5

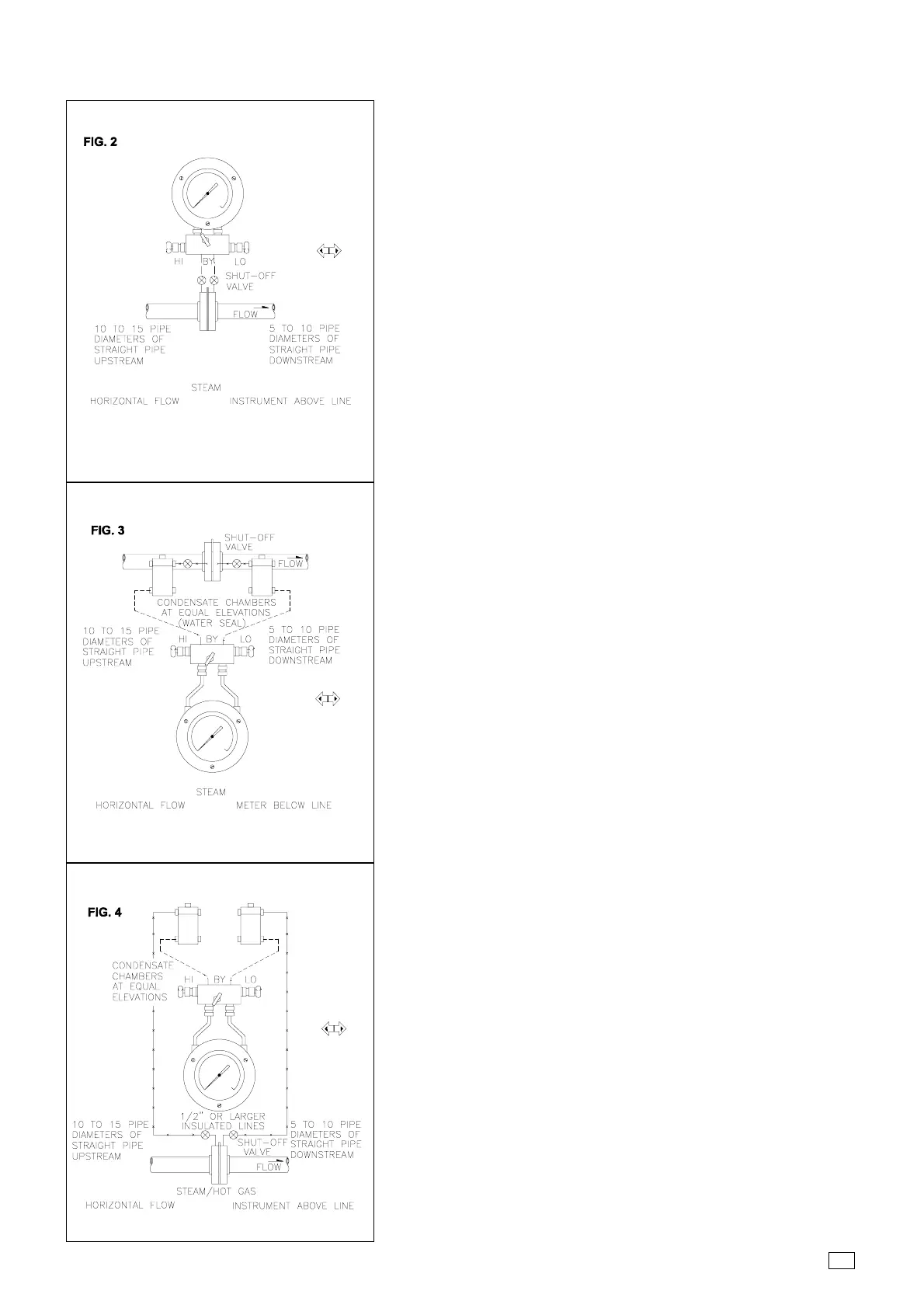

FOR STEAM SERVICE (FIG.2)

START UP

Recommended when Instrument located above primary element

and where self draining is possible& for operating temperature

upto 200°F

1. Whatever the location of the meter body, make all primary element

taps at or near top of pipe

2. Close block valves & vent valves (if used). Open bypass valve

and shut-off valves.

3. Slowly and simultaneously open block valves, then close shut-off

valves.

4. Slowly and simultaneously open shut-off valves.

5. Close bypass valve for D/P reading.

If D.P.Gauge to be located below the primary element, see fig 3.

For higher temperatures, see Fig. 4.

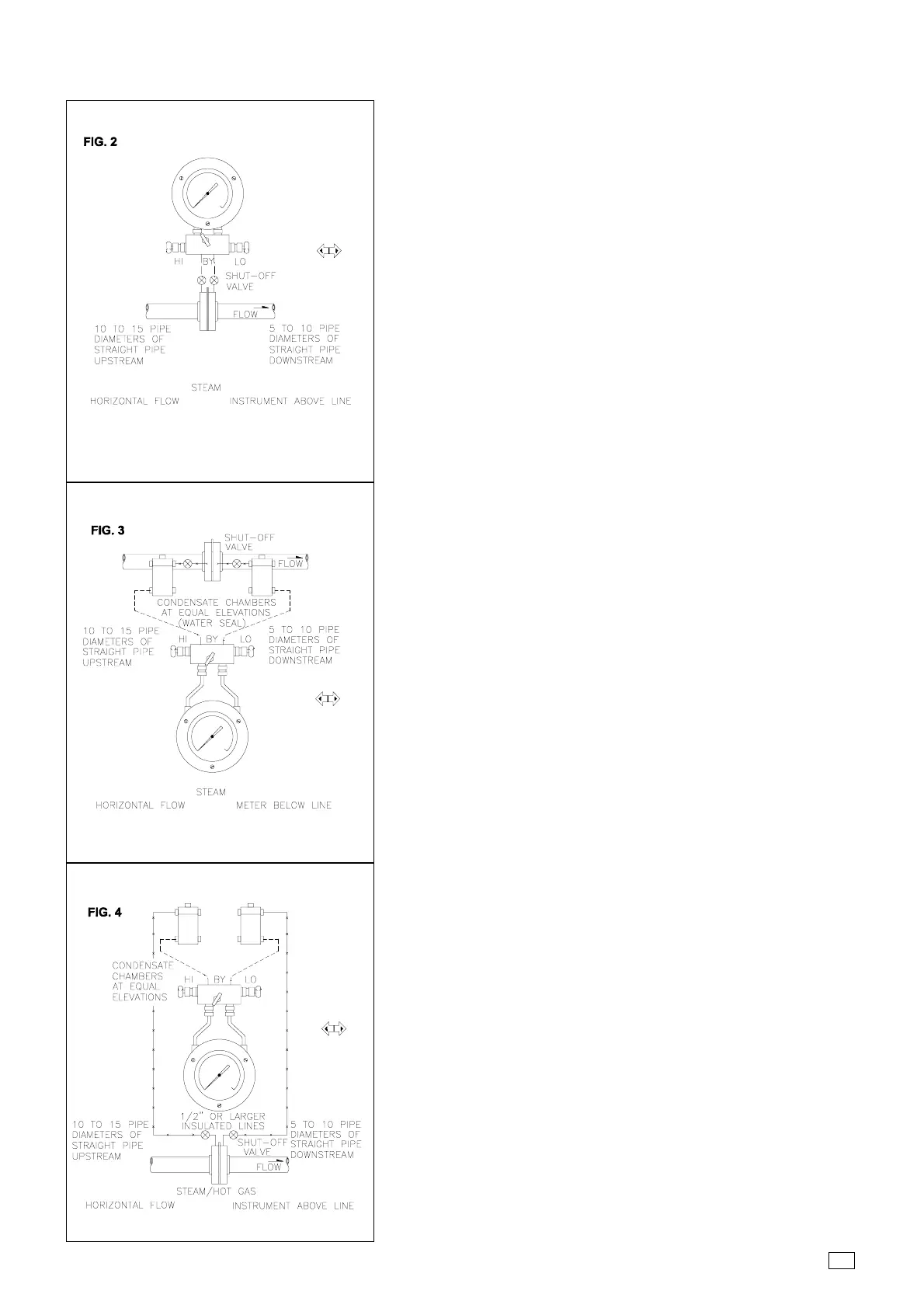

FOR STEAM SERVICE (FIG.3)

START-UP

Reccomended when Instrument located below primary element

and for operating temperature upto 200°F

NOTE

To prevent overheating during instrument blow-down, monitor the

temperature by placing your hand on the pipe between the D.P.gauge

and the vent valves.

1. Close shut-off valves and vent valves (if used). Open by pass

valve and block valves.

2. Remove side and fill plugs from condensate chambers.

3. Fill piping and instrument chambers with water by pouring into

fill port in both condensate chambers to the level of the side

plugs.Instrument chambers and piping must be free of bubbles.

When instrument and piping are completely full, pointer will

rest at zero.

4. Install plugs in ports of condensate chambers.

5. Slowly and simultaneously open shut-off valves then close.

6. Check for leaks as explained in clause I.

7. Slowly and simultaneously open shut-off valves.

8. Close bypass valve for D/P reading.

FOR STEAM or HOT GASES (FIG.4)

START-UP

Recommended when Instrument located above primary element

and for operating temperature greater than 200°F.

See clause “ H ” and then follow steps in Fig.3.

K D.P.GAUGE PIPING DIAGRAMS

Loading...

Loading...