9

H: TROUBLE SHOOTING

H1: TROUBLE SHOOTING

INSUFFICIENT PRESSURE

1. Speed too slow (check voltage)

2. Impeller trimmed incorrectly

3. Impeller loose

4. Impeller plugged

5. Wear rings worn

6. Entrained air in pump

7. Leaking joints or bowl casings

8. Wrong rotation

9. Incorrect impeller adjustment

NO LIQUID DELIVERED

1. Pump suction broken (water level below inlet)

2. Suction valve closed

3. Impeller plugged

4. Strainer clogged

5. Wrong rotation

6. Shaft broken or unscrewed

7. Impeller loose

8. Barrel or discharge not vented

9. Driver inoperative

VIBRATION

1. Motor imbalance (electrical)

2. Motor bearing is not properly seated or is worn

3. Motor drive coupling out of balance or alignment

4. Misalignment of pump, casing, discharge head,

column, and/or bowls

5. Discharge head misaligned by improper mounting

or pipe strain

6. Bent shafting

7. Worn pump bearings

8. Clogged impeller or foreign material in pump

9. Improper impeller adjustment

10. Vortex problems in sump

11. Resonance (system frequency at or near pump speed)

12. Cavitation

13. Impeller out of balance

INSUFFICIENT CAPACITY

1. Speed too slow

2. Impeller trimmed incorrectly

3. Impeller loose

4. Impeller or bowl partially plugged

5. Leaking joints

6. Strainer or suction pipe clogged

7. Suction valve throttled

8. Low water level

9. Wrong rotation

10. Insufficient submergence

11. Insufficient N.P.S.H.

12. Incorrect impeller adjustment

13. Worn pump

14. Pressure higher than design

USING TOO MUCH POWER

1. Speed too high

2. Improper impeller adjustment

3. Improper impeller trim

4. Pump out of alignment

5. Coupling out of alignment

6. Pumping foreign material

7. Lubrication oil too heavy

8. Bent shaft

9. Tight bearing or packing

10. Specific gravity or viscosity of fluid higher than design

11. Worn pump

12. Damaged pump

13. Partial freezing of pump liquid

ABNORMAL NOISE

1. Motor noise

2. Pump bearing running dry

3. Broken column bearing retainers

4. Broken shaft or oil tubing

5. Impeller dragging on bowl case

6. Cavitation, due to insufficient N.P.S.H.A. and/or

submergence

7. Foreign material in pump

8. Excessive fluid velocity in pipe system

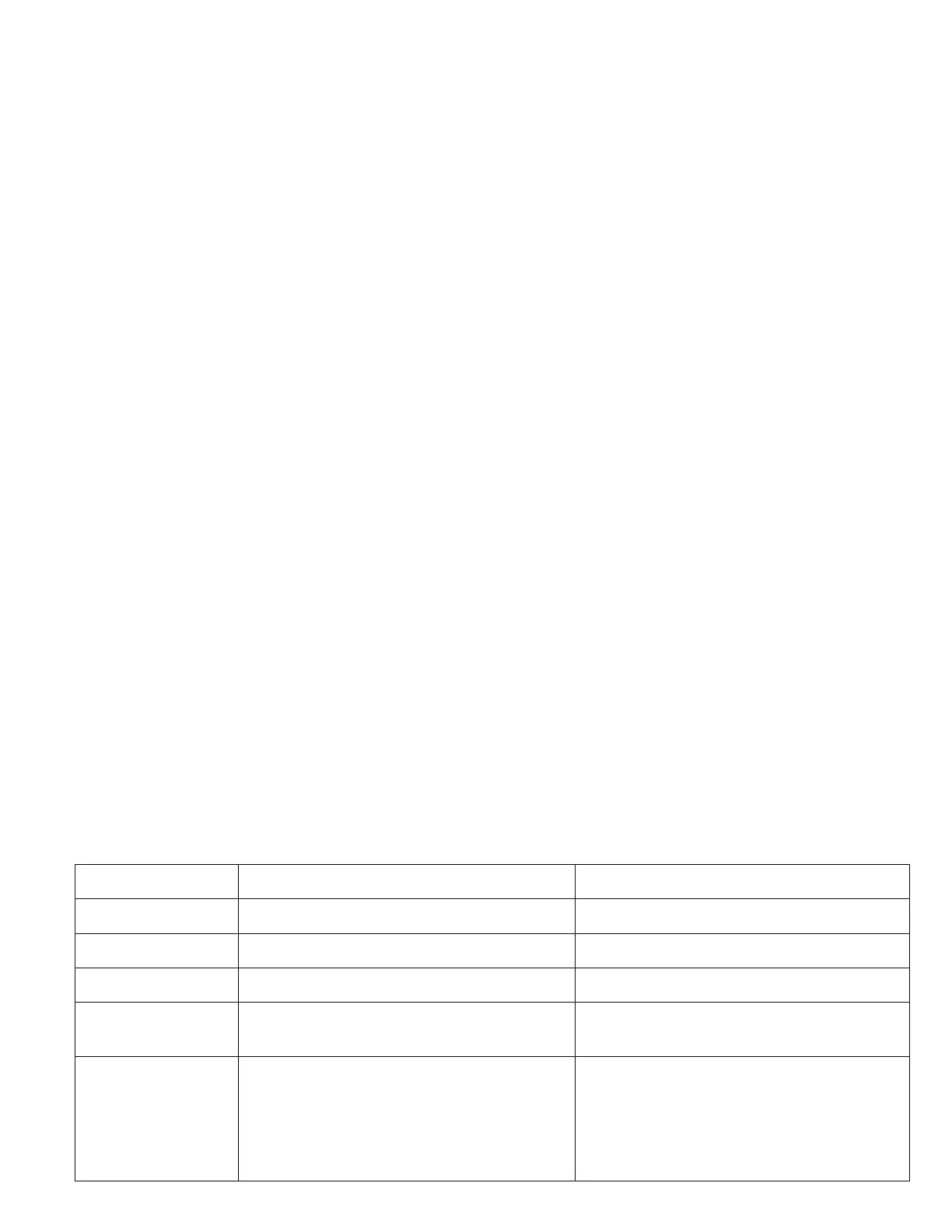

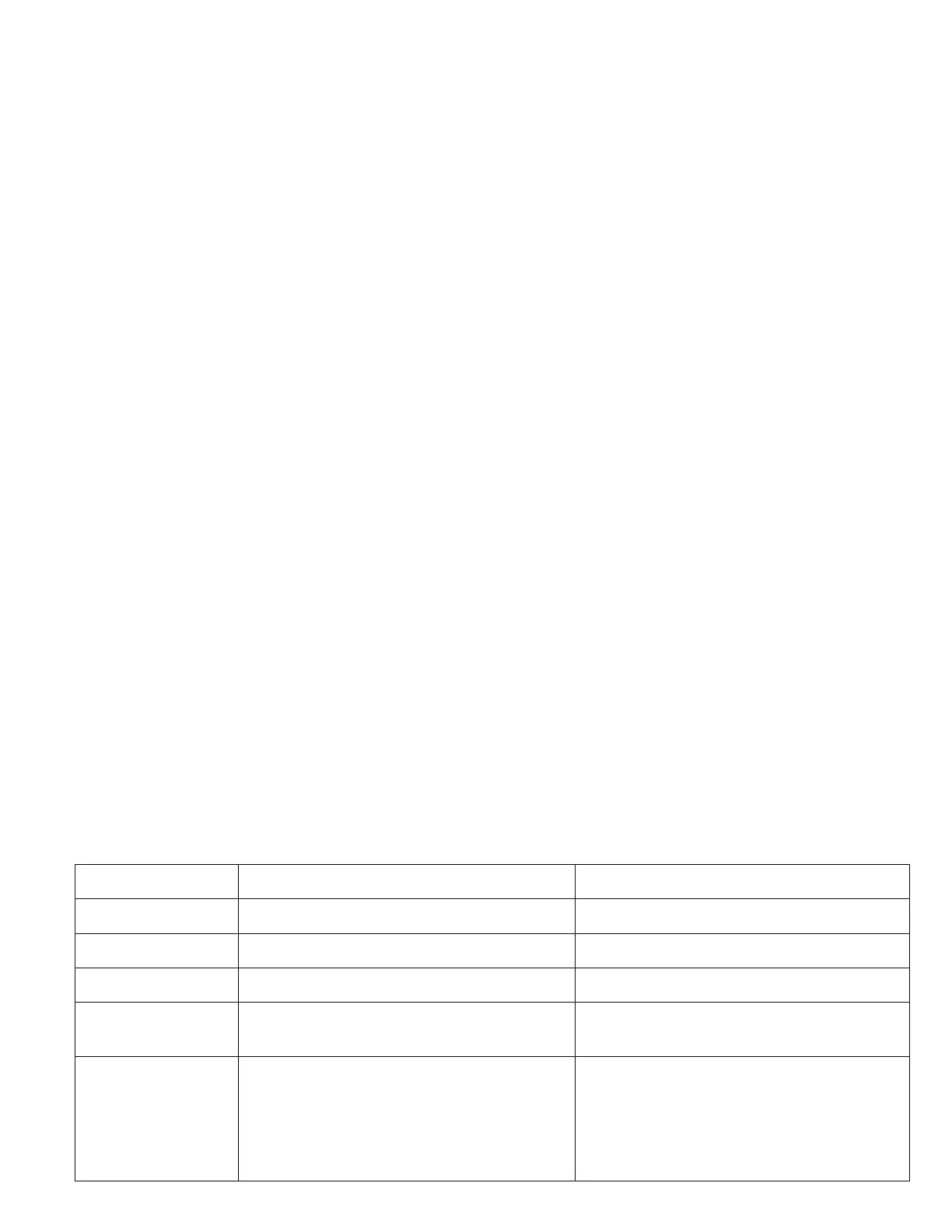

H2: IMPELLERS

TROUBLE SOURCE PROBABLE CAUSE REMEDY

Wear on exit vanes and

shrouds

Abrasive action

Replace impeller if excessive. Consider coating or

upgrading material.

Pitting on entrance vanes of

impellers

Cavitation Correct condition or upgrade material to extend life.

Pitting on impellers and

bowl castings

Corrosion/Erosion

Investigate cost of different materials vs. frequency of

replacements.

Wear on impeller skirts and/

or bowl seal ring area

1. Abrasive action or excess wear impeller skirts to

function as bearing journal

2. Impeller set too high

1. Install new bearings and wear rings. Upgrade material

if abrasive action.

2. Re-ring and adjust impellers correctly.

Impeller loose on shaft

(extremely rare occurrence)

1. Repeated shock load by surge in suction or discharge

line (can loosen first or last stage impellers)

2. Foreign material jamming impeller (may break shaft or

trim over loads before impeller becomes too loose)

3. Differential expansion due to temperature

4. Parts improperly machined and/or assembled

5. Torsion loading on submersible pumps

1. Re-fit impellers. If collet mounted, consider changing to

key mounting.

2. Remove cause of jamming.

3. If collet mounted, consider change to key mounted.

Avoid sudden thermal shock.

4. Correct parts if necessary and refit.

5. Add keyway to collet mounting.

Loading...

Loading...