5

L505 DIP-TAPE VISUAL LEVEL INDICATOR

2.0 PREVENTATIVE MAINTENANCE

Periodic inspections are necessary to maintain the proper functionality of the L505 Dip-Tape Visual Level

Indicator. A systematic program of preventative maintenance should be implemented at the time of installation.

If the following instructions are completed routinely, the indicator will provide continuous, reliable protection.

2.1 MAINTENANCE PROCEDURES

2.1.1 Inspect Unit Periodically

Verify that there are no dents or bends in the oat and stem. Should the unit become damaged, obtain a

replacement immediately.

2.1.2 Keep Unit Clean

Periodic cleanings of the oat and stem will ensure the continual, uninterrupted movement of the

mechanism. Always keep the areas around the unit clean and free of any potential interferences. Objects

and debris may cause systematic interruptions and a loss in equipment functionality.

2.2 WHAT TO AVOID

NEVER USE IN SYSTEMS CONTAINING IRON PARTICLES.

The magnet within the oat assembly can attract the particles and become jammed.

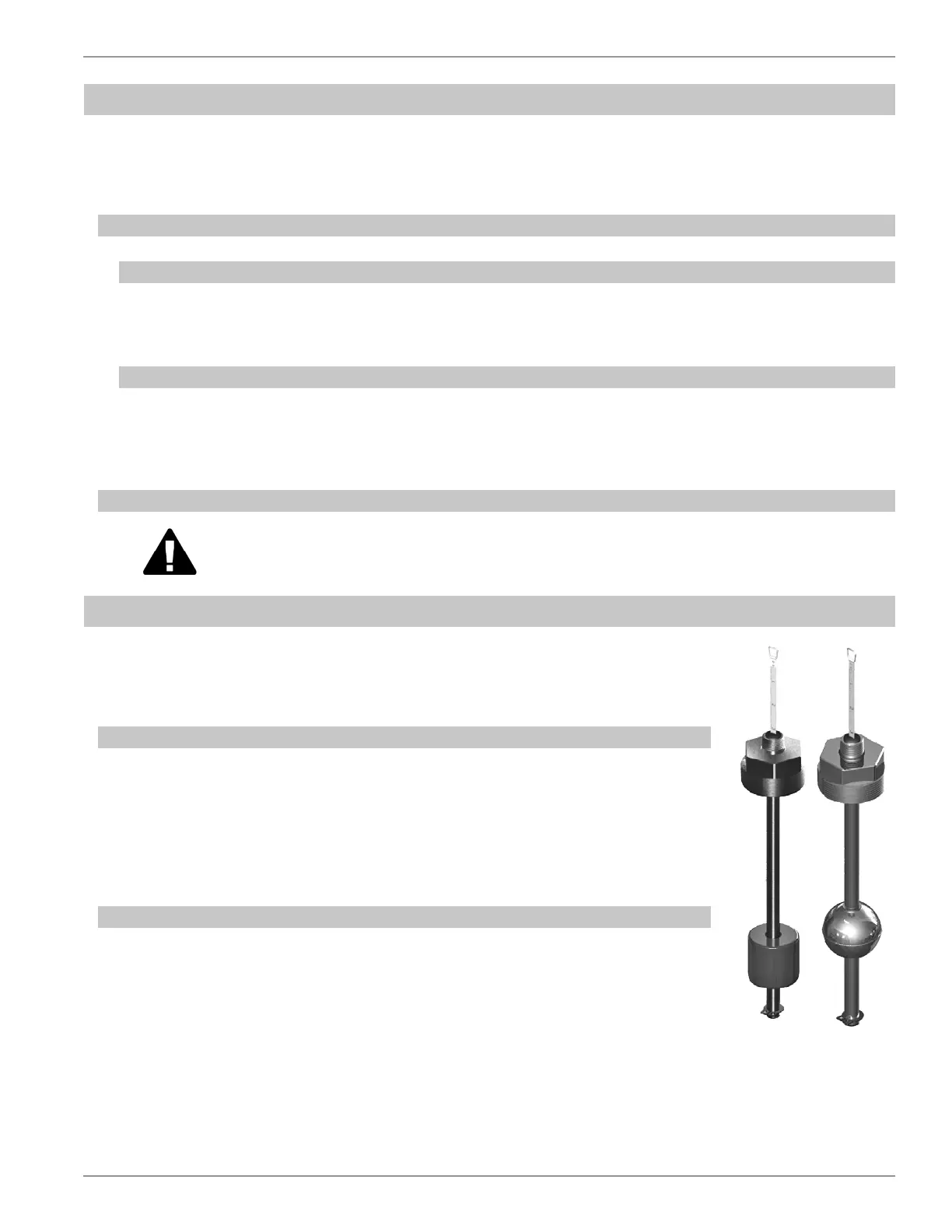

3.0 REFERENCE INFORMATION

This section illustrates an overview of the L505 Dip-Tape Visual Level Indicator, as

well as information on troubleshooting common problems, agency approval listings,

and detailed physical, functional and performance specications.

3.1 DESCRIPTION

The L505 is a simple and economical liquid level indicator designed for quick,

continuous readings in remote and mobile storage tanks. The unit requires no

electricity to operate and provides an accurate visual level indication within

1

⁄

16

”.

Available construction materials include a brass/Buna-N combination and an all

stainless steel option in a variety of threaded mounting sizes. Measuring lengths

range from 6” to 6’ (15.24 cm to 1.8 m) in either customary or metric steel tapes.

3.2 THEORY OF OPERATION

The sliding steel tape magnetically interlocks with the level position of the oat.

Level measurement is obtained by sliding the tape from the stem tube and locating

the calibration mark where the interlock is felt. The oat and stem make contact

with the liquid, but the tape remains separate and clean. When the indicator is not

in use, it is safely sealed within the tube by a protective screw cap.

L505

Stainless Steel

L505

Brass/Buna

Loading...

Loading...