29

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

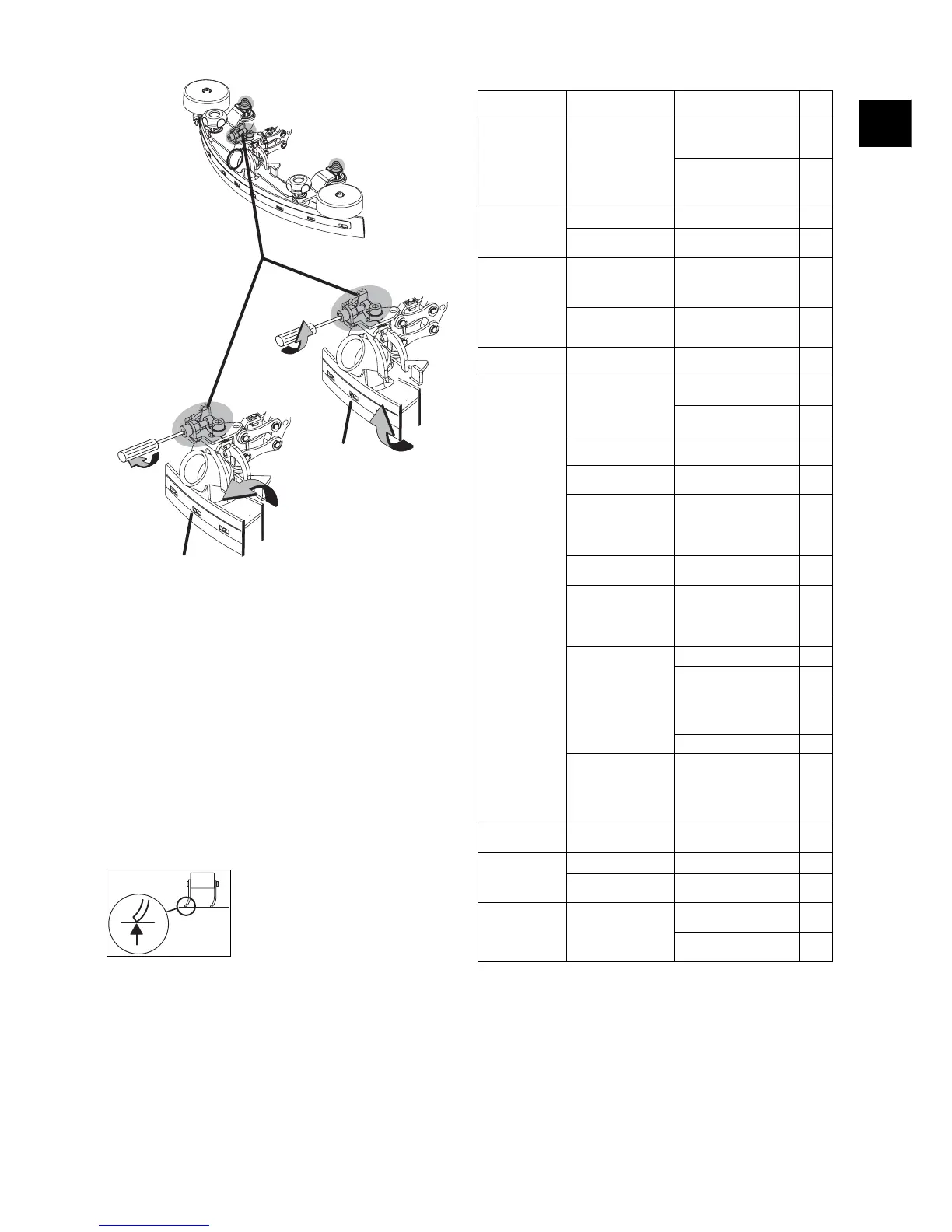

Squeegee settings

If you experience an uneven suction result, the settings of the suction unit

should be corrected. Proceed as follows:

Before carrying out the adjustment, check that:

• the blades are not damaged (replace).

• the suction unit is not damaged.

Height setting (Fig. A)

• First check the distance between the floor and the running or support

wheels.

The distance between running wheels number 1 and 2 and the floor must be

between 1 mm and 3 mm in each case (with the blades standing vertically).

• Switch the machine off using the keyswitch and then lower the squeegee.

• To correct, loosen the hexagonal nuts number 1 and 2, and then adjust the

height by turning the Allen screw. Then firmly re-tighten the hexagonal nuts

Number 1 and 2.

• Check the result while cleaning (see illustration below) and go to "Angle of

Inclination" (Fig. B) if the result is unsatisfactory.

Angle of inclination(Fig. B)

• Switch the machine off.

• Lower the squeegee and move the machine forward by a few centimetres

so that the blades can adopt their working position.

• To correct, loosen Allen screw number 3 and adjust the angle of inclination

by turning Allen screw number 4.

Note: Carry out the correction with gradual adjustments!

Firmly retighten Allen screw number 3 after the correction has been made. Then

move the machine forward by a few centimetres and check the setting of the

scraper edge that has been achieved. Repeat this procedure until the correct

inclination is obtained.

Malfunctions

Transport

• Disconnect the battery from the machine using the battery disconnection

mechanism.

Transport the machine in an upright position and disconnect/remove the

batteries for transportation.

Make sure that the machine is securely fastened within the transportation

vehicle.

Refer to Page 30 for the dimensions and weights.

A correct angle has been achieved when the tip

of the rear blade (x) is distributed over the

complete width of the suction unit.

B

A

x

x

4

3

1

2

4

3

Malfunction Possible causes Troubleshooting page

Machine does not

run

Maschine switched off

• Switch on the

keyswitch.

23

• Connect the battery to

the machine with the

battery disconnection

socket.

23

Battery/mains

unit malfunction

(display on

control panel)

Discharged batteries

• Recharge batteries

24

Batteries/battery

charger defective

• Call for technical

assistence

Batteries not

sufficiently

charged

Power cord not

plugged in or

defective

• Plug in the power cord

• Call for technical

assistence

Batteries or battery

charging unit

defective

• Call for technical

assistence

Brush does not

turn

Motor runs but not

tool

• Call for technical

assistence

Poor vacuum

performance

Floor remains

wet

Soiled solution

not picked up

Float closes the air

inlet at the vacuum

motor (overfill

protection recovery

tank)

• Check the recovery

tank is not full

27

• Check that the float is

functioning correctly.

28

Squeegee not on the

floor

• Lower the squeegee.

26

Suction hose not

connected

• Connect suction hose

26

Check the seal on the

tank lid for cracks/dirt

• Clean the seal, or

replace if defective

Vacuum air filter

blocked

• Remove the blockage

Hose or nozzle

blocked (e.g. by

pieces of wood or

residual material)

• Remove the blockage

The blades do not

adjust well to the floor

consistancy

• Clean the squeegee

• Change/turn the

blades

28

• Check that the

squeegee suspension

is functioning correctly

• Squeegee adjustment 29

Dirt sieve full (yellow)

• Remove the dirt sieve

• Knock out the coarse

dirt from the sieve and

rinse it under running

water.

27

Vacuum switched

off

Recovery tank full

• Empty the recovery

tank

27

Insufficient

outflow of

cleaning solution

Solution tank empty

• Fill the solution tank

26

Solution tank filter

blocked

• Clean solution tank

filter

27

Foam or liquid

leaking from the

machine

Float malfunction

• Turn off the suction

aggregate

23

• Check that the float is

functioning correctly.

28

Loading...

Loading...