D500-19-00 2 I56-762-01

Compatible Two-wire System Sensor Smoke Detectors for Use with M502M with Zone Identifier A:

Detector Compatability Detector Base Base Max

Model ID Type Model Identifier Detectors

1451 A Ionization B401/B A 20

2451 A Photoelectric B401/B A 20

2451TH A Photoelectric with Thermal B401/B A 20

1400 A Ionization N/A — 20

2400 A Photoelectric N/A — 20

2400TH A Photoelectric with Thermal N/A — 20

1100 A Ionization N/A — 20

1151 A Ionization B110LP/B401 A 20

2100 A Photoelectric N/A — 20

2100T A Photoelectric with Thermal N/A — 20

2151 A Photoelectric B110LP/B401 A 20

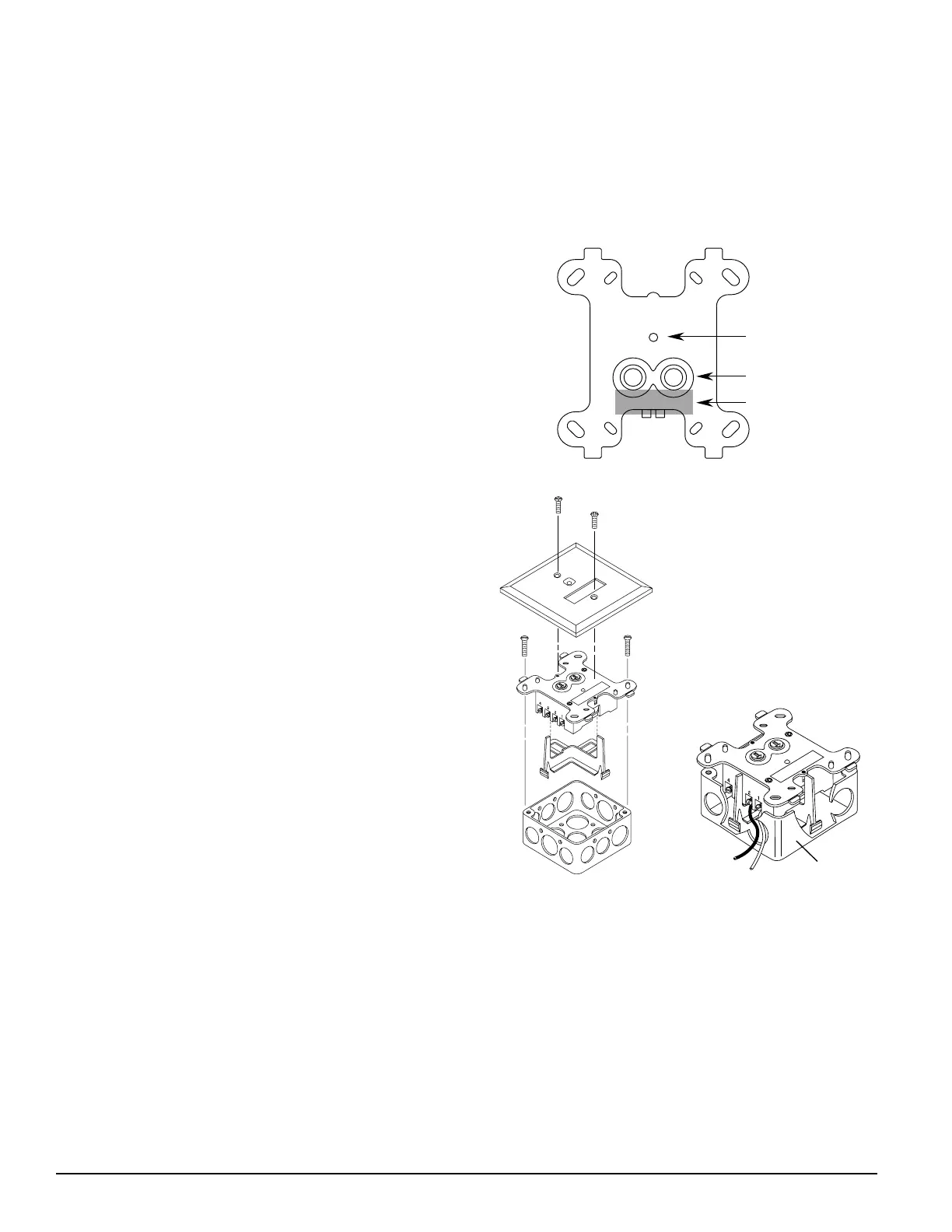

Figure 1. Module controls and indicators:

ISOLATED

QUADRANT

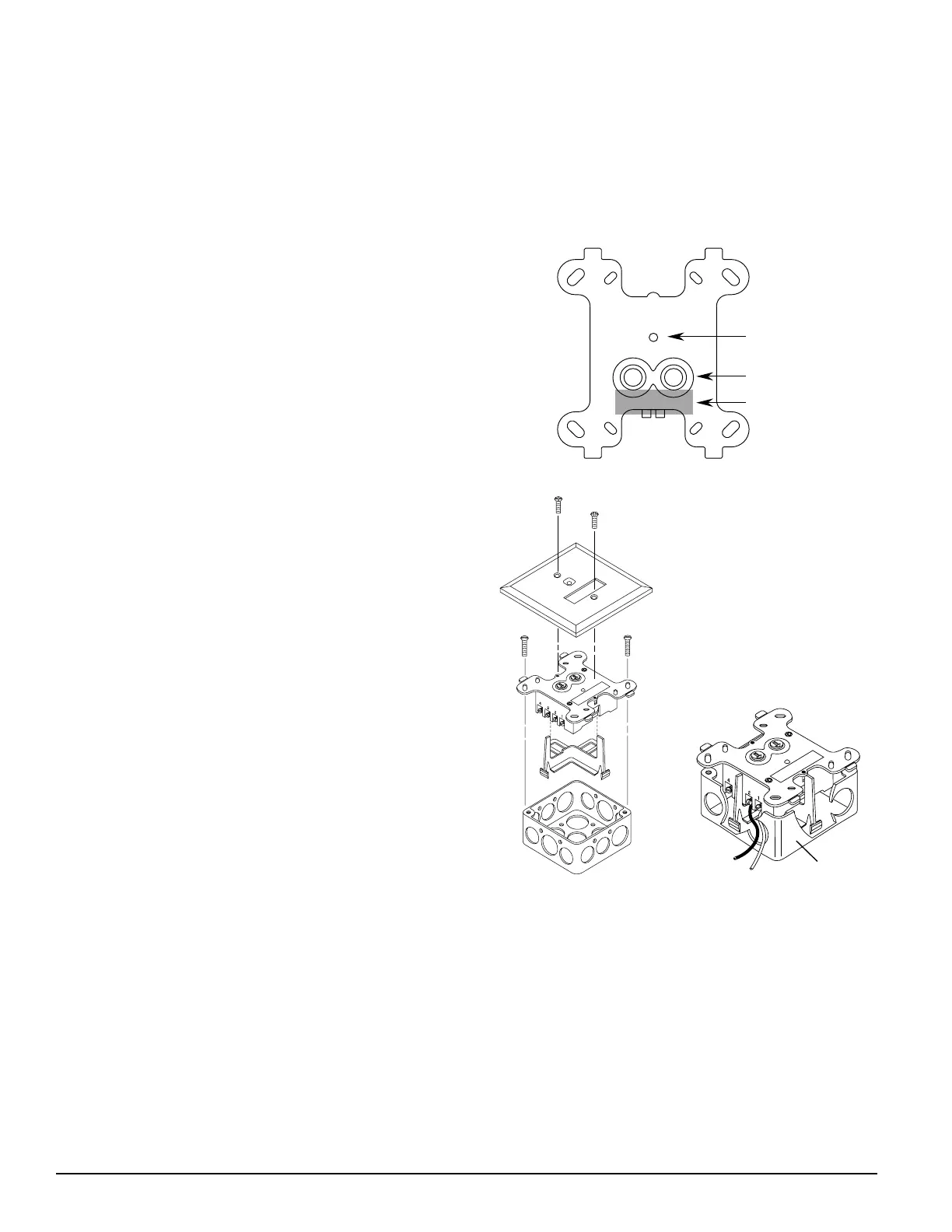

Figure 2B:

A78-2611-00

the module’s electronics and connections to the control

panel (see Figure 1).

Compatibility Requirements

To insure proper operation, this module shall be connected

to compatible intelligent control panels only.Conventional

two-wire smoke detectors must be UL compatible with the

interface module. A list of compatible two-wire convention-

al detectors is below.

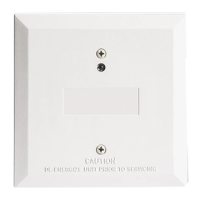

Package Contents

The interface module includes the following items:

(1) Two-wire interface module

(1) 3.9K ohm end-of-line resistor (A2143-10)

(1) Off-white cover plate

(1) Screw pack for cover plate

Mounting

The M502M Interface Module mounts directly to 4 inch

square electrical boxes as shown in Figure 2. The box must

have a minimum depth of 2-1/8 inches.

Wiring

NOTE: All wiring must conform to applicable local codes,

ordinances and regulations. When using control

modules in nonpower limited applications, the Sys-

tem Sensor CB500 Module Barrier must be used to

meet UL requirements for the separation of power-

limited and nonpower-limited terminals and wir-

ing. The barrier must be inserted in a 4"x4"x2

1

/

8

"

junction box, and the control module must be

placed into the barrier and attached to the junction

box (Figure 2A). The power-limited wiring must be

placed into the isolated quadrant of the module

barrier (Figure 2B).

1. Install module wiring in accordance with the job draw-

ings and appropriate wiring diagrams (Figures 3 – 5).

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer),

as shown in Figure 2A.

Testing

The M502M Interface Module can be tested with a test

magnet available from System Sensor (M02-04-01- see Fig-

ure 1). The magnet test checks the module’s electronics

and connections to the control panel. Interfaced two-wire

detectors must be tested independently. Test two-wire de-

tectors per manufacturer’s installation instructions.

STATUS LED

ROTARY DECADE

ADDRESS SWITCHES

MAGNET TEST

POSITION

27

0

1

3

4

5

6

8

9

27

0

1

3

4

5

6

8

9

A78-2318-00

A78-2610-00

Figure 2A. Mounting module with barrier:

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...