CE300AF

Page 4 of 15

04

Operating Risk / Safety

04.A E-Stops

Located on manual motor starter at front of machine. When

pressed, will de-energize entire system. Once pressed, button

must be twisted clockwise to reset system.

04.B Lockout

Never operate or remove any system components that are

secure unless the system is electrically locked out and all

moving parts are motionless.

04.C Material Discharge

Do not place hands or stand near material discharge area of

machine, as the material is ejecting at high velocities.

04.D

Machine Infeed

Opening

While rare, it is possible for processed material to kick out of

infeed funnel. Stand to the side when feeding material into

machine. Do not look into the infeed funnel when the machine is

running. Keep hands out of infeed funnel, as it presents a

pinch/crush hazard.

04.E

Entanglement

Hazard

When feeding material into the system, be cautious of

entanglements in the scrap material as it is draw into the infeed

funnel. This material can hook on clothing and wrap around

body parts, pulling the operator towards the machine. If

entangled, pull on feedworks handle to open feedworks

mechanism.

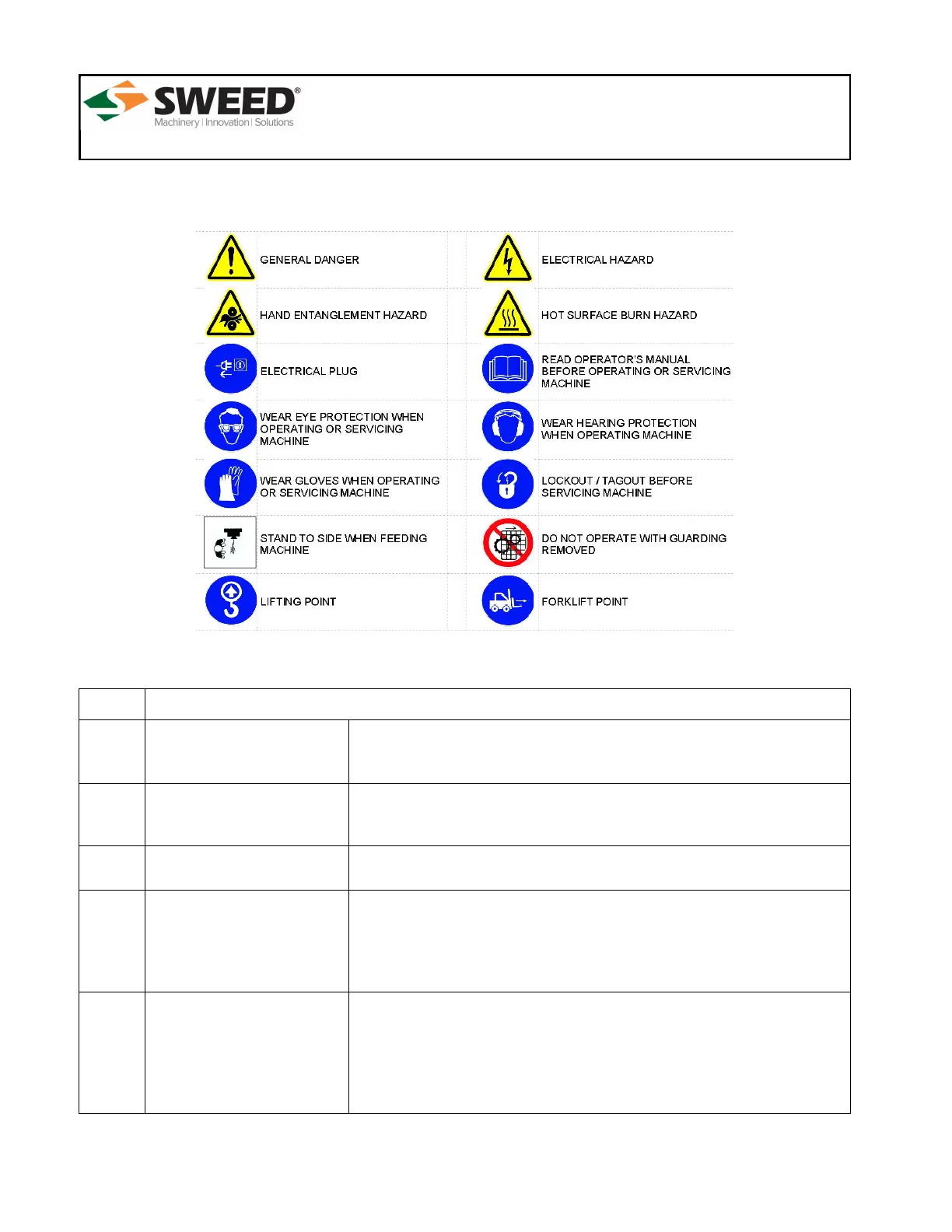

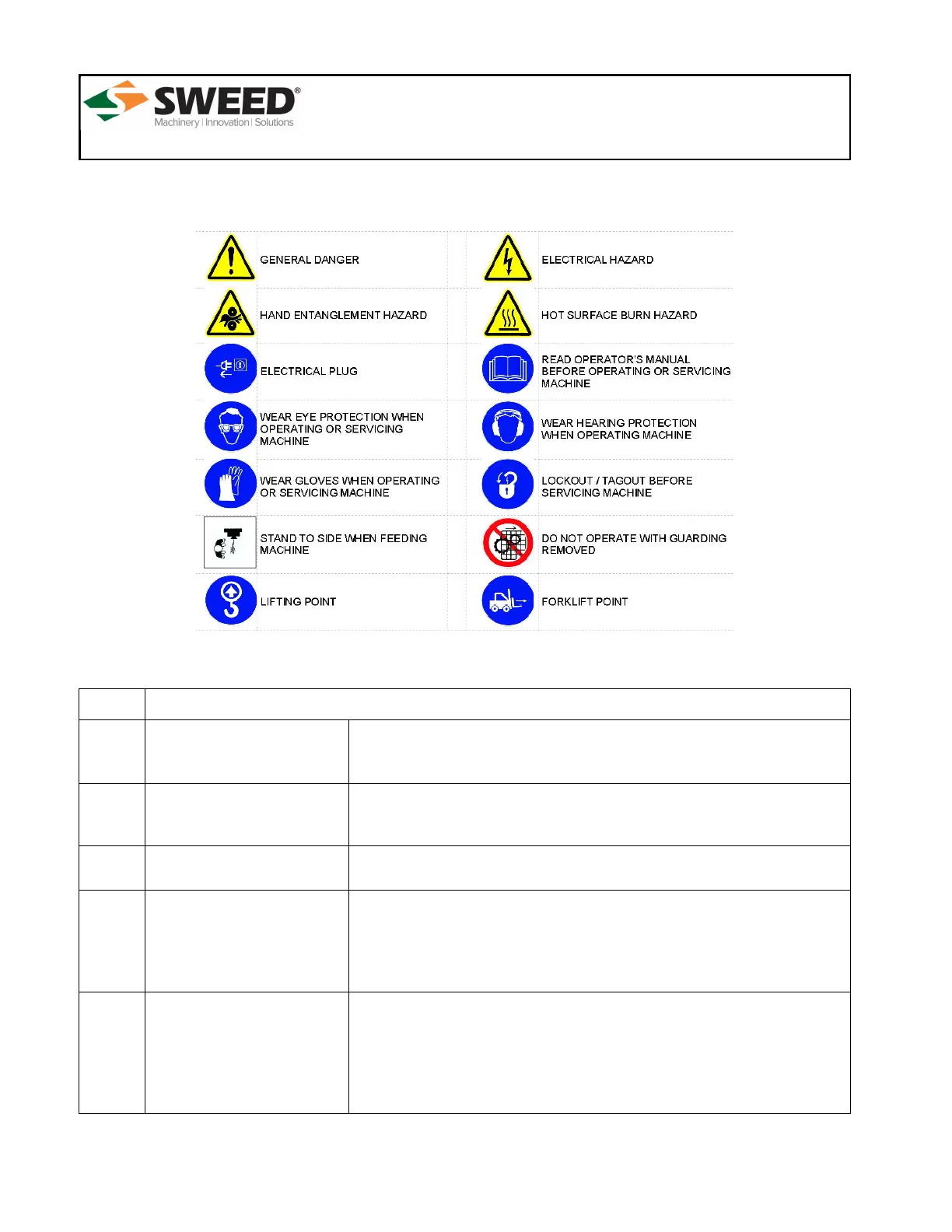

Sweed Machinery Machine Labels

Loading...

Loading...