Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 9

PROCESS SELECTION (Cont.)

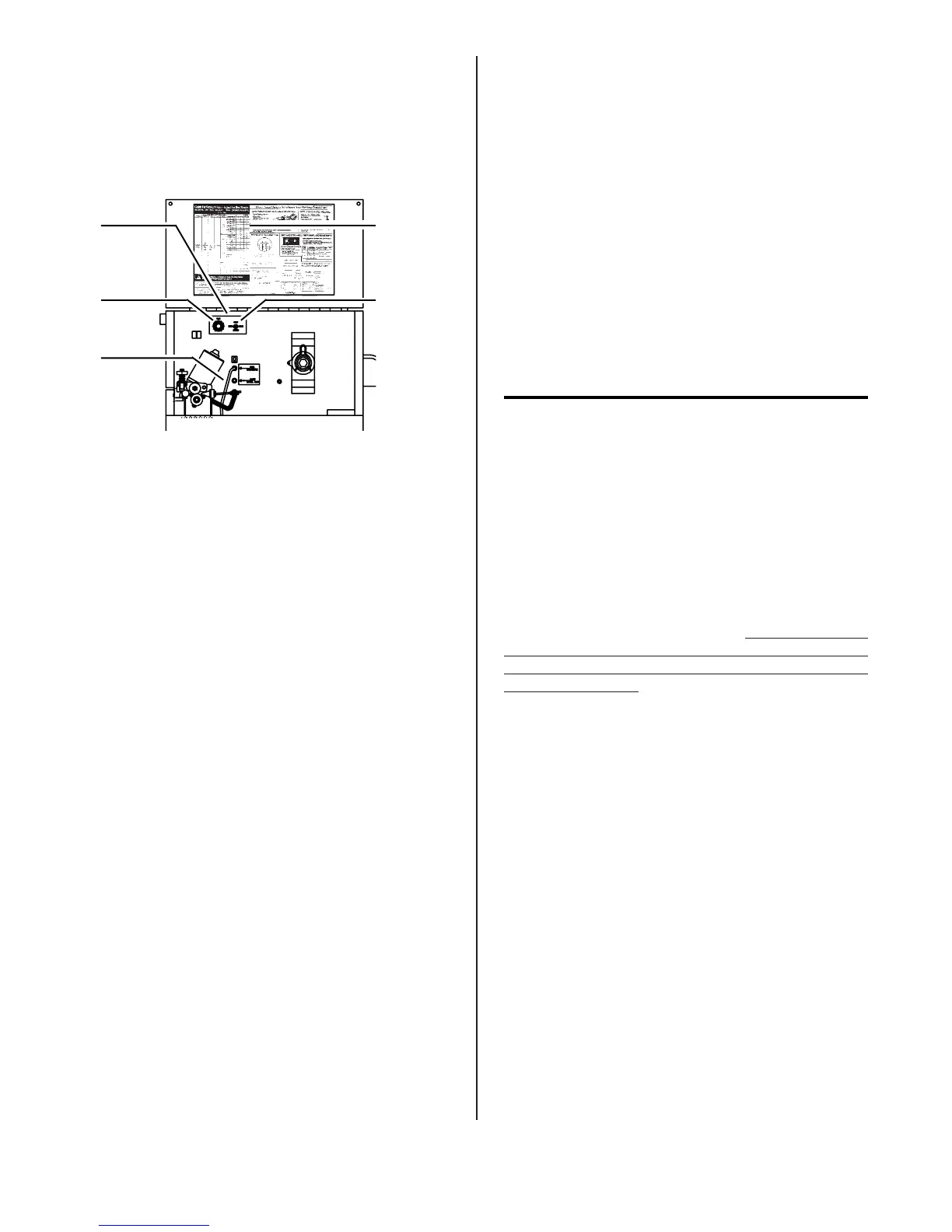

The following controls are lo-

cated on the inside of the machine,

in the wire feed compartment.

E. *FUNCTION SWITCH

Controls mode of operation of

welding machine. "CONT. WELD"

position is for normal, con-

tinuous welding operation.

"SPOT" position puts the spot

timer in the circuit for auto-

matic MIG Consumable Spot Weld-

ing. "STITCH" position is used

for stitch welding on very

light material. When in

"STITCH" position, the length

of time the welder is "ON" and

feeding wire is controlled by

the Spot Timer. The lower the

Spot Timer setting, the faster

the welder cycles on and off.

A.

*OPTIONAL

SSTP-2

MODULE

B.

*SPOT

TIMER

C.

SELECTOR

HOSE

D.

PARAMETER

CHART

E.

*FUNCTION

SWITCH

WELDING

Optimum control settings will

vary according to the thickness of

the metal, the type of joint,

operator preference, etc. Best

results can be obtained through

experience with the welding ma-

chine or by making trial welds.

Select some sample material of the

same type and thickness as the

material to be welded. Refer to the

Parameter Chart located on the

access door to the wire feed

compartment. Set the welding

controls for optimum results using

the sample material thickness and

wire size being used as a starting

point, weld until experience is

gained using the unit.

CONTINUOUS WELDING ON STEEL

1. Trim the electrode wire to

leave approximately 1/4 inch

stickout beyond the end of the

contact tip and install the

welding nozzle. The contact tip

should be flush or stick out up

to 1/16 inch beyond the end of

the nozzle.

A. *OPTIONAL SSTP-2 MODULE

With the optional Spot/Stitch

Module installed MIG Spot weld-

ing and Stitch welding can be

performed.

B. *SPOT/STITCH TIMER

After the torch trigger is

actuated, the timer allows the

wire to feed and the gas and

power to flow for the time

selected. The Function Switch

must be set in the "SPOT"

position (or the "STITCH" posi-

tion for stitch welding).

C. SELECTOR HOSE

Attaches to MIG position for

Standard welding through the

MIG torch assembly or to MHG7

position for Aluminum welding

with the spool gun option.

D. PARAMETER CHART

This chart is a guide for basic

setup parameters.

(continued on following page)

FIGURE 9. WIRE FEED COMPARTMENT

Loading...

Loading...