ENGINE 3-29

• Tighten the camshaft journal holder bolts evenly and diago-

nally to the specified torque.

" Camshaft journal holder bolt: 10 N·m (1.0 kgf-m)

NOTE:

Do not rotate the camshaft with the plastigauge in place.

• Remove the camshaft holder, and read the width of the com-

pressed plastigauge with envelope scale. This measurement

should be taken at the widest part.

• If the camshaft journal oil clearance measured exceeds the

limit, measure the inside diameter of the camshaft journal

holder and outside diameter of the camshaft journal.

• Replace the camshaft or the cylinder head depending upon

which one exceeds the specification.

% Camshaft journal holder I.D.:

Standard: (

(

22) 22.012 – 22.025 mm

(

(

17.5) 17.512 – 17.525 mm

$ 09900-20602: Dial gauge (1/1 000 mm)

09900-22401: Small bore gauge (10 – 18 mm)

09900-22403: Small bore gauge (18 – 35 mm)

% Camshaft jouranal O.D.:

Standard: (

(

22) 21.959 – 21.980 mm

(

(

17.5) 17.466 – 17.484 mm

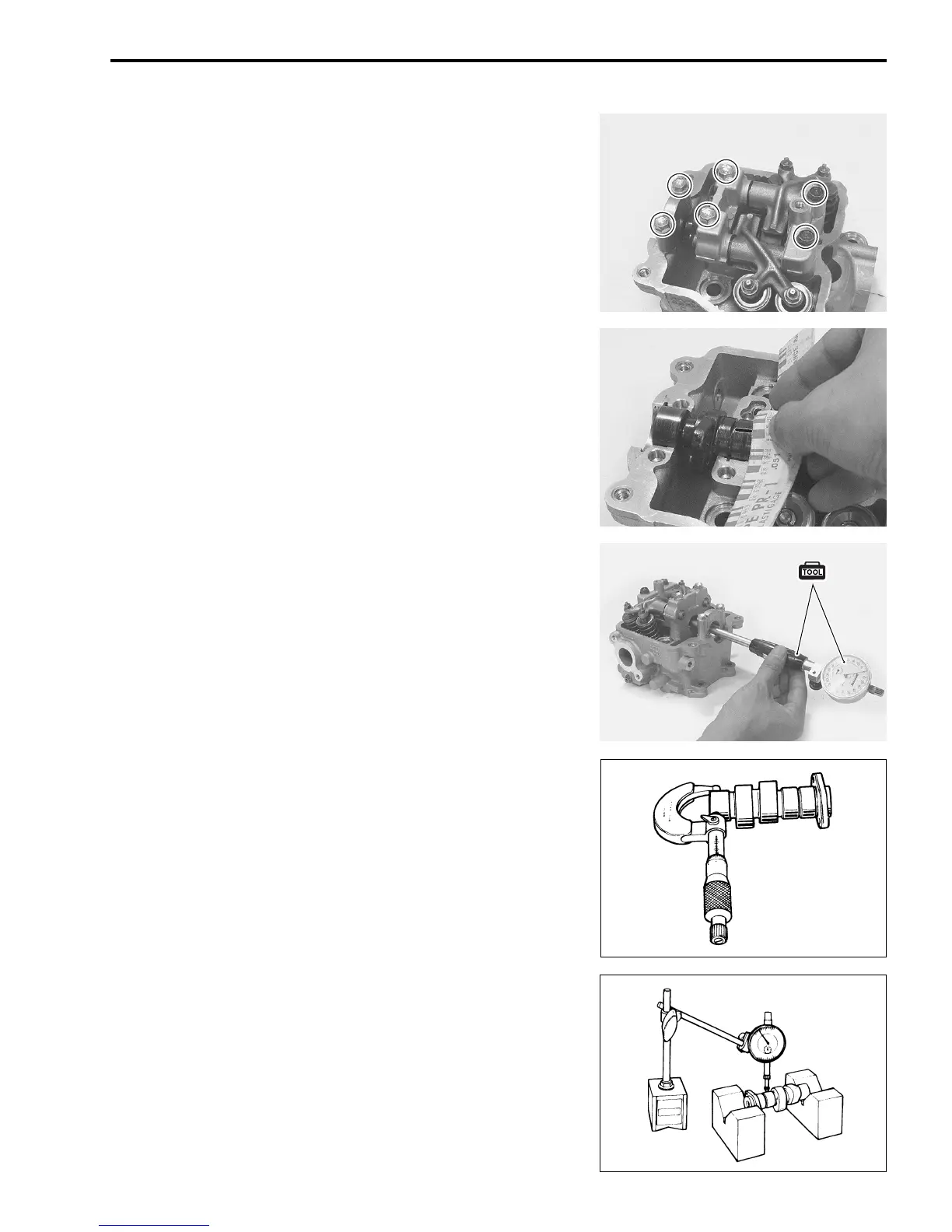

$ 09900-20205: Micrometer (0 – 25 mm)

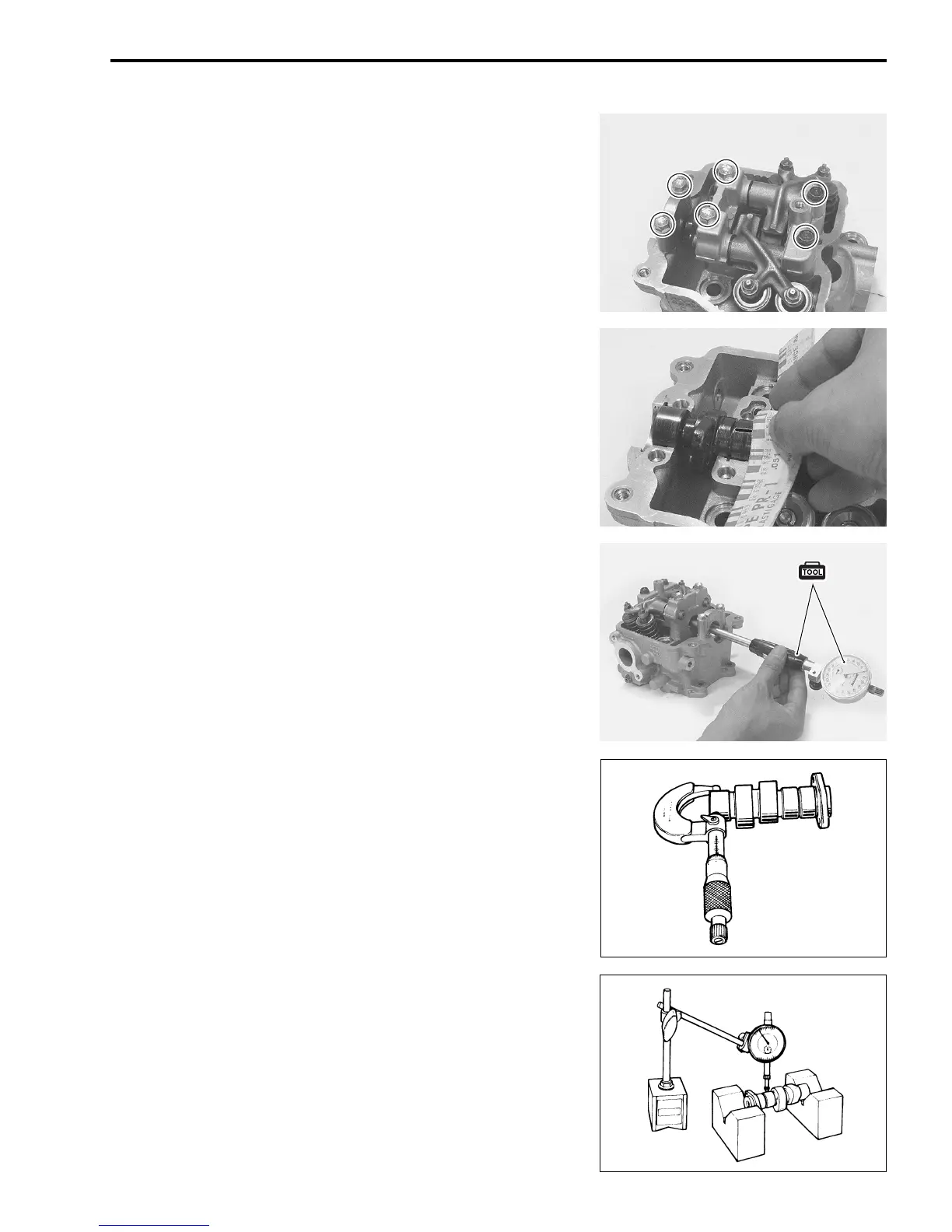

CAMSHAFT RUNOUT

• Measure the runout using the dial gauge.

• Replace the camshaft if the runout exceeds the limit.

% Camshaft runout:

Service Limit: 0.10 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block (100 mm)

Loading...

Loading...