Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380 21

The MIG torch liner provided

with the MP140 is designed for wire

diameters from .035 thru .045. If

smaller wire diameters are to be

fed and or there is a problem (i.e.

clog, kink, etc.), a liner change

is required.

Following is a step by step

guide to aid in liner removal and

installation.

NOTE

When removing the welding wire

from the MIG torch, care should

be taken to avoid the wire from

uncoiling from the wire spool.

REMOVING OLD LINER

1. Remove torch assembly from the

welding machine.

2. Place torch assembly on a flat

surface, making sure torch is

laying straight as possible.

3. Remove nozzle, bushing insula-

tor, contact tip and gas dif-

fuser from the front end of the

torch assembly.

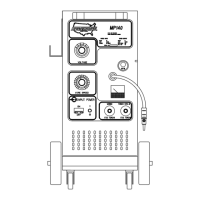

4. Loosen set screw located on the

connector end of the torch

assembly (see fig. 20).

5. Grip the liner and gas seal

firmly, then pull. The liner

should easily slide from the

torch assembly.

INSTALLING NEW LINER

1. Remove the new liner from the

package.

2. Uncoil liner and lay the liner

parallel next to the MIG torch

assembly.

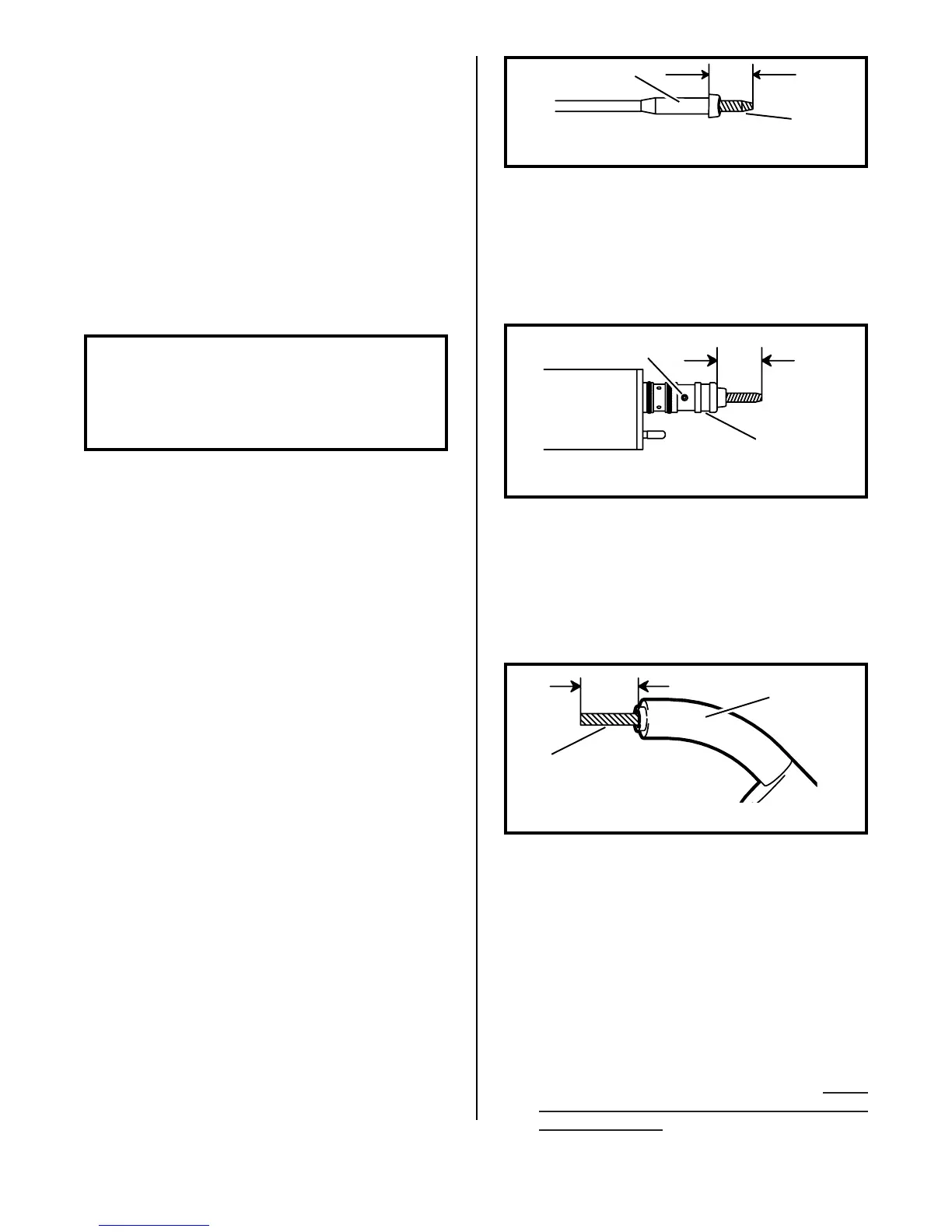

3. Adjust the liner stickout length

to 3/4" as shown in fig. 19.

3/4"

LINER

STICKOUT

GAS SEAL

SET SCREW

3/4"

CONNECTOR

PLUG

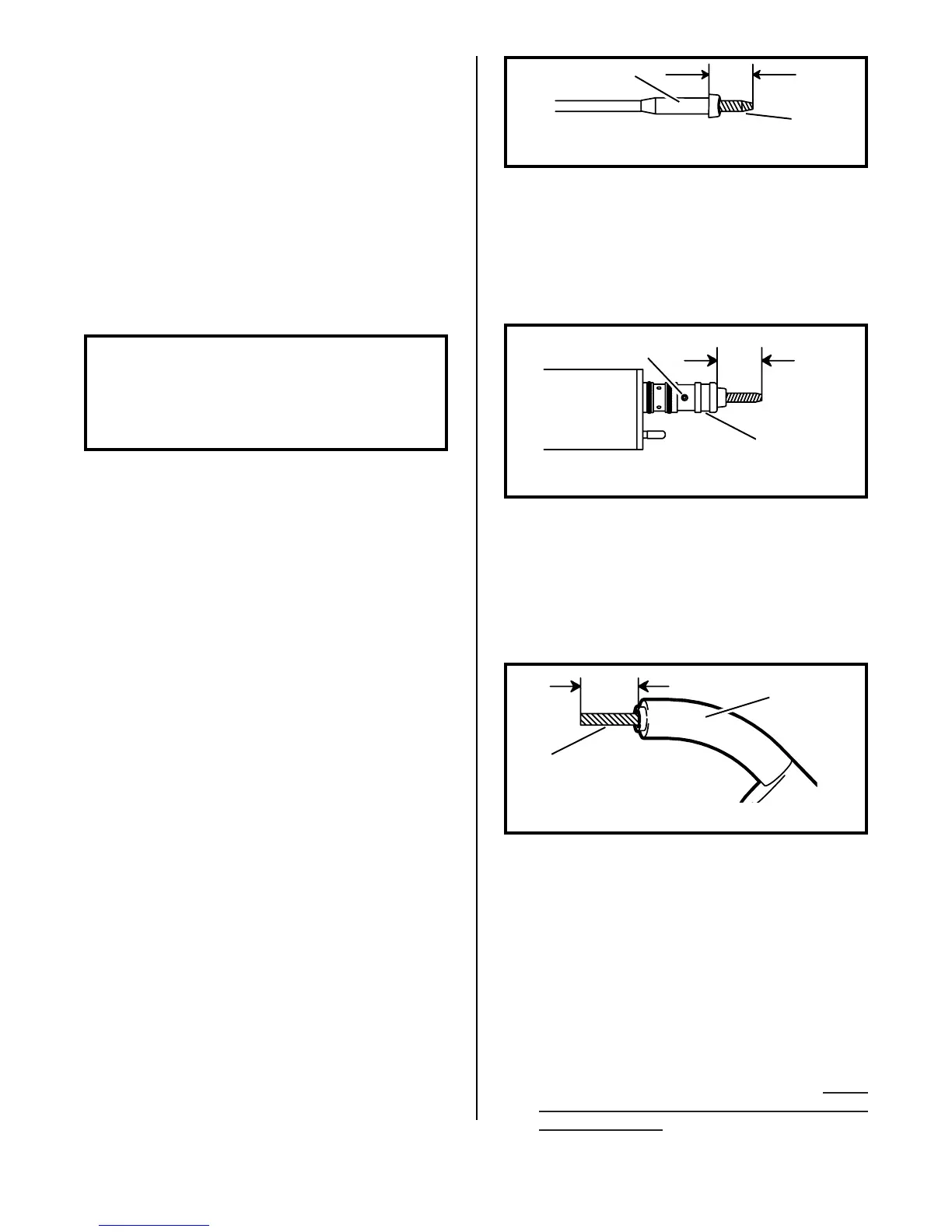

1 1/4+"

PROTRUDING

LINER

NECK

ASSEMBLY

4. Install the new liner into the

MIG torch assembly, until gas

seal seats flush with the con-

nector plug.

5. Tighten set screw. (Do not

overtighten), refer to fig. 20.

6. Following the diagram in fig.

21, measure out 1 1/4"+ from the

neck assembly and cut off the

protruding liner.

7. Debur the cutoff end of the

liner to insure unobstructed

wire feed.

8. Install the gas diffuser and

contact tip of proper wire

size, tighten with a wrench.

9. Install the bushing insulator

onto the gas diffuser. Spray

the "O" rings with anti-spatter

compound for lubrication.

10.Install the TWIST-ON adjust-

able nozzle and twist the nozzle

during the installation. Turn

to Page 6 for correct nozzle

adjustment.

FIGURE 21. TORCH FRONT END

FIGURE 20. TORCH CONNECTOR END

FIGURE 19. LINER STICKOUT

M.I.G. TORCH LINER

INSTALLATION

(steel only)

Loading...

Loading...