MAXEONSOLARTECHNOLOGIES,LTD.

SafetyandInstallationInstructions‐Document001‐15497Rev.W

©December2021MaxeonSolarTechnologies,Ltd.Allrightsreserved.Specificationsincludedinthismanualaresubjecttochangewithoutnotice.

Shadingincidenceneedtobe avoidedduring PVsystem operation.

The system is not supposed to be energized until the mounting

scaffolding,fencesorrailinghavebeenremovedfromtheroof.

Systemsshouldbedisconnectedinanycasesofmaintenancewhich

can cause shading (e.g. chimney sweeping, any roof maintenance,

antenna/dish

installations,etc).

6.0Maintenance

Maxeon recommends visual inspection on a regular basis of all

modules for safe electrical connections, sound mechanical

connection,andfreefromcorrosion.Thisvisualinspectionshouldbe

performed by trainedpersonnel. The standard frequencyis once a

year according to environmental conditions, periodic cleaning of

modulesisrecommendedbutisnotrequired.Periodiccleaninghas

resulted inimproved performance levels, especiallyinregions with

lowlevelsofannualprecipitation(lessthan46,3cm(18,25inches)).

Consult your dealer or supplier about recommended cleaning

schedulesforyourarea.

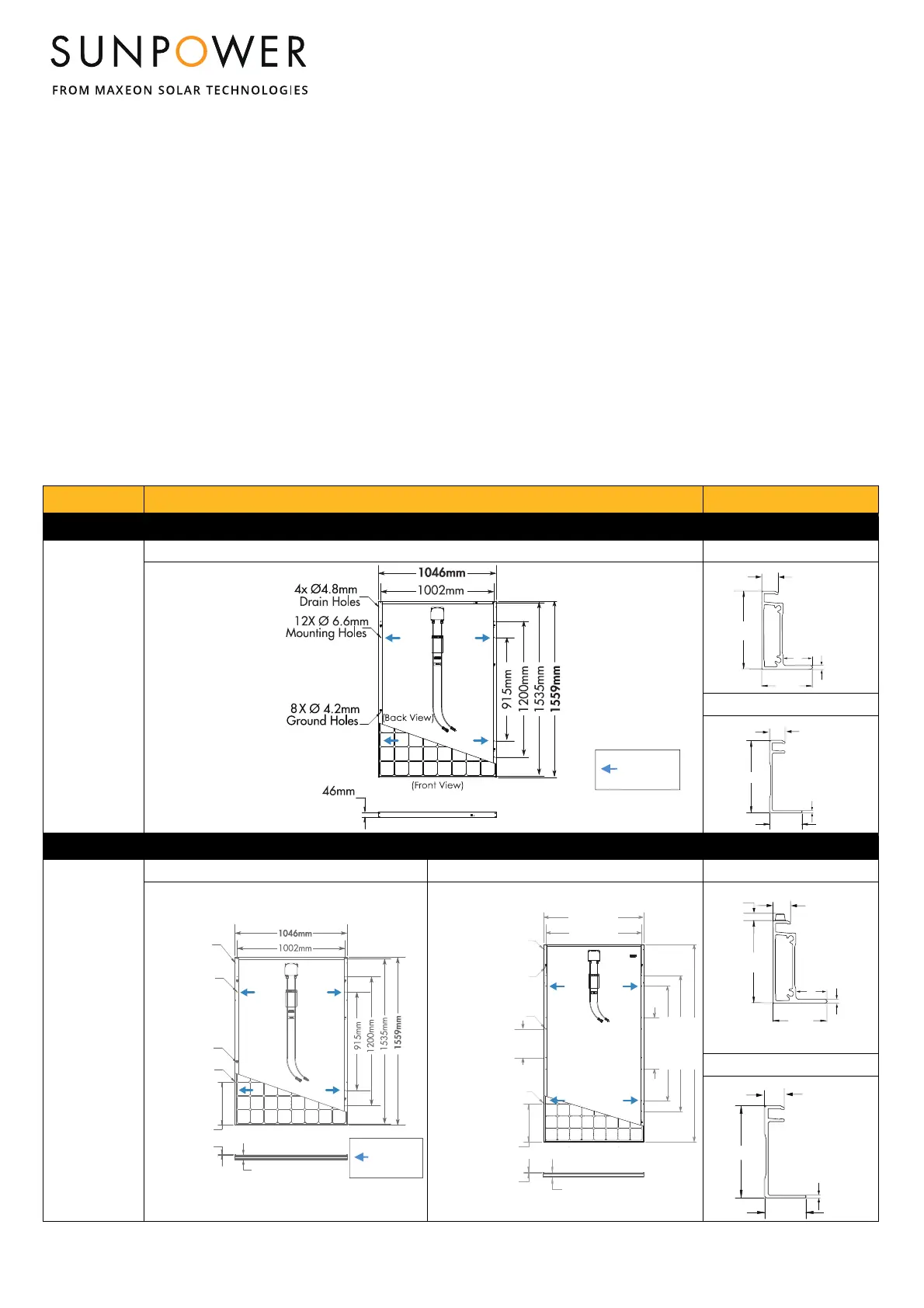

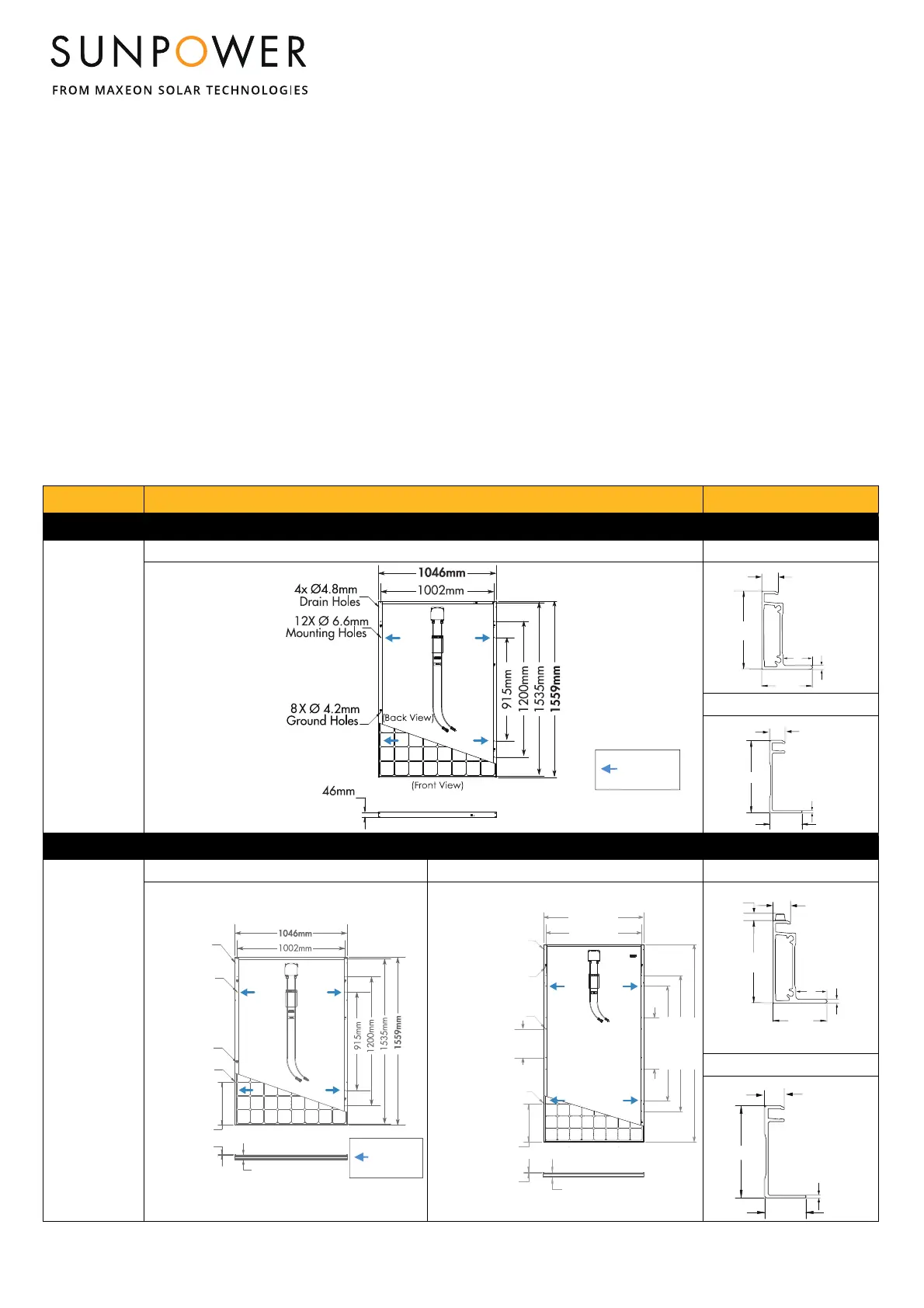

Table2:ModuleFrameDetails

Tocleanamodule,washwithpotable,non‐heated,water.Normal

waterpressureismorethanadequate,butpressurizedwaterupto

100 bar (min.50 cm distance) may be used. Maxeon recommends

usinga largehosepipeand nottoperformcleaningat highoutside

temperatures. Fingerprints, stains, or accumulations of

dirt on the

frontsurfacemayberemovedasfollows:firstrinseoffareaandlet

soakforashortperiodoftime(5mins).Re‐wetanduseasoftsponge

orseamlessclothtowipeglasssurfaceina circularmotion.

Fingerprintstypicallycanberemovedwithasoftclothorspongeand

water after wetting. Do not use harsh cleaning materials such as

scouring powder, steel wool, scrapers, blades, or other sharp

instruments to clean the glass surface of the module. Use of such

materialsorcleaningwithoutconsultationwillinvalidatetheproduct

warranty.AsdrycleaningisalsoriskyforAnti‐Reflective(AR)coated

module surface, spinning brush is not recommended for module

cleaning.

Platform Modulemountingandgroundholedetail FrameProfile

RESIDENTIALG3FRAMEONLY

Residential

Modules

96CELLMODULEFRAMEDETAIL SIDEFRAMEPROFILE

ENDFRAMEPROFILE

FORCOMMERCIAL(SILVERFRAME)MODULESONLY,INCLUDESSTACKINGPINS

Commercial

Modules

96CELLCOMMERCIALMODULE 128CELLCOMMERCIALMODULE SIDEFRAMEPROFILE

WithStackingPins

ENDFRAMEPROFILE

32 mm

46.08 mm

10.30 mm

18.50 mm

2.20 mm

22 mm

46.08 mm

10.50 mm

1.27 mm

4X Ø 4.8 mm

Drain Holes

12X Ø 6.6 mm

Mounting Holes

6X Ø 4.2 mm

Ground Holes

4X Ø 6.10 mm

Stackings Pins

3.2 mm

398 mm

46 mm

(Back View)

(Front View)

Stacking Pins

4X Ø6.10 mm

300 mm

20X Ø6.8 mm

Mounting Holes

4X Ø4.2 mm

Ground Holes

4X Ø4.8 mm

Drain Holes

398 mm

3,2 mm

46 mm

(Front View)

(Back View)

1046 mm

1002 mm

2067 mm

1200 mm

1423 mm

539 mm

32 mm

46.08 mm

3.18 mm

10.30 mm

18.50 mm

2.20 mm

22 mm

46.08 mm

10.50 mm

1.27 mm

MeasurementTolerancesare+/‐3mmfortheLengthandWidthoftheModule.

Method 1:

Frame Hole

Locations

Method 1:

Frame Hole

Locations

Loading...

Loading...