8 How to check and reset the Upper Dead /Needle point.

(1) Check Needle Point

Turn the Main Shaft and put down Needle Bar for fixing it as 201 degree.

(2) Insert Needle Point JIG to between Bed Upper Head and bed and then check the gap.

If there is a gap,loosen the Needle Bar Bolt,push and down the Needle Bar for attaching to JIG, Tighten

Needle bar Bolt with T-Wrench .Shake JIG Up/Down for checking the gap.

(3) Set Upper Dead Point

1)Fix the main shaft as 0 de

ree

ush Needle Bar and

ut u

the U

er Dead Point Sto

er for ti

htenin

Bo

Grab Upper Dead Point and shake it up/down for checking gap.

If there is a gap, Needle Bar will be stumble.

Don't put up hardly and set for without gap.(When driving, these matters cause noise)

9 How to check Rotary Hook Timing and adjust.

※ Before setting the Rotary Hook, check the Needle twisted or not first, set the Needle forward direction

(Optimized Loop formating Condition)

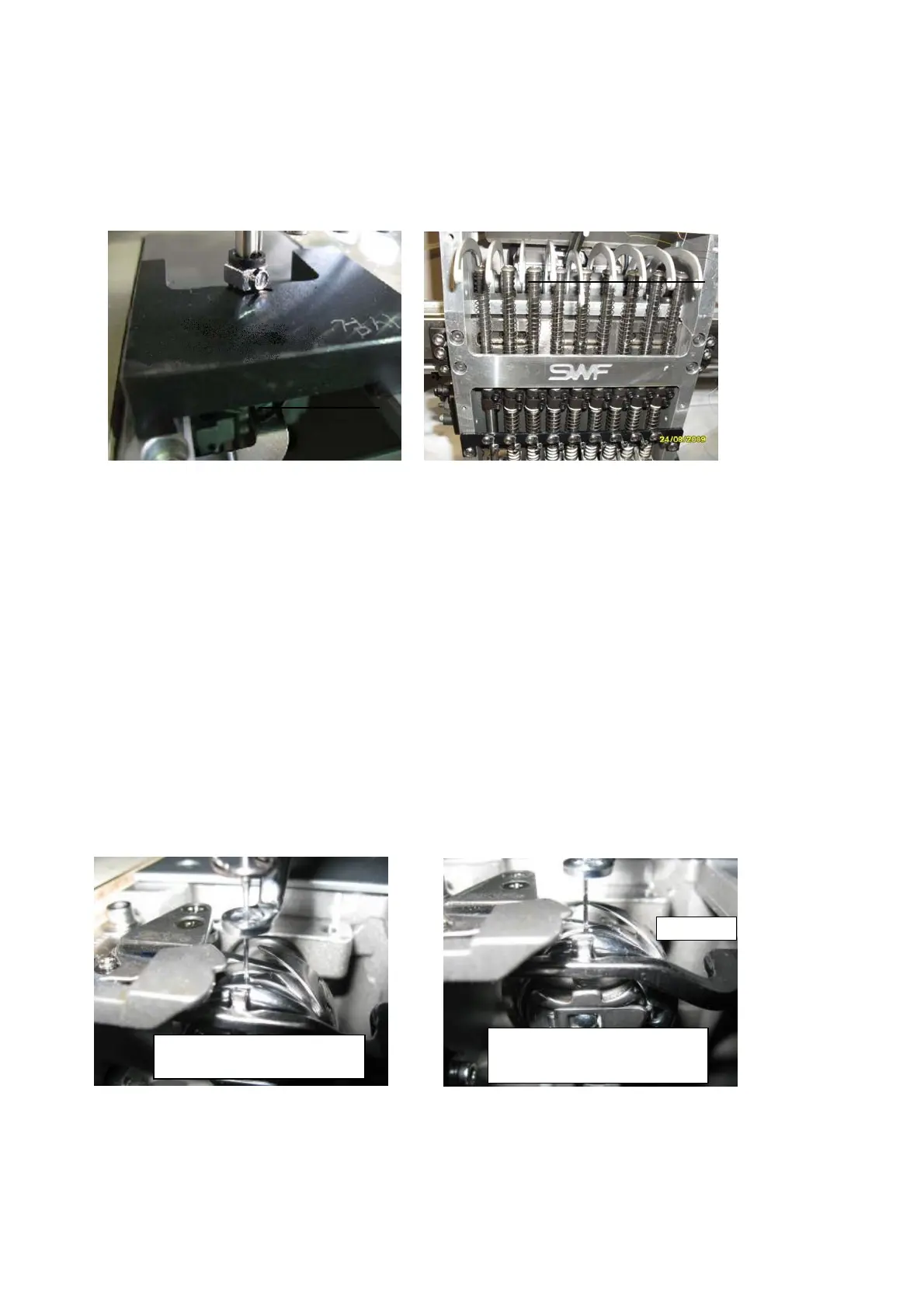

(1) Check/adjust Rotary Hook timing and gap.(with "-" driver)

From the middle Needle Bar , loosen 2(each)screw of Rotary Hook Fixed Screw 3 each(near 135°,75°).

Fix the main Shaft at 201° for checking the Point of Rotary Hook and Needle,gap.

If Point of Rotary Hook is not correct or gap(Needle and Rotary Hook) is big or too small, reset it.

After finish the setting,check First to Last Needle Bar of gap.And then tighten whole Screw.

(2) Check/adjust the position of Rotary Hook.

Adjust bulge part for being on Middle of the Needle, interval 0.5~0.7mm with Rotary Hook is needed

,by loosening Fixed Screw.

Adjust bulge part for being on Middle

of the Needle, interval 0.5~0.7mm

with Rotary Hook is needed.

Rotary Hook

Set Rotary Hook Point behind

Needle Bar at 0.1~0.3mm interval.

Page 14 Of 17 (주)SUNSTAR SWF CS Center

Loading...

Loading...