60

PROBLEM TIP or PAGEREMEDYPROBABLE CAUSE

Frequent thread

breaks.

Choose quality thread and

store it away from sunlight

and dust.

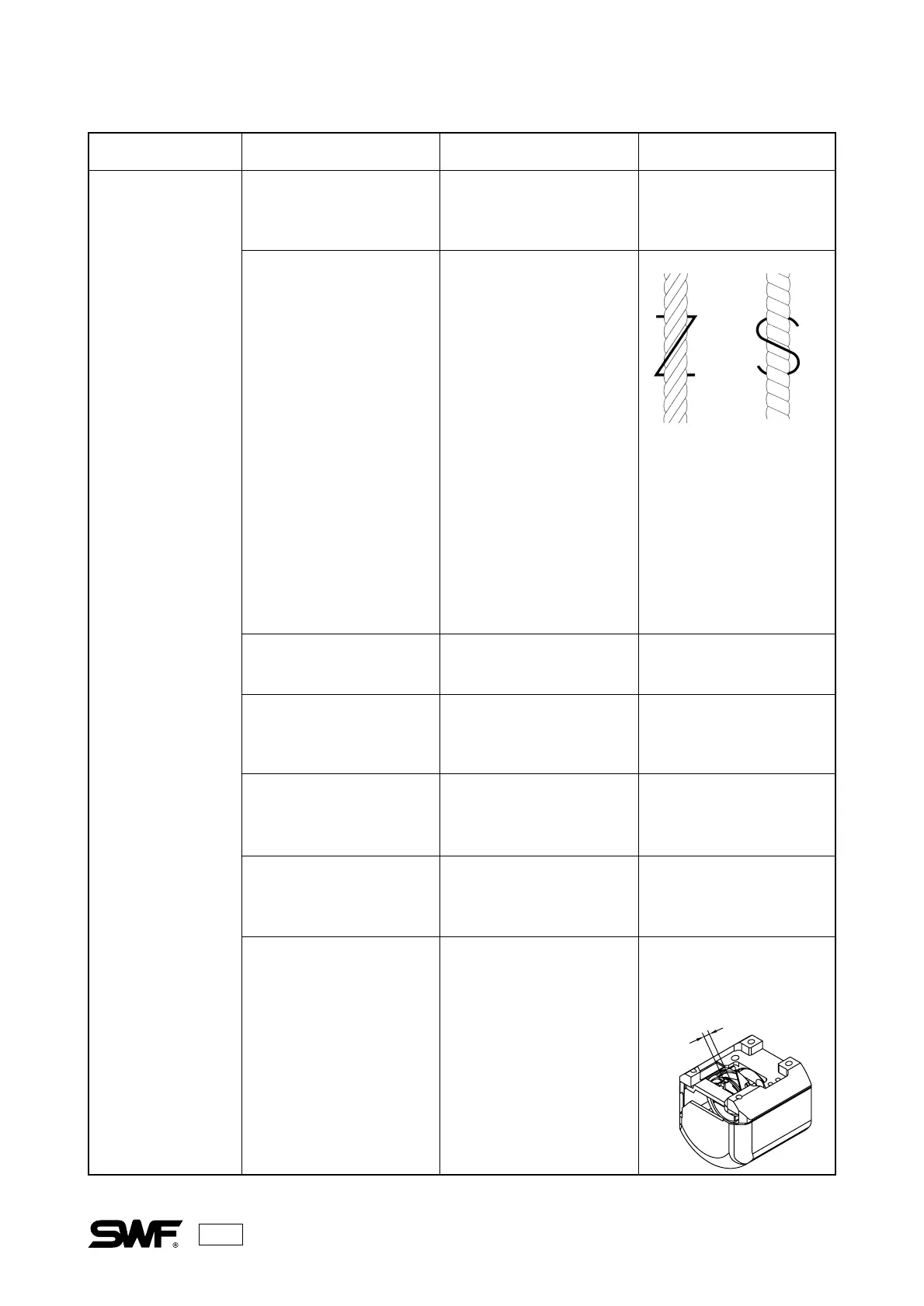

Z-twisted thread(twisted to

the left)

S-twisted thread(twisted to

the right)

Z-twist prevents unraveling

of thread in the

counterclockwise rotation

of the hook

Check rotary hook.

Use good quality thread.

Use Z-twisted thread.

The rotary hook rotates

counterclockwise so Z-

twisted thread prevents the

upper thread from

unraveling.

Adjust tension.

Adjust tension.

Adjust spring tension and

take-up lever.

Use crocus cloth to remove

any nicks and scratches or

replace the damaged part(s).

Adjust the distance.

Poor quality or old thread

(uneven poorly twisted, or

poorly wound.)

Using S-twisted thread.

Upper thread tension is too

tight.

Upper and lower thread not

adjusted correctly in

relationship to each other.

Spring tension is too tight or

take-up lever is not adjusted

correctly.

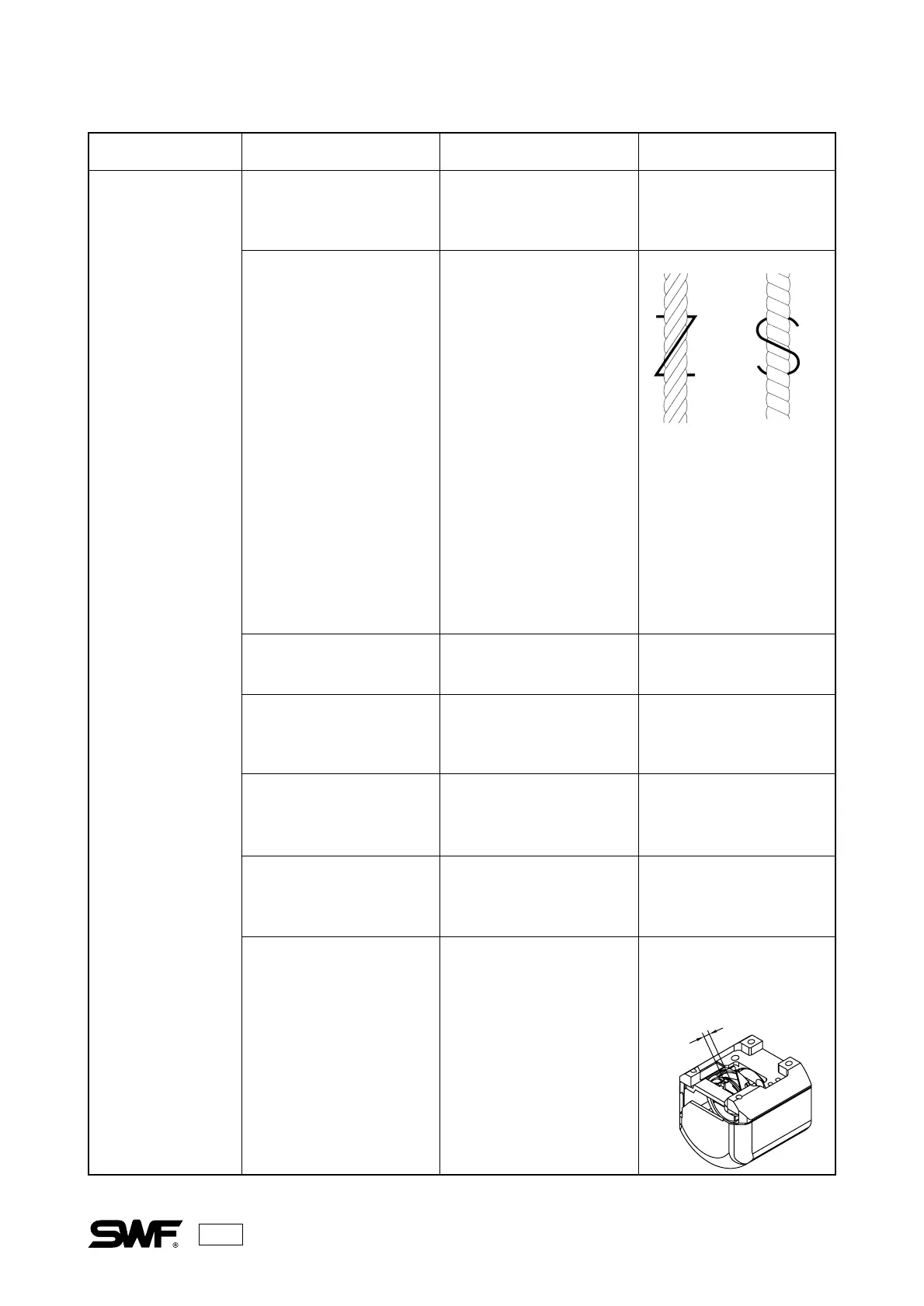

Damaged hook or bobbin

case.

Distance between the hook

and the groove of the

needles is too narrow.

* Correct distance for smooth

passing of upper thread is

0.5~0.7mm.

0.5~0.7mm

Loading...

Loading...