4

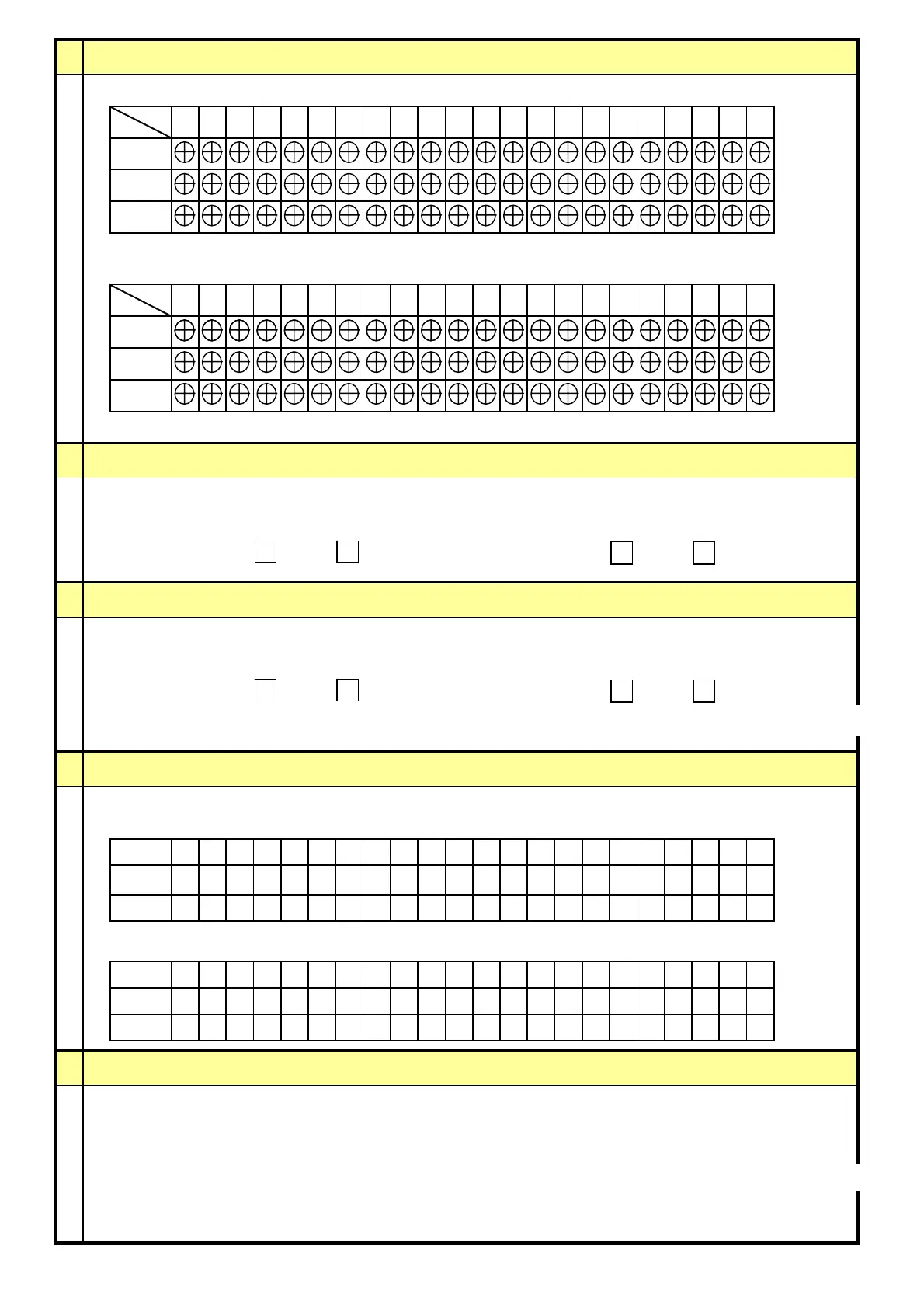

Check B.D.P status and adjusting

① Before

12345678910111213141516171819202122

② After

12345678910111213141516171819202122

※ When insert guage,record it.

5

Check list for Hook timimg and adjusting(good:O, bad:X )

Hook timing 201°, No gapss with Needle, more than 0.3mm,reset it.

① Before ② After

good bad good bad

6

Check list for checking the Pressor Foot and set (good:O, bad:X )

General Head - If needle bar(180 °

) is out of 1.2mm from Upper Face,reset it.

① Before ② After

good bad good bad

※ Able to ad

ust

de

ends on

roduct (deliver

Data : 1.2mm

Thin Fabric:0.7mm이하

Thick Fabric:

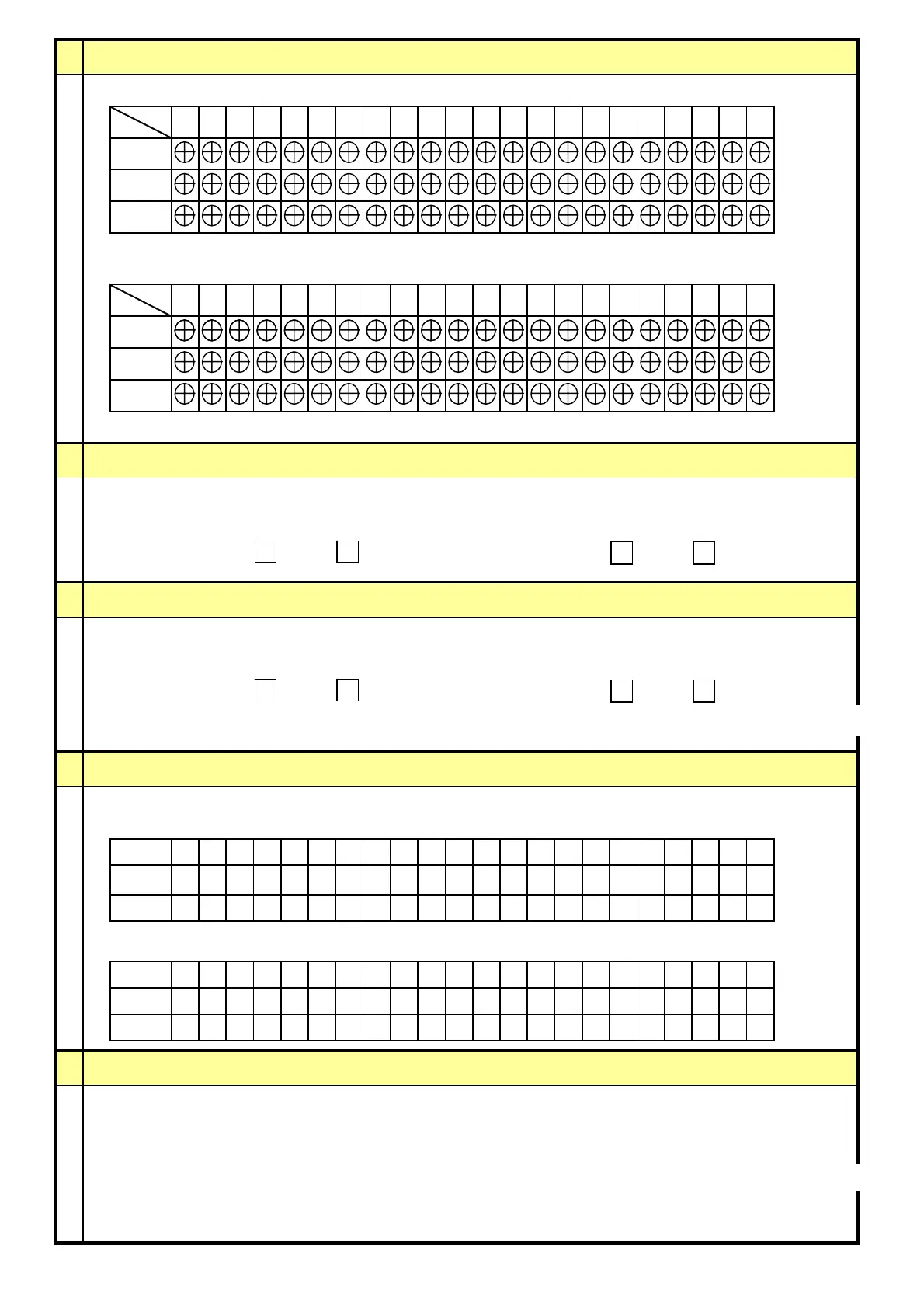

7

Check list for checking Upper Dead/Needle position and setting

General Head - If Needle point 201°,Upper Dead Point 0° is not correct,reset it.

① Before

12345678910111213141516171819202122

② After

12345678910111213141516171819202122

8

Sewing TEST.

※ Test with thread and fabrick from your company and check Status of machine

Check Nomalization status,cutting thread

(If the Agent didn't prepare desing,test it with workplace sewing design and check)

※ When test Sewin

, check the cuttin

thread, work timek,missin

the first needle and then re

or

Attach the Sample and Design to report.

※When Sewing TEST,train the worker and manager that how to operate/maintain the machine.

Head

Needle

First

Middle

Last

Middle

Last

First

Head

Needle

Needle Point

Needle Bar

Needle Bar

Upper Dead

point

Upper Dead

point

Needle Point

Page 17 Of 17 (주)SUNSTAR SWF C/S Center

Loading...

Loading...