28

CHECKING BLADE WEAR

REPLACING BLADES

1. Manually rotate driveline to align blade lock nut

with access hole in top of deck behind gearbox.

2. Remove old blade bolts and blades.

3. Use new blade bolt hardware to install new

blades.

4. Tighten blade bolt lock nuts to 425 ft-lbs.

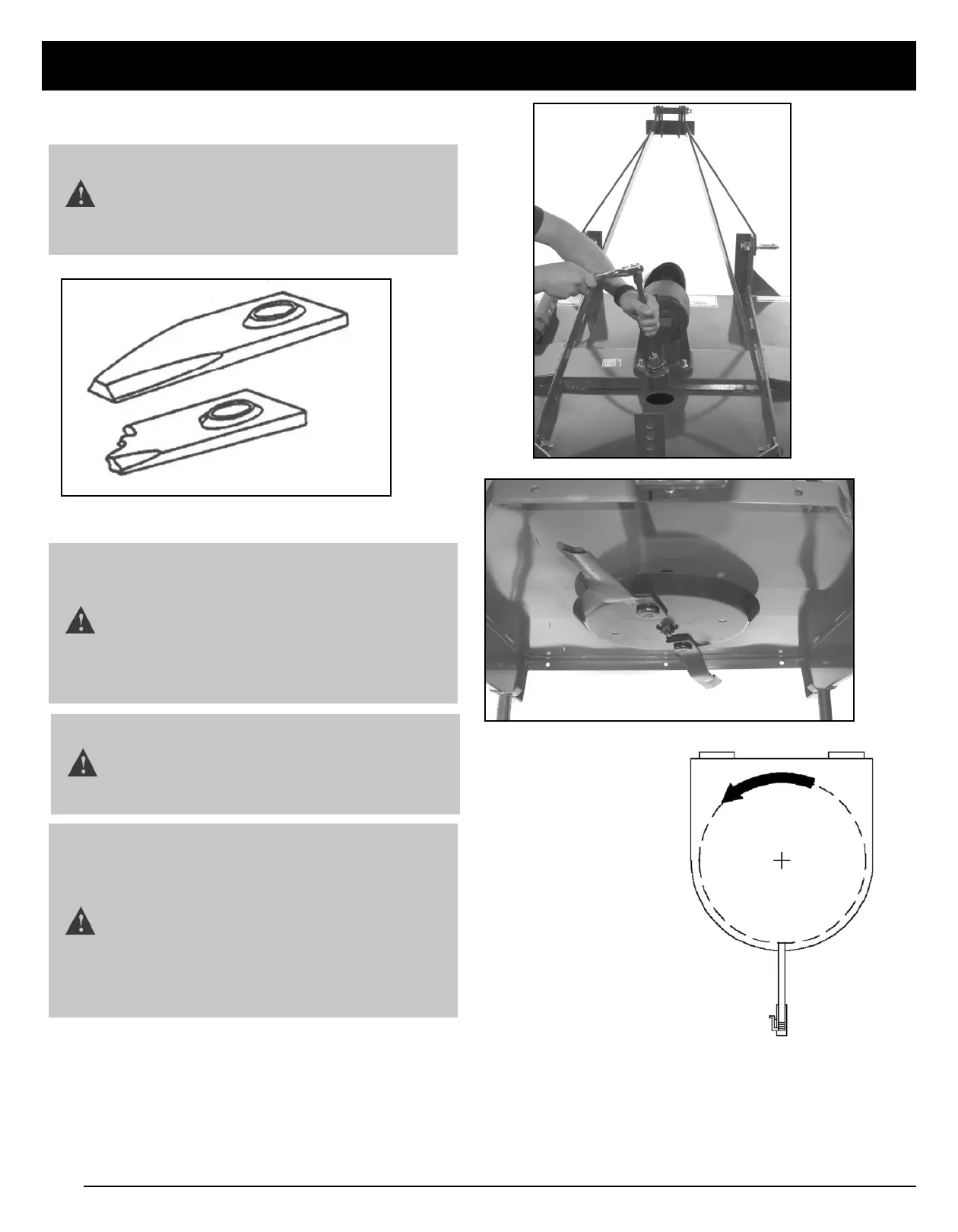

DIRECTION OF

BLADE ROTATION

IMPORTANT: Cutter

shown is viewed from the

top. Take special note of

blade rotation shown by

the arrow.

SERVICE

IMPORTANT: Operating with blades that are

not alike will cause vibration. Always replace

worn or broken blades in pairs. Never replace

a single blade. Check blades regularly for

wear or breakage.

IMPORTANT: Operating with loose blade

hardware will damage the blade pan and

blades. Whenever the blades have been

removed or replaced, blade hardware MUST

also be replaced. Check blade hardware

torque after one hour of operation and every

eight (8) hours thereafter.

CAUTION: When replacing blades, blade

hardware, and blade pan it will be necessary

to work underneath cutter. Be sure to support

cutter frame at all four corner locations with

safety shop stands, blocks, or other firm

supports to prevent accidental lowering.

Do not position safety stands under wheel

support because these components can

rotate.

NOTE: Suction blades have cutting edge on

one side only. Take note of blade rotation

when installing blades. (See DIRECTION OF

BLADE ROTATION in this section.)

Loading...

Loading...