SUNPOWER CORPORATION

Safety and Installation Instructions - Document 001-14158 Rev AG

© 2020 SunPower Corporation. All rights reserved. Specifications included in these instructions are subject to change without notice. Page | 3

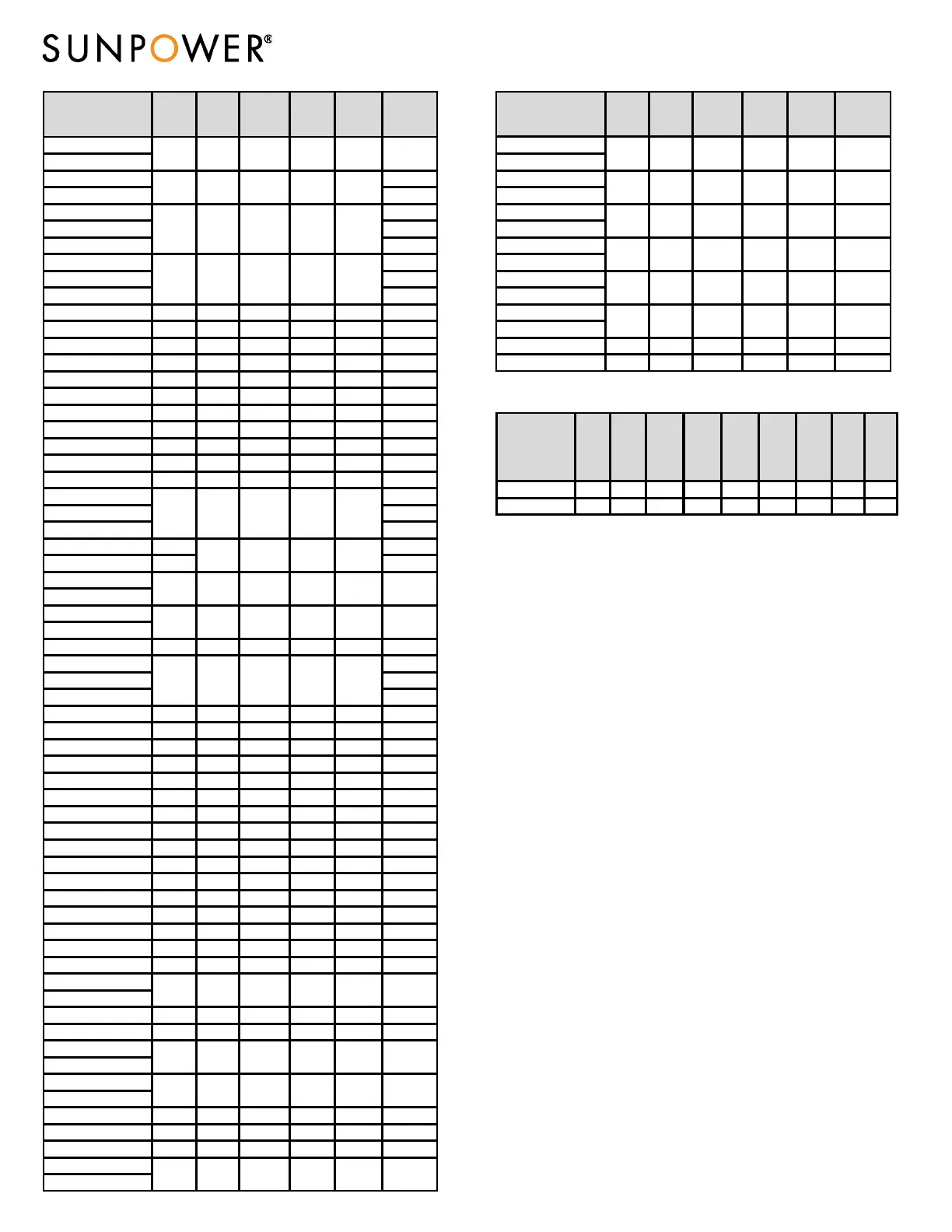

Module

Rated

Power (W)

Voltage at

Rated

Power

Vmpp (V)

Current at

Rated Power,

Impp (A)

Open

Circuit

Voltage

Voc (V)

Short Circuit

Current, Isc

(A)

Maximum

System

Voltage UL

Vmax (V)

SPR-X21-335

SPR-X21-335-BLK

SPR-X19-315-COM 1000

SPR-X19-315-BLK 600

SPR-X20-327-COM 1000

SPR-X20-327 600

SPR-X20-327-BLK 600

SPV-X19-310-COM 1000

SPR-X19-310 600

SPR-X19-310-BLK 600

SPR-X22-360-COM-MLSD 360 59.1 6.18 69.5 6.66 1000

SPR-X21-345-COM-MLSD 345 57.3 6.02 68.2 6.39 1000

SPR-X21-335-COM-MLSD 335 57.3 5.85 67.9 6.23 1000

SPR-X20-327-COM-MLSD 327 57.3 5.71 67.6 6.07 1000

SPR-E20-450-COM 450 72.9 6.18 86.5 6.65 1000

SPR-E20-445-COM 445 72.9 6.11 86.5 6.57 1000

SPR-E20-440-COM 440 72.9 6.04 86.5 6.5 1000

SPR-E20-435-COM 435 72.9 5.97 85.6 6.43 1000, 1500

SPR-E19-420-COM 420 72.9 5.77 85.6 6.20 1000

SPR-E19-410-COM 410 72.9 5.62 85.3 6.01 1000

SPR-E21-340-COM 340 54.7 6.21 64.9 6.71 1000

SPR-E20-327-BLK 600

SPR-E20-327 600

SPR-E20-327-COM 1000

SPR-E19-320 320 600

SPR-E19-320-COM 320 600

SPR-E19-315

SPR-E19-315-BLK

SPR-E19-310-COM

SPV-E19-310-COM

SPR-E18-305 305 54.7 5.58 64.2 5.96 600

SPR-E18-300-COM 1000

SPR-E18-300-BLK 600

SPR-E18-300 600

SPR-E18-295-COM 295 54.2 5.45 63.3 5.83 1000

SPR-E20-330-COM 330 54.7 6.04 64.9 6.52 1000

SPR-E20-330-COM-MLSD 330 54.7 6.04 64.9 6.52 1000

SPR-E20-327-COM-MLSD 327 54.7 5.98 64.8 6.46 1000

SPR-E19-320-COM-MLSD 320 54.7 5.86 64.7 6.24 1000

SPR-P19-400-COM 400 43.4 9.22 52.7 9.80 1500

SPR-P19-395-COM 395 43.2 9.14 52.5 9.72 1500

SPR-P19-390-COM 390 43.1 9.05 52.3 9.64 1500

SPR-P19-385-COM 385 42.8 8.99 52.0 9.58 1500

SPR-P19-380-COM 380 42.6 8.92 51.8 9.49 1500

SPR-P19-380-COM-MLSD 380 43.3 8.78 52.2 9.43 1500

SPR-P19-385-COM-MLSD 385 43.8 8.80 52.5 9.44 1500

SPR-P19-390-COM-MLSD 390 44.1 8.85 52.9 9.45 1500

SPR-P19-395-COM-MLSD 395 44.4 8.90 53.4 9.47 1500

SPR-P19-400-COM-MLSD 400 44.8 8.93 53.6 9.5 1500

SPR-A430-COM 430 42.7 10.1 51.2 10.9 1500

SPR-A440-COM

SPR-A440-COM-MLSD

SPR-A450-COM 450 44.0 10.2 51.9 11.0 1500

SPR-A450-COM 450 44.0 10.2 51.9 11.0 1500

SPR-A390

SPR-A390-BLK

SPR-A400

SPR-A400-BLK

SPR-A410 410 40.0 10.2 48.2 10.9 1000

SPR-A415 415 40.3 10.3 48.2 10.9 1000

SPR-A420 420 40.5 10.4 48.2 10.9 1000

SPR-MAX2-360

SPR-MAX2-360-COM

335 57.3 5.85 67.9 6.23 600

400 39.5 10.1 48.1 10.9 1000

390 39.0 10.0 48.0 10.8 1000

440 43.4 10.2 51.6 10.9 1500

1000

327 54.7 5.98 64.8

54.7

54.7 5.67 64.4 6.05

5.87

5.82

5.86 64.7 6.24

310

6.46

310 57.3 5.41

6.07

67.2

300 54.7 5.49 64.0

327 57.3 5.71 67.6

315 54.7 5.76 64.6 6.14 600

360 59.1 6.09 70.6 6.50 1000

315 57.3 5.50 67.3 5.9

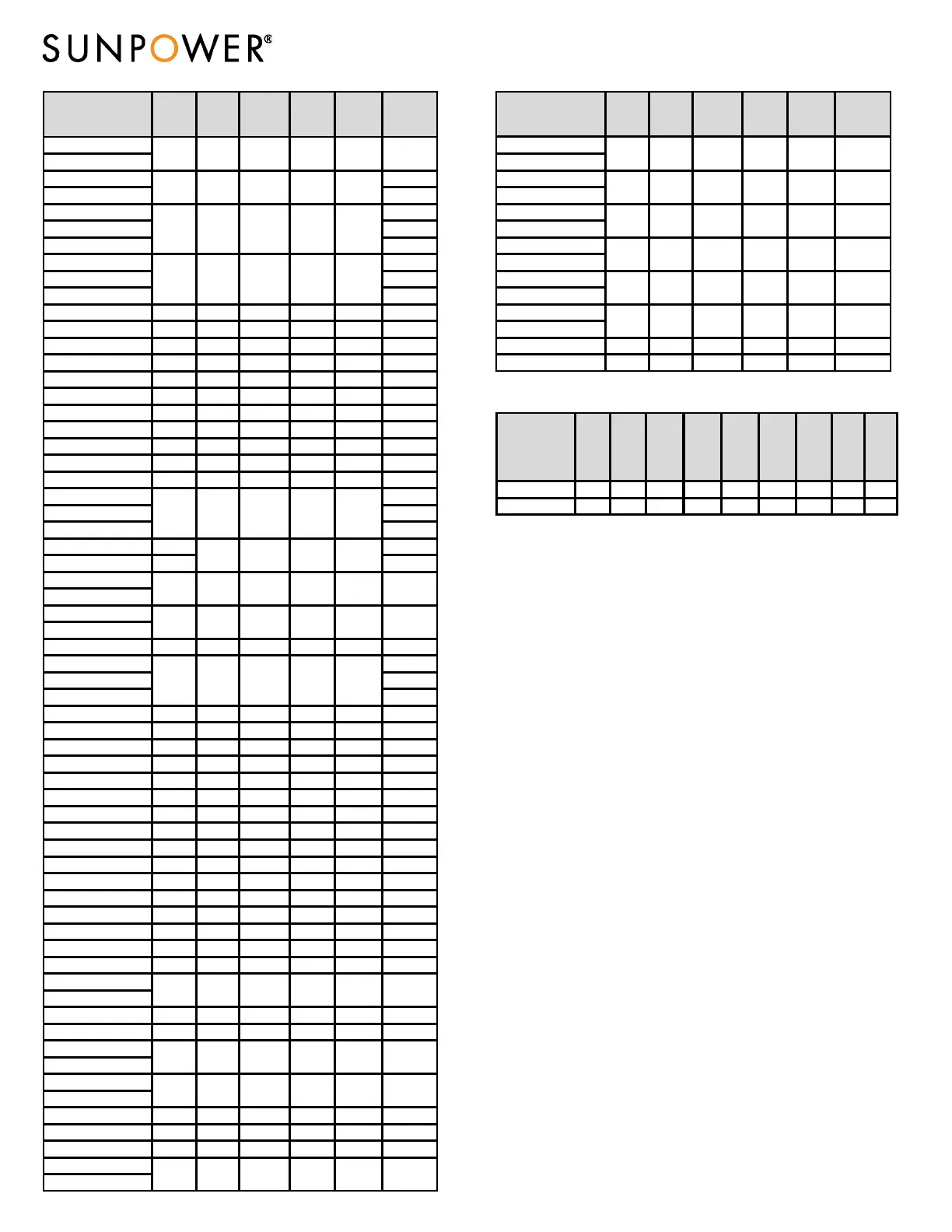

Module

Rated

Power (W)

Voltage at

Rated

Power

Vmpp (V)

Current at

Rated Power,

Impp (A)

Open

Circuit

Voltage

Voc (V)

Short Circuit

Current, Isc

(A)

Maximum

System

Voltage UL

Vmax (V)

SPR-MAX2-350

SPR-MAX2-350-COM

SPR-MAX2-340

SPR-MAX2-340-COM

SPR-MAX3-400

SPR-MAX3-400-COM

SPR-MAX3-395-COM

SPR-MAX3-395

SPR-MAX3-390

SPR-MAX3-390-COM

SPR-MAX3-370

SPR-MAX3-370-COM

SPR-MAX3-375-BLK 375 62.5 6.00 74.9 6.52 1000

SPR-MAX3-355-BLK 355 59.8 5.94 74.3 6.49 1000

350 57.9 6.05 70.3 6.48 1000

400 65.8 6.08 75.6 6.6 1000

370 61.8 5.99 74.7 6.52

1000

1000

1000

6.55390 64.5 6.05

6.56

75.3

395 65.1 6.07 75.4

340 56.6 6.00 70.0 6.46 1000

UL 61730 Certified Models

Module

Rated

Power

(W)

+5/-0%

Voltage

at Rated

Power

Vmpp

(V)

Current

at Rated

Power,

Impp (A)

Open

Circuit

Voltage

Voc (V)

+/-3%

Short

Circuit

Current,

Isc (A)

+/-3%

Current

Temp.

Coeff.

%/°C

Voltage

Temp.

Coeff.

%/°C

Power

Temp.

Coeff.

%/°C

System

Safety

Class

SPR-A400-BLK 400 39.5 10.1 48.1 10.9 0.060 -0.239 -0.30 II

SPR-A390-BLK 390 39.0 10.0 48.0 10.9 0.060 -0.239 -0.30 II

4.0 Electrical Connections and System Monitoring

Modules may be connected in series or parallel to achieve the desired electrical

output provided certain conditions are met.

SunPower recommends using the same brand connector in a given PV system.

Currently approved compatible connectors found on SunPower modules are:

Tyco Solarlok PV4 and PV4S, Yukita (YS-254/YS-255), Multi-Contact MC4

(PVKBT4/6II, PVKST4/6II) and Staubli Electrical Connectors (PVKST4/6II-UR,

PVKBT4/6II-UR). SunPower warrants the connectors delivered on SunPower

supplied modules and harnesses as being compatible.

4.1 Equipment Grounding

To reduce the possibility of electrical shock, ground the frame of the module or

array per NEC before wiring the circuit. In order to install in accordance with their

UL Listing, SunPower modules must be grounded using grounding hardware that

meets requirements for grounding systems in UL 467, UL 1703, or UL 1741; on

anodized aluminum frames. SunPower recommends using one of the following

methods of grounding the module frame. In addition, to avoid corrosion due to

the use of dissimilar metals SunPower recommends stainless steel between

copper and aluminum. For the Generation 5 (G5) frame, only methods 1 and 2

apply. A-Series -BLK modules must be installed with the Ground Lug Assembly of

the Invisimount mounting system using the Ilsco GBL-4DBT grounding lug

tightened to a torque of 85 in-lbs to bond the module frame to the rail. The rails

used for bonding must be part of the system’s ground path.

1) Attach a lay-in lug (Ilsco GBL-4DBT, Burndy CL50-DB-T or Tyco Solklip 1954381-

2) to one of the grounding holes on the module frame, and attach the

ground conductor to the lug. Use stainless steel hardware (bolt, washers,

and nut). Use an external-tooth star washer between the lug and the

module frame in order to pierce the anodizing and establish electrical

contact with the aluminum frame. The assembly must end with a nut that’s

torqued to 20–25 in-lb (for a #10-32 bolt). A lock washer or other locking

mechanism is required to maintain tension between the bolt and the

assembly. The conductor must be attached to the ground lug using the lug’s

set screw. Refer to NEC 690.

2) SunPower modules may also be grounded through the use of SunPower IFF

clips which are UL Listed (1703 and 1741). IFF clip torque value is 35–45 in-

lbs for a 1/4-20 or M6 bolt, but may be higher in specific applications.

When using IFF clips, the module mounting system must be grounded as

per NEC 250.

Note: Method 3 is evaluated to UL 1703 by ETL. As such, the use of these devices

is not considered part of the UL Listing of these modules.

Loading...

Loading...