7 How to check Needle Position and correct.

(1) Check Head gap

1) Check F/R gap from No.3 Needle Bar

2) Change the Needle Bar by No.1 needle bar

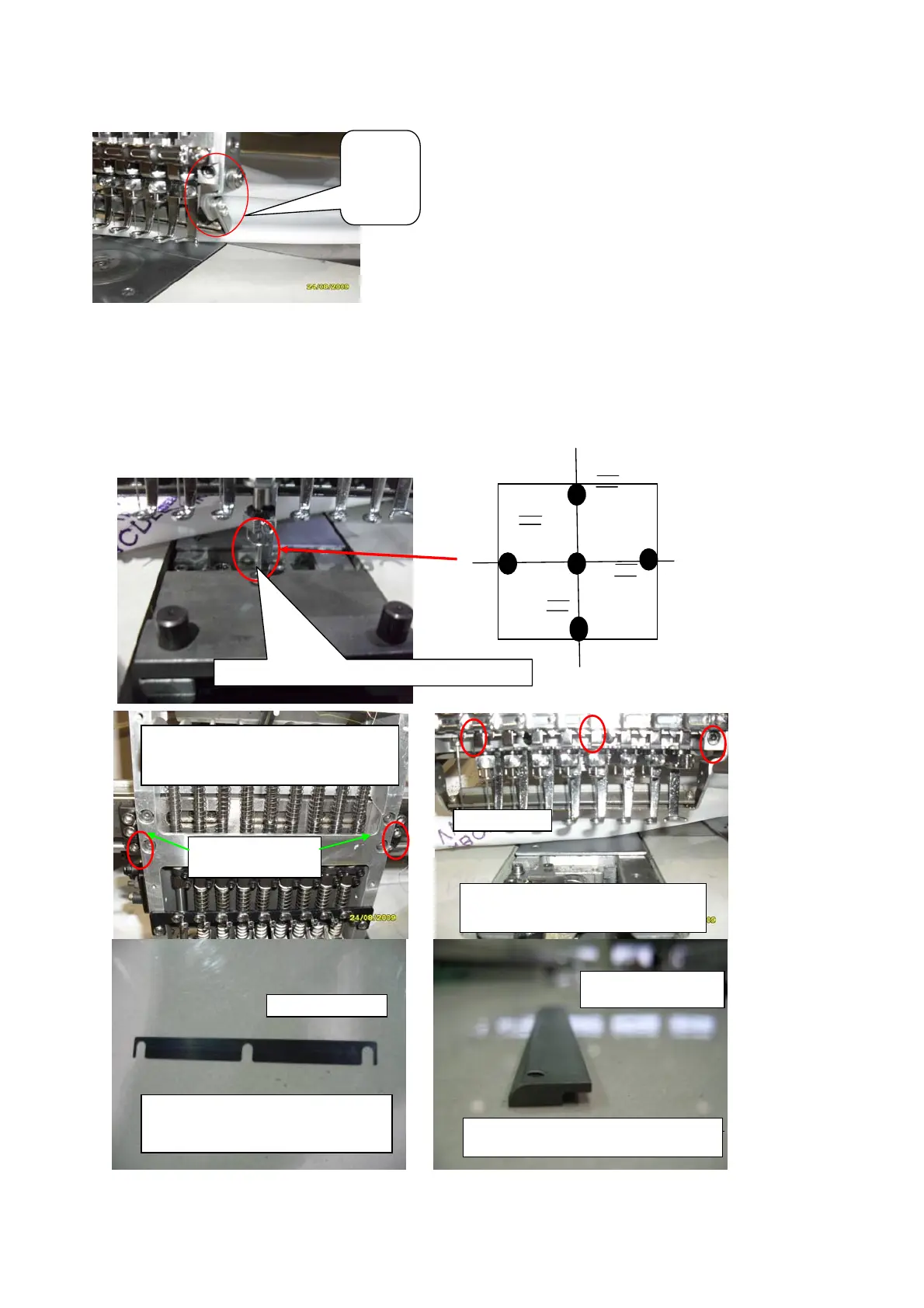

(2) Check Needle Position

1) Set the L/R Needle Position first and then F/R after.(with 3mm T Wrench)

If it is on ③ ,change the Head Rail for small one for adjustiong position.

If it is on ④, insert Gage of B.D.P between Head Rail and Head for adjusting.

2)After adjusting,check needle position between No.1 Needle and Last Needle.

※ If head gap is too much,Cutting Thread and

needle broking may occur. If gap is too

less,resistance problem will be happened( C/C).So

set the machine as minimum gap of it.

3 If F/R gap occurred,with M3 Wrench,set the

gap scope under 0.1mm(minimum)

Open the

M3 Bolt and

set head

gap.

COLOR CHANGE

SHAFT BRACKET

When adjusting ③,④ position, loosening

Head Rail Bolt (3 each)3mm with T-

wrench.

If it is placed ①,②, loosen the COLOR

CHANGESHAFTBRACKETBoltforadjusting

NeedlepositionL/R

.

Head Rail Bolt

The hall size of Zig is length,width each

If the needle is on ④, insert Guage to

between Head Rail and Head

for adjusting.(with 0.1T,0.2T,0.3T)

If the needle is on the ③ ,replace it with thin

Head Rail for adjusting.

Head Rail Guage

Replace 4.5T

4.3 ,4.0 T as base

Page 13 Of 17 (주)SUNSTAR SWF CS Center

Loading...

Loading...