2

9. Check run-out on bowl shaft extensions by placing dial indi-

cator toward the end of the shaft and turning slowly making

certain the shaft stays to one side of the upper most bowl

bearing. Total Indicating Run-Out should not exceed .005”.

10. Check and record the total bowl lateral or end play. If a

solid shaft motor is used, this information will be required for

flanged coupling assembly.

A5: INSTALLATION INSTRUCTIONS

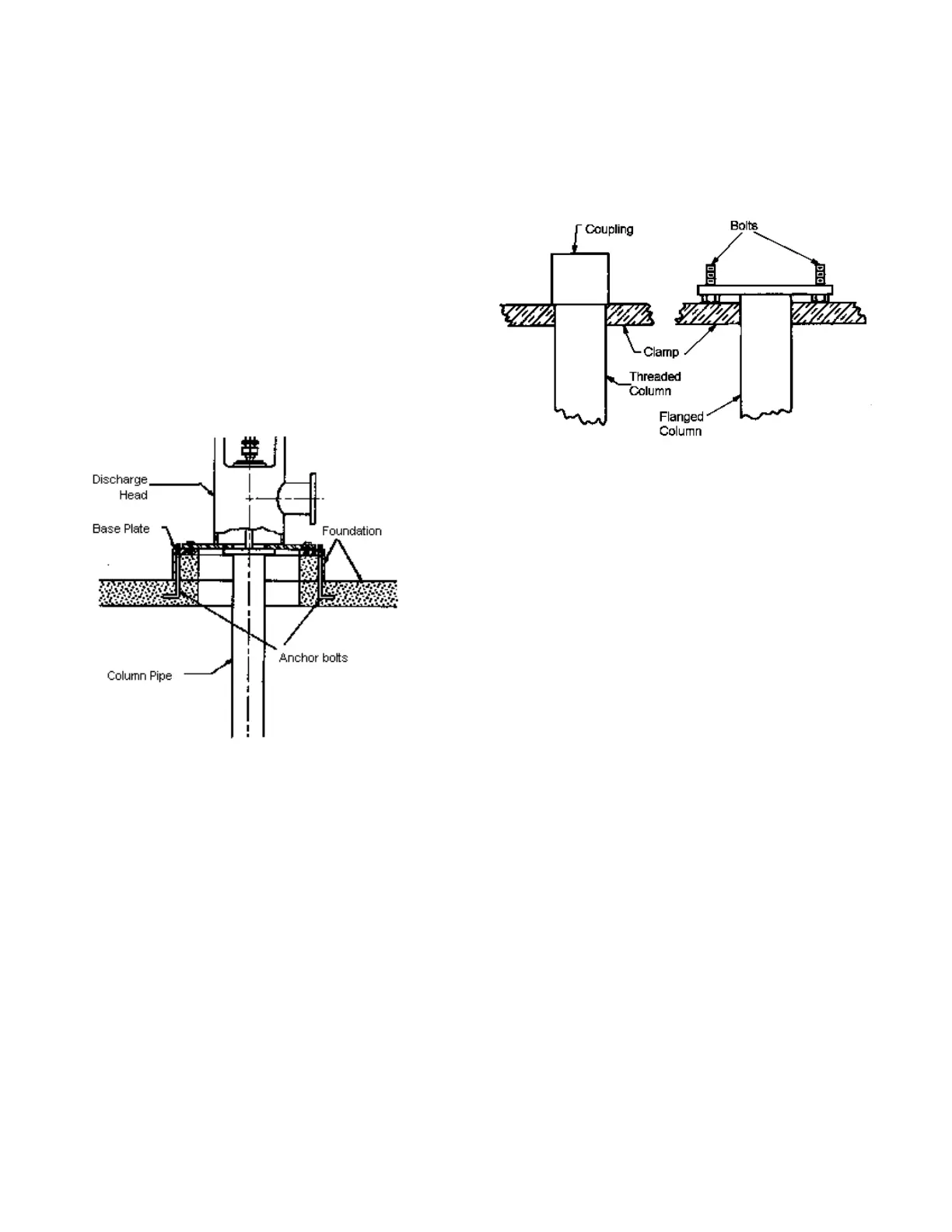

A5.1: BASE PLATE OR FOUNDATION PLATE

(IF SUPPLIED)

1. Place foundation plate over anchor bolts and allow to rest on

foundation. Check to make sure foundation plate is level, use

wedges or shim stock if necessary. Full contact with founda-

tion is important for vibration free operation.

2. If the final elevation of the plate is critical, this should be

checked at this time.

3. Attach hex nuts to anchor bolts and turn until snug against

foundation plate.

4. The foundation plate serves as a good surface for the dis-

charge head. See Figure A5.1.

A5.2: PUMP BOWL

1. Place the two beams on the foundation plate or foundation

opening.

2. Secure the proper clamp to the upper end of the bowl beneath

a convenient shoulder. If only one sling is used, attach the

sling to the clamps far enough out on the ears to allow for easy

removal after setting the unit down on the beams.

3. Hoist the bowl to a vertical position using the derrick. If the

bowl is equipped with a strainer, do not drag the strainer

across the floor.

4. If there is any auxiliary piping to the bowl bearing or the

thermo-wells, make certain the bowl portion of the piping is

attached to the bowl at this time.

5. Center the bowl over installation opening then carefully lower

until the clamp ears are resting squarely on the beams. Then

remove the sling.

6. Clean the following items: shaft threads, discharge threads,

flange face (if applicable), threads and face of oil tubing (if

applicable). Lightly oil the shaft threads and screw the cou-

pling on half way. Place a rag over the coupling to prevent

entrance of foreign matter during the next step in assembly.

A5.3: COLUMN OPEN LINESHAFT

Refer to the installation plan or the overall dimension sheet

of the submittal to determine correct sequence for installation of

column lengths.

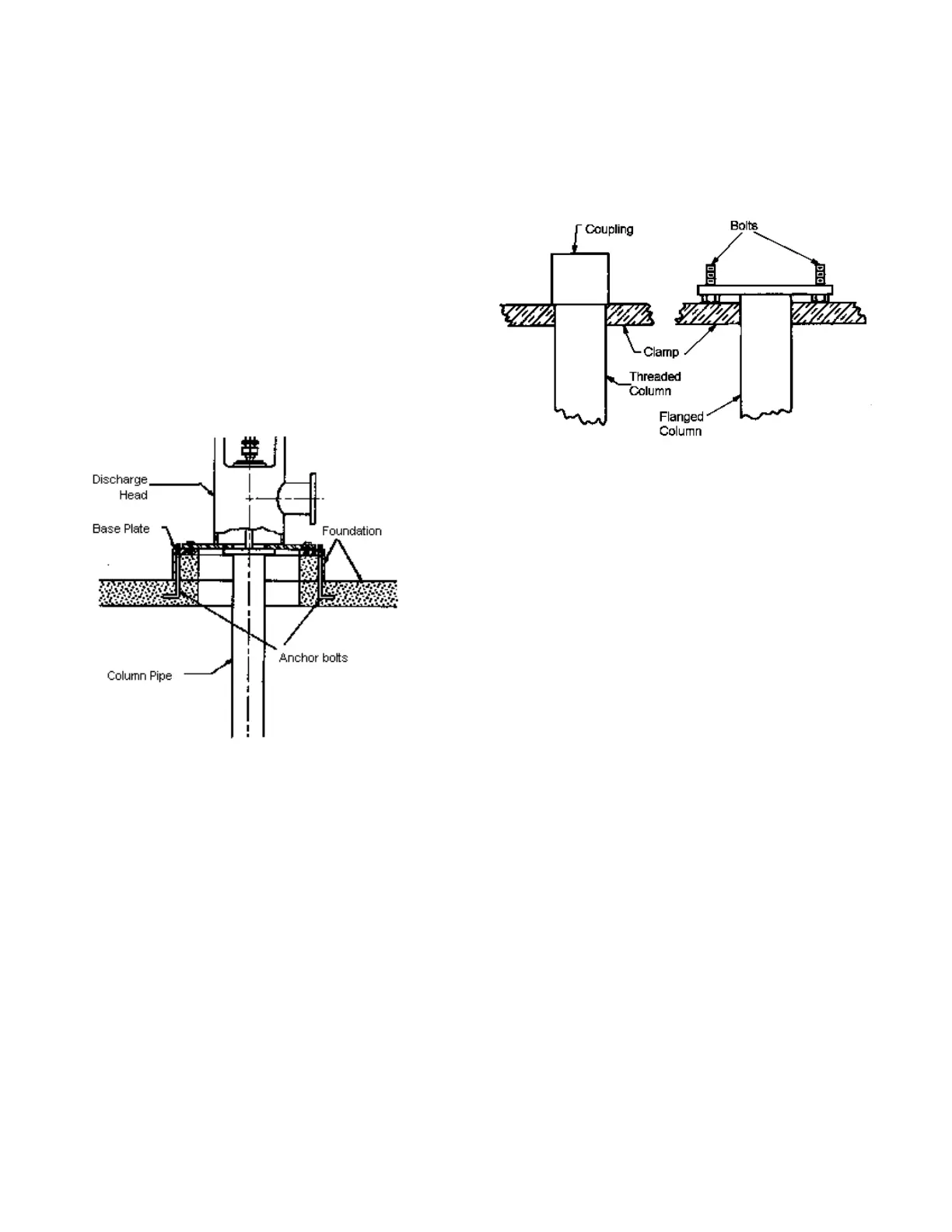

1. Secure pipe clamp immediately beneath column coupling.

If column is flanged, insert bolts and secure clamp below

bottom of flange. Clamp should keep bolts in position. See

Figure A5.3.1.

2. Slide the lineshaft into bottom of column pipe and allow it to

extend approximately 15” below the bottom end of the pipe.

Make certain the sleeve area of the lineshaft (if applicable)

is toward the top of the pipe. Tie a series of half hitches to

the column pipe and lineshaft with

3

⁄

4

” rope. (Tie the rope to

a chain pipe vise on the lineshaft, if needed.) Attach the sling

to the clamp ears as described under Section A5.2, Step 2.

3. Hoist column and lineshaft to a vertical position with the der-

rick. Do not drag shaft across the floor. Before centering col-

umn over bowl, tap the side of column to remove any loose

matter.

4. Position the column and lineshaft over the bowl. Align the

lineshaft and remove the rag from the bowlshaft coupling.

Lightly oil the threads. Lower until the lineshaft contacts cou-

pling. Remove the rope. Hold coupling and turn the lineshaft

(left hand threads) until the shaft ends butt up. Place one

pipe wrench on the coupling and one on the lineshaft. Tighten

securely. Remove the wrench marks form the shaft and cou-

pling with a flat file and emery cloth.

5.a If bowl to column connection is threaded, apply thread

compound to the pipe threads. Attach chain tongs to bowl

and to column for support. Lower the column pipe, and at

the same time, turn the pipe until it seats against the mating

shoulder on the bowl. Tighten pipe into bowl securely.

5.b If bowl to column connection is flanged, spread a thin,

even film of gasket compound on the bowl discharge flange.

Lower pipe and align studs in the bowl with the holes in the

flange. Seat the column flange against bowl flange. Install

and tighten hex nuts evenly.

6. Hoist assembly enough to remove the clamp on the bowl

assembly.

7. If there is any auxiliary piping to bowl bearing or thermo-well

being used, that portion that attaches to the column section

should now be installed. Also, if the bowl and column are

coated with any special coating, any required patch work

should be done before lowering unit.

8. Slide beams in close to column. Lower the assembly and rest

the clamp ears on the beams. Remove the sling.

Figure A5.1

Figure A5.3.1

Loading...

Loading...