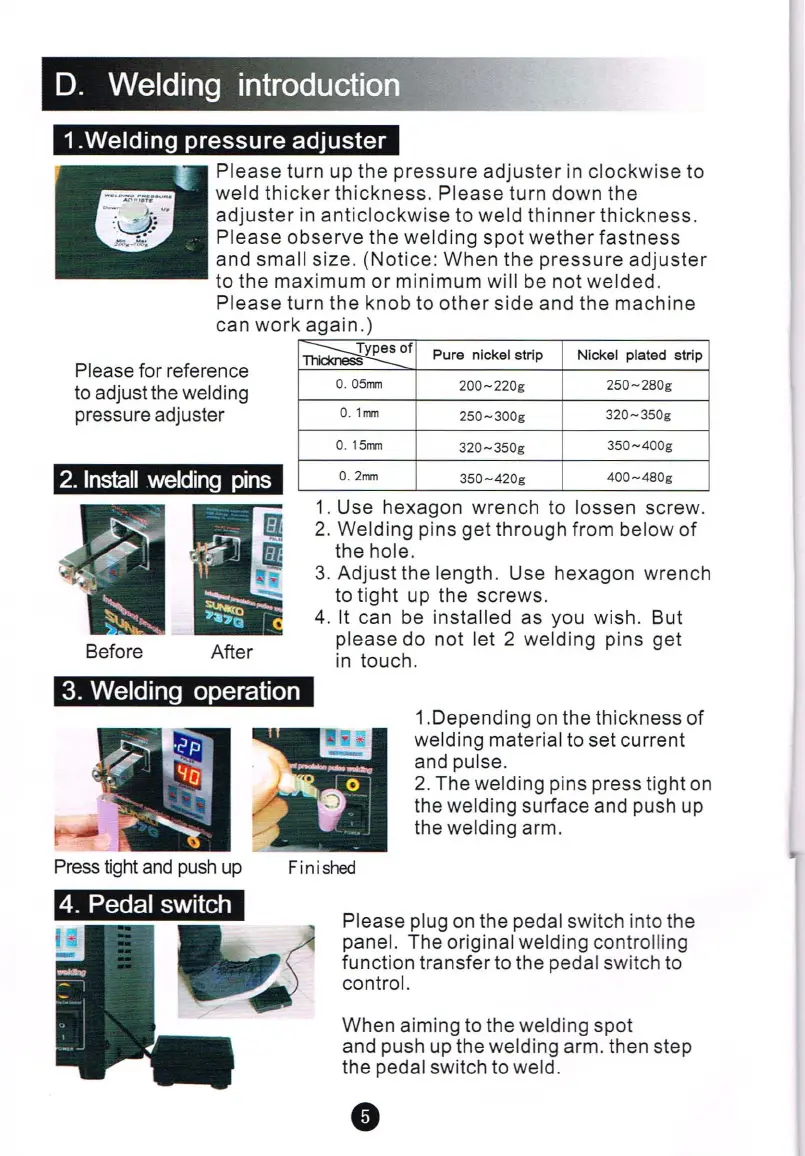

2.

Install

welding

pins

Before

After

3. Welding operation

O.

15rrrn

320-350g

350

- 40

0g

O.2rrrn

350-420g

400-480g

1. Use hexagon wrench to lossen

screw

.

2.

Welding pins

get

through from below

of

the hole.

3. Adjust the length. Use hexagon wrench

to

tight

up the screws.

4.

It can be installed as you wish. But

please do not let 2 welding pins get

in

touch.

1.

0epending

on

the thickness

of

welding material to set current

and pulse.

2.

The welding pins press tight on

the welding surface and push up

the welding arm.

Press

tight

and

push

up

Finished

4. Pedal switch

Please plug

on

the pedal switch into the

panel. The original welding controlling

function transfer to the pedal switch to

control.

When aiming to the welding spot

and push up the

welding arm. then step

the pedal switch to weld .

.,

Loading...

Loading...