12 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380

MIG SPOT WELDING ON STEEL

(Continued)

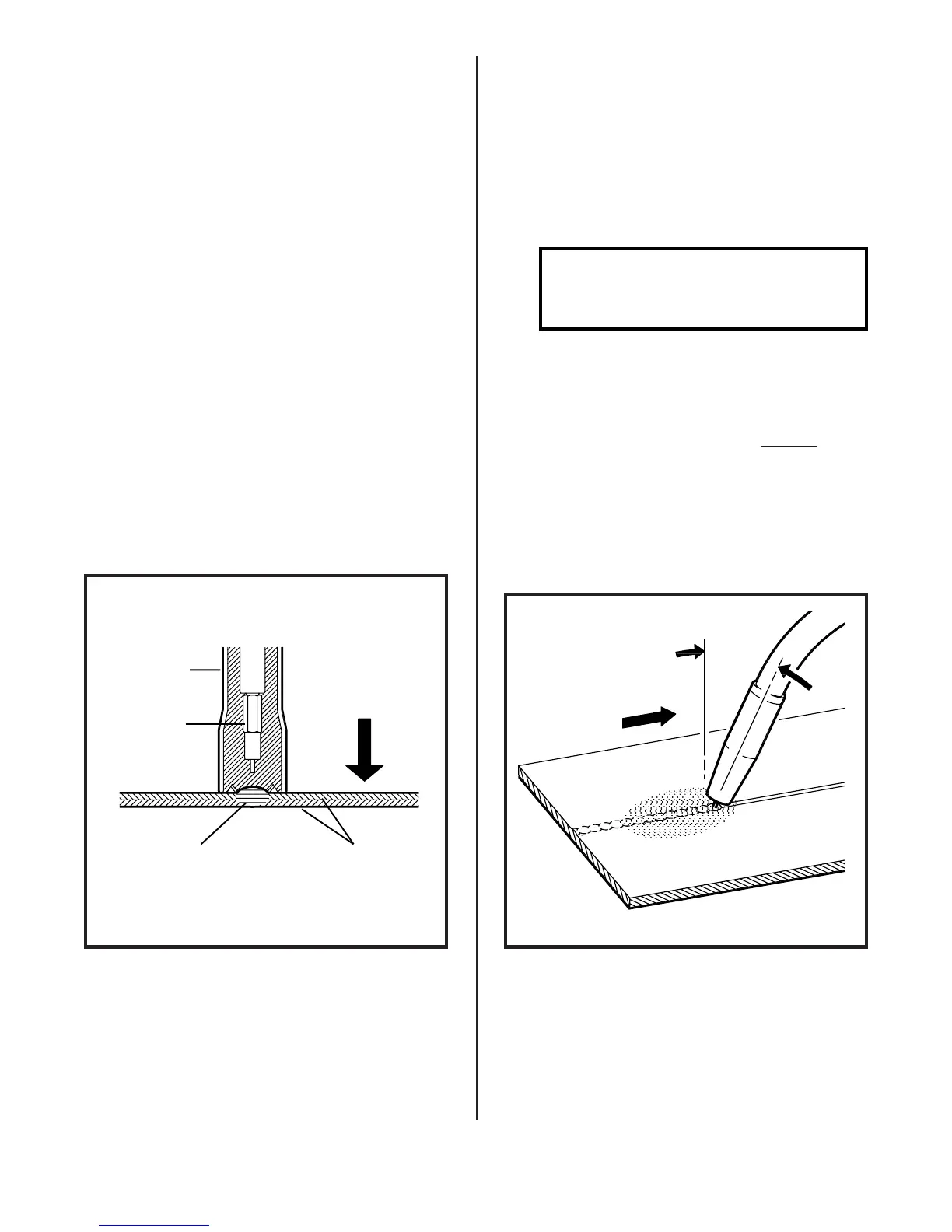

3. Locate the torch on the area to

be welded and press the nozzle

firmly against the work to hold

the metals in place.

4. Guard the eyes against stray

arc flash. A weldor’s helmet is

not necessary when spot weld-

ing. However,

extreme caution

must be taken to avoid looking

at the arc.

5. Actuate the torch trigger to

start the weld sequence. When

the timer switches off the weld

current, release the trigger

but maintain firm contact be-

tween the torch and work. Wait

one second for the weld puddle

to solidify, then move to the

next spot position. If the wire

freezes in the puddle, a quick

squeeze of the torch trigger

will melt it off.

6. To ascertain a good spot weld,

look at the back side of the

welded material. A small melt-

through of approximately 1/16

inch diameter is ideal.

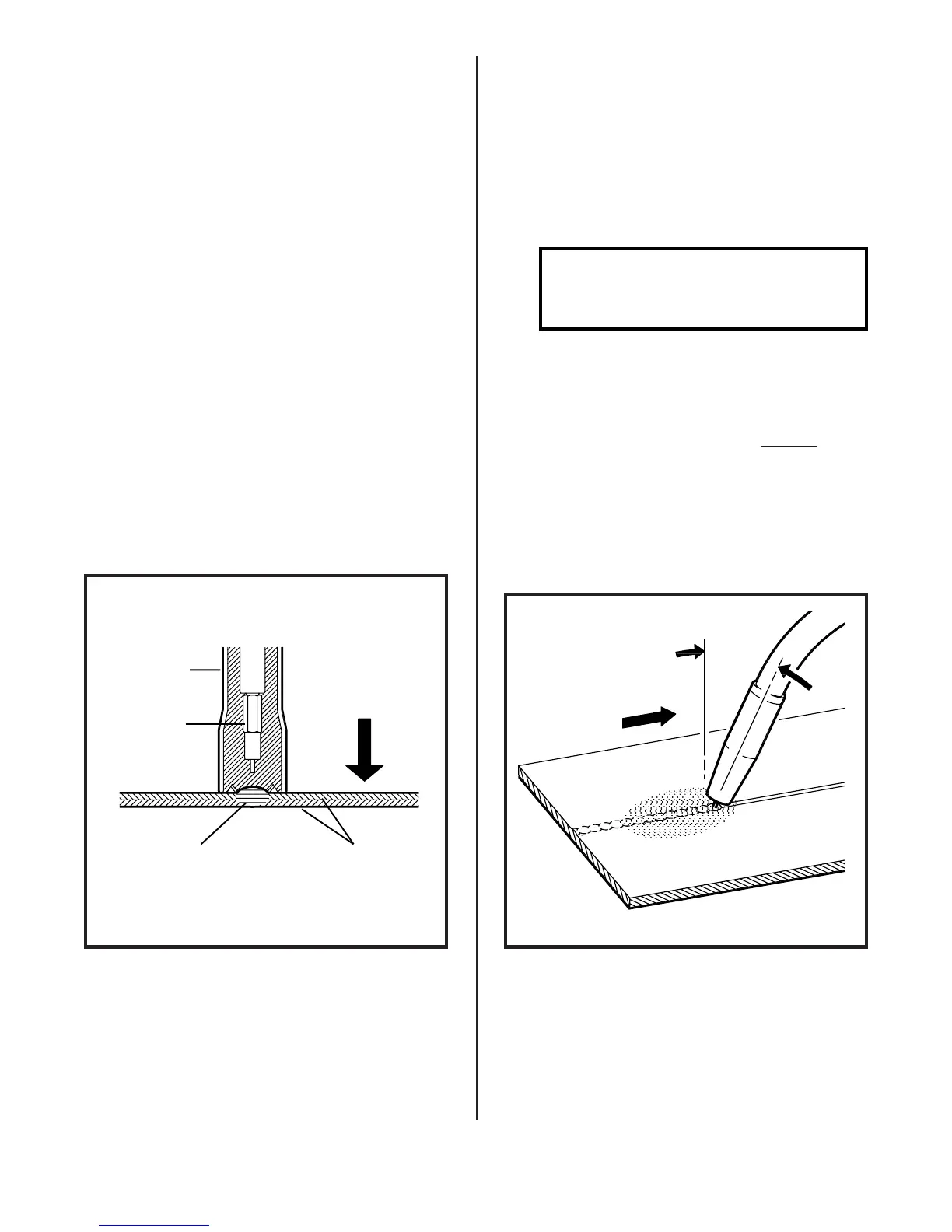

STITCH WELDING ON STEEL

(OPTIONAL)

NOTE

Stitch Welding is used for

very light material.

1. Set Function Switch to "STITCH".

2. Adjust the TIME control to set

the time the welder is "on" and

feeding wire. The lower the

setting, the shorter the "on"

time and the faster the unit

cycles on and off.

3. Weld using "Continuous Weld-

ing" torch position and direc-

tion of travel.

DIRECTION

OF TRAVEL

WORK

SHIELDING GAS

30 DEGREES

FIGURE 15. STITCH WELDING

WORK

SPOTWELD

SPOTWELD

NOZZLE

CONTACT

TIP

PRESS NOZZLE

FIRMLY

AGAINST WORK

FIGURE 14. MIG SPOT WELDING

Loading...

Loading...