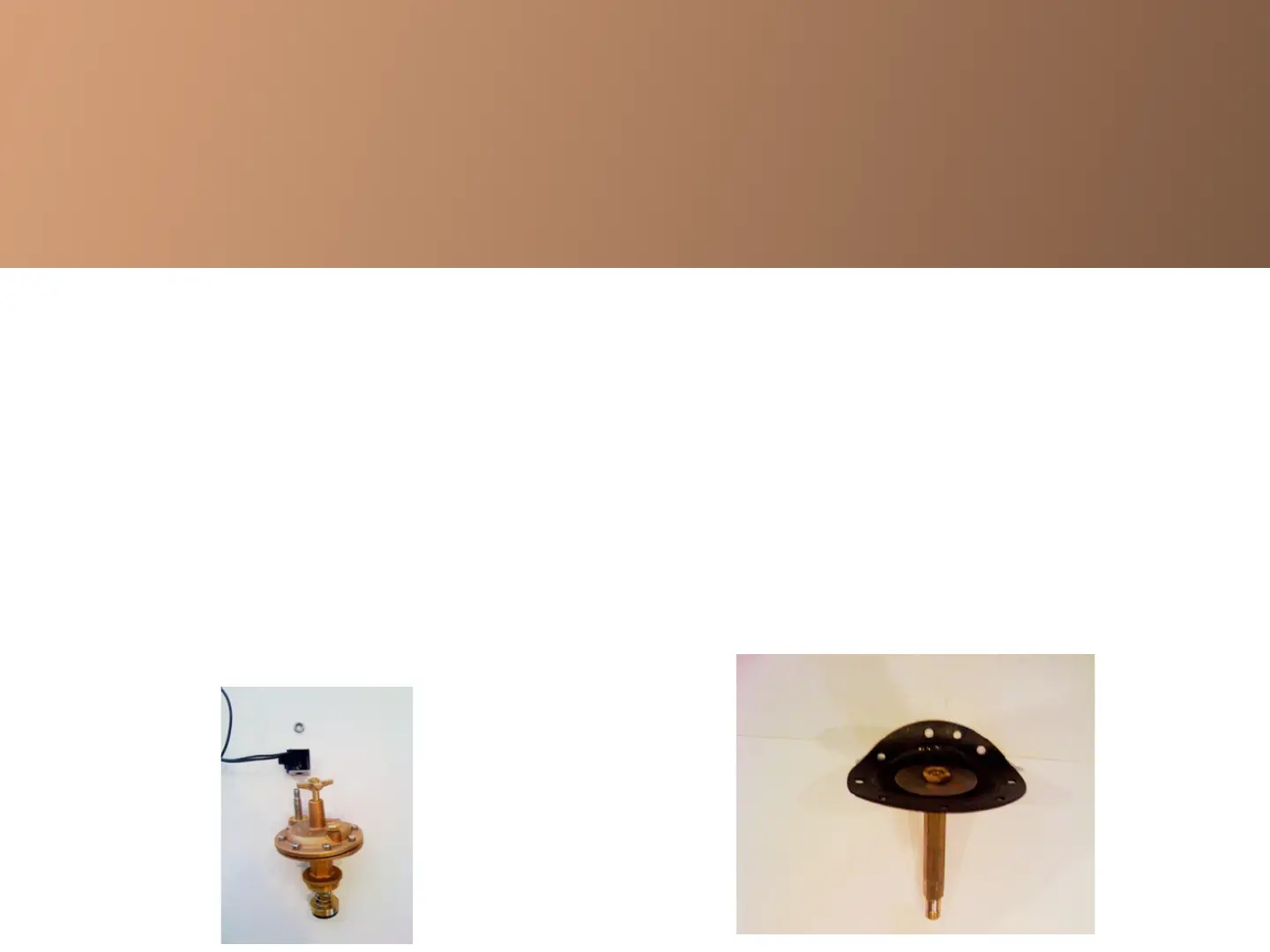

CAUSE #1:

Solenoid is not receiving power

SOLUTION:

Place your fingers around the solenoid

coil to see if it is receiving power. There should

be a slight vibration and humming. If not, verify

that there is output at the controller by using a

volt meter. If there is electrical output (24 VAC)

then the problem is either a bad coil or broken

wire. Check the coil by disconnecting solenoid

lead wires from valve wires and measure ohms

with an ohm meter. A reading of 24 to 27 ohms

means the coil is OK. If reading is 0 or infinity,

replace coil.

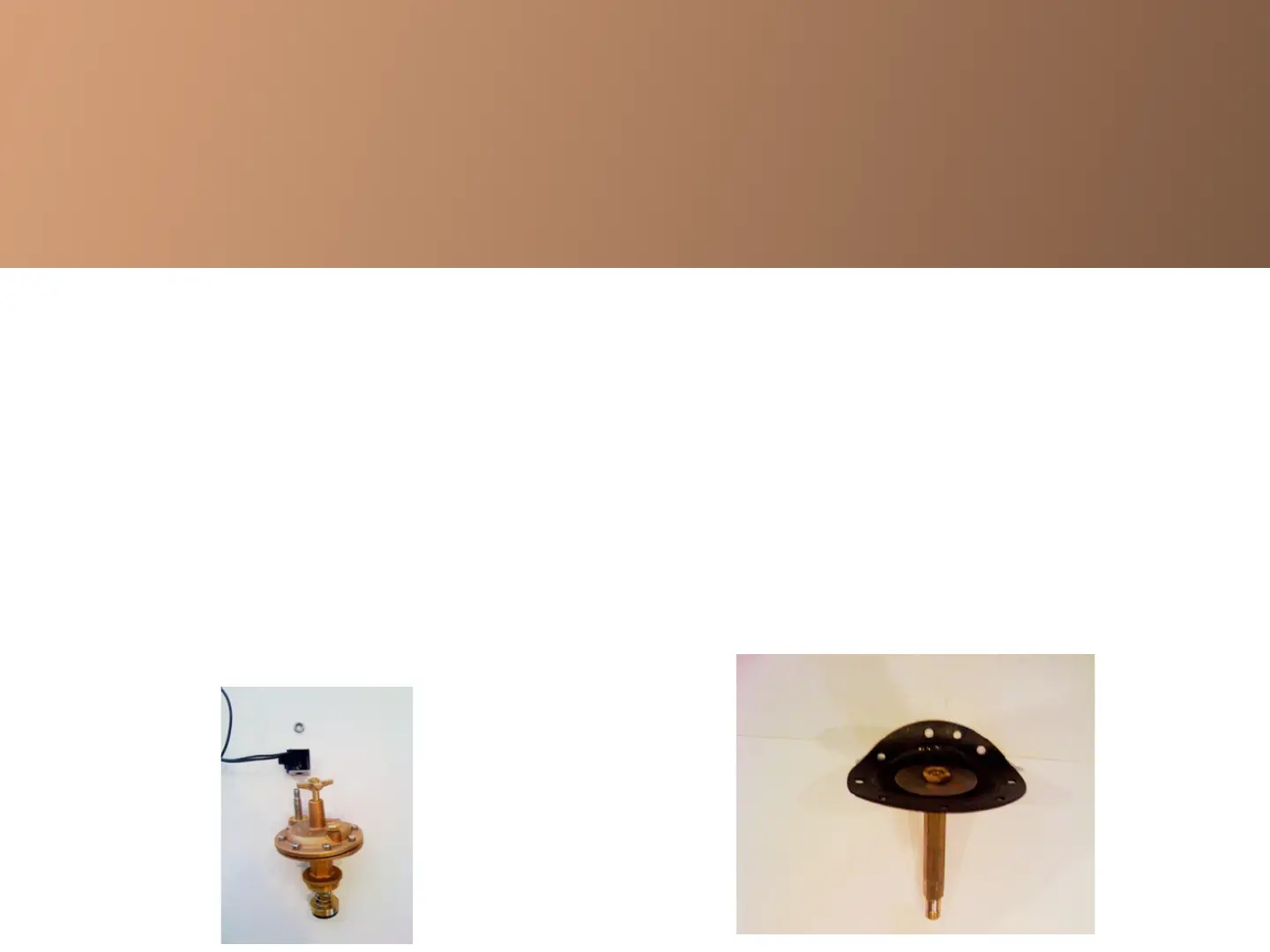

CAUSE #2:

Enlarged inlet orifice at bottom of

diaphragm shaft is allowing water to enter

diaphragm chamber at a rate greater

than it can exit through solenoid exhaust

port. Because the inlet orifice is brass, it

can enlarge over time in high

pressure/velocity conditions.

SOLUTION:

Replace diaphragm assembly (which

includes diaphragm shaft) or replace

adaptor.

14

Troubleshooting

PROBLEM: Valve will not open

when energized.

Loading...

Loading...