20 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

3. Move the selector hose to the

"MHG7 SPOOL GUN" fitting and

tighten.

4. Install the thread cap (removed

in step 1) on the "MIG STANDARD"

fitting to prevent dirt and

contaminants from entering the

unused gas line.

5. Unplug the wire feed motor plug

from the function receptacle.

6. Plug the MHG7 spool gun control

cable plug into the welder

function receptacle.

7. Remove the torch selector cable

from the welder positive (+)

weld connector.

8. Plug the MHG7 gun cable fitting

into the welder positive (+)

weld connector.

NOTE

Make sure the gas regula-

tor and welder gas hose

are connected to a cylin-

der of the proper shield-

ing gas - 100% argon for

aluminum welding; 75% ar-

gon + 25% CO2 for steel

welding. 98% argon + 2% O2

is recommended for stain-

less steel welding.

9. Follow the operating instruc-

tions in the MHG7 manual(Form

WC5120).

10.To change back to standard MIG

operation, reverse the proce-

dure.

CONNECTING TIGIT2 OR MHG7

SPOOL GUN

CHANGING FROM STANDARD MIG OPERATION

TO TIGIT2 OPERATION

1. Unplug the wire feed motor plug

from the function receptacle.

2. Unplug the torch selector cable

and the work (ground) cable

from the welder front panel.

3. Plug the TIGIT2 torch power

cable into the negative (-)

weld connector and plug the

work (ground) cable into the

positive (+) weld connector.

This provides straight polar-

ity current as required for TIG

welding.

4. Plug the TIGIT2 torch switch

cord into the welder function

receptacle.

5. Attach the TIGIT2 torch gas

hose directly to the gas regu-

lator.

NOTE

Pure argon is the shield-

ing gas to be used for TIG

welding.

6. Follow the operating instruc-

tions in the TIGIT2 manual

(Form WC5227).

7. To change back to MIG opera-

tion, reverse the procedure.

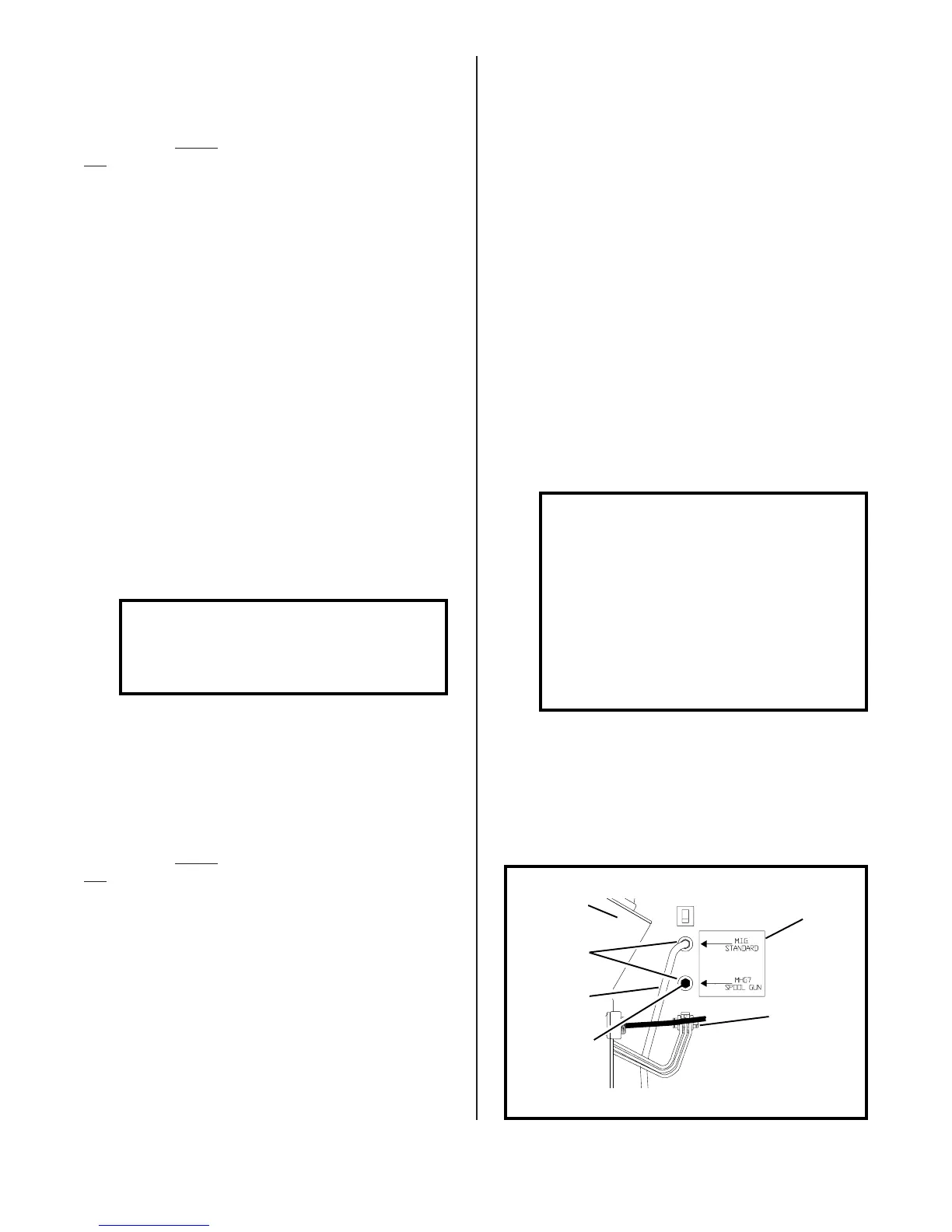

CHANGING

FROM STANDARD MIG OPERATION

TO MHG7 SPOOL GUN OPERATION

All current model MIG machines

are equipped with bulkhead gas

fittings for quick and easy

changeover from standard MIG op-

eration to spool gun operation.

1. Remove the thread cap from the

"MHG7 SPOOL GUN" fitting.

2. Unscrew the selector hose from

the "MIG STANDARD" fitting.

FIG. 18. BULKHEAD CONNECTIONS

LABEL

WIRE FEED

MOTOR

BULKHEAD

FITTINGS

SELECTOR

HOSE

THREAD

CAP

WIRE FEED

MOTOR

PLUG

(PLUGGED

INTO

FUNCTION

RECEPTACLE)

Loading...

Loading...