Twin City Engineering Supplement ES-895

5

AIRFLOW

5

6

2

4

3

1

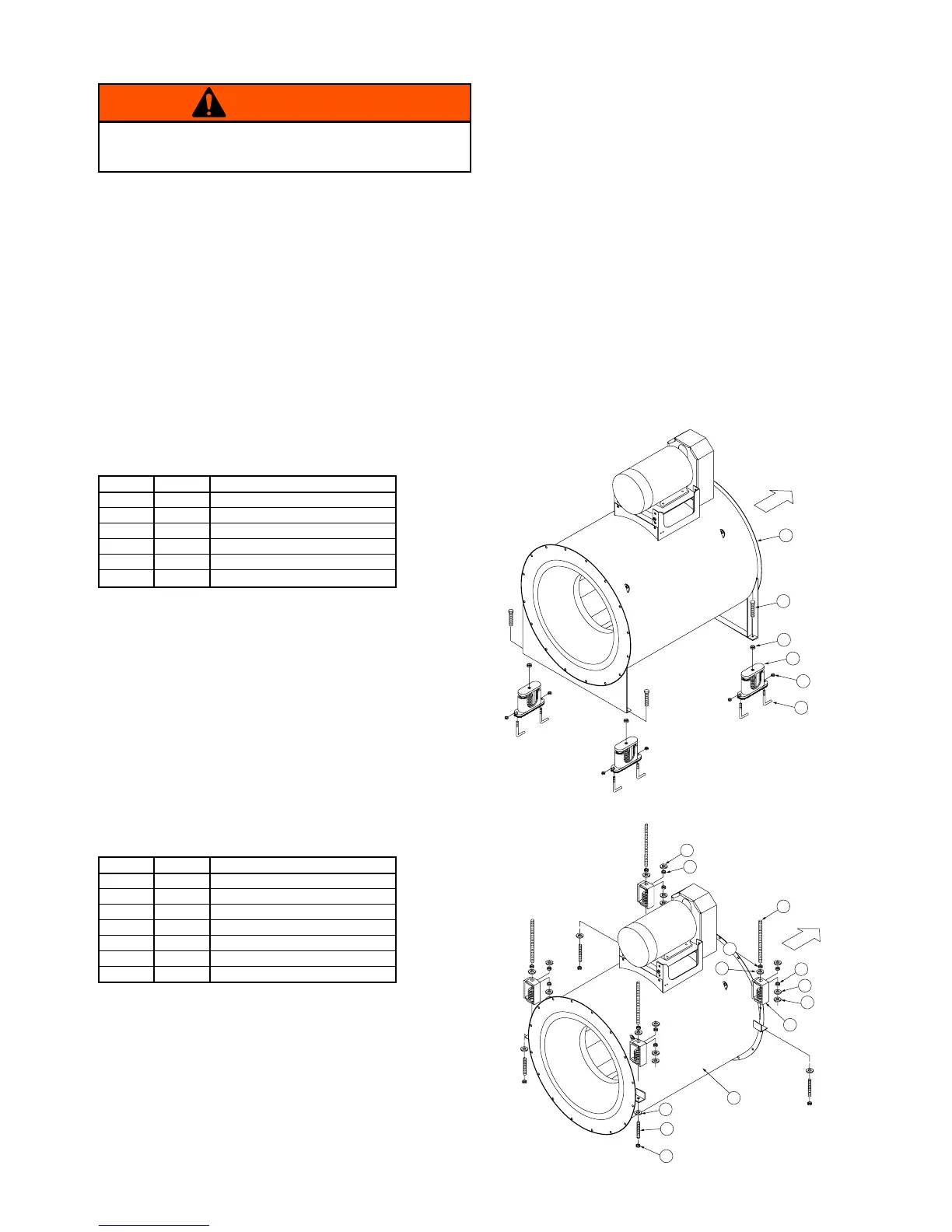

Figure 5. Typical Horizontal Mounting with Vibration Isolators

ITEM QTY. DESCRIPTION

01 1 TSL or QSL Fan

02 4 Vibration Isolator*

03 4 Adjusting & Leveling Bolt

04 4 Hex Nut**

05 8 Hex Nut**

06 8 Anchor Bolt**

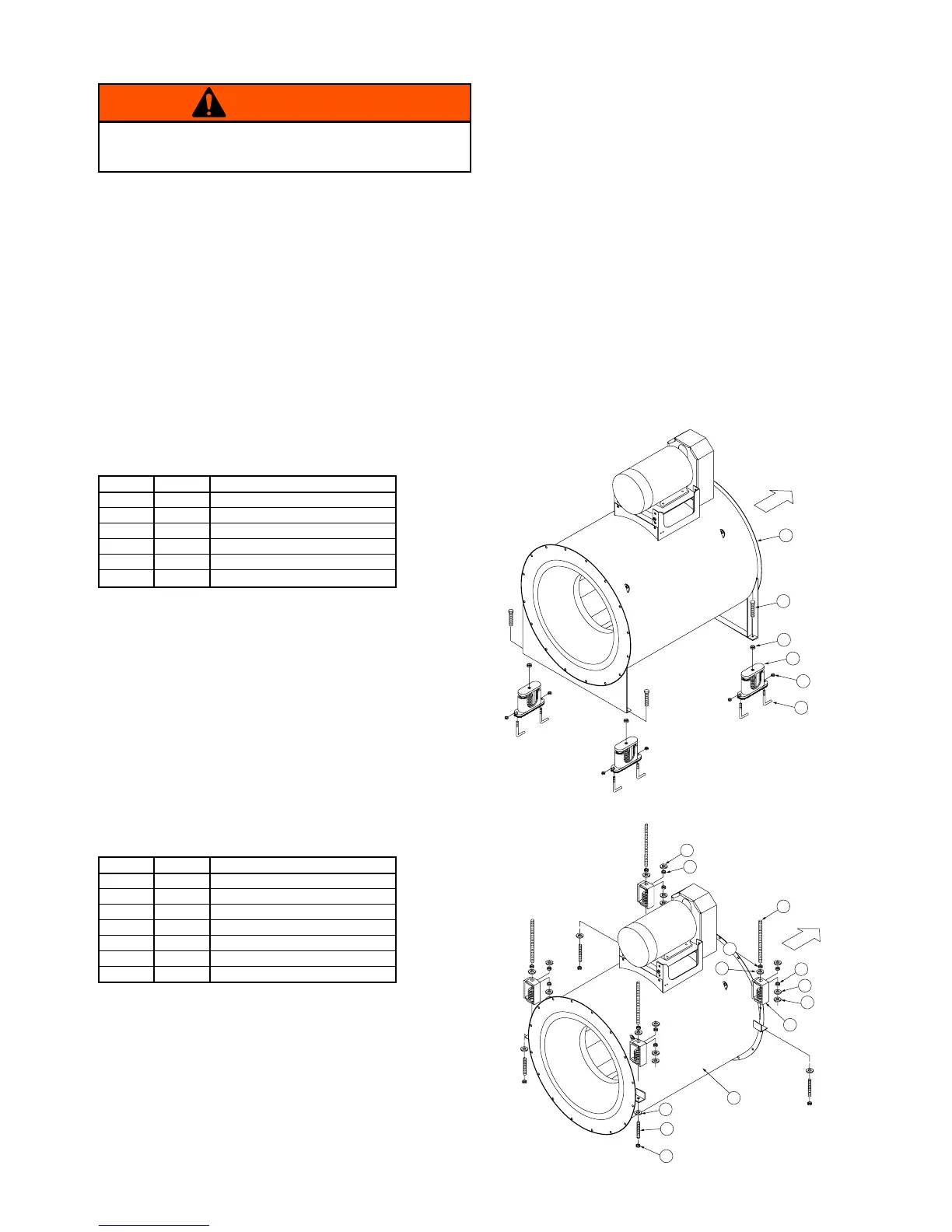

Figure 6. Typical Horizontal Mounting with Vibration Hangers (Ceiling Hung)

ITEM QTY. DESCRIPTION

01 1 TSL or QSL Fan

02 4 Spring Hanger*

03 4 Neoprene Washer

04 32 Steel Washer**

05 32 Hex Nut**

06 4 Threaded Rod

07 4 Hanger Rod**

NOTE:

*1. Spring hangers are optional accessories.

**2. Hanger rods, nuts and washers supplied by customer.

NOTES:

*1. Vibration isolators are optional accessories.

**2. Anchor bolts and hardware supplied by customer.

5

5

4

4

2

1

3

5

6

4

7

5

4

AIRFLOW

Operation Checklist

Check fan mechanism components:

□ Nuts, bolts, setscrews are tight.

□ Mounting connections are properly made and

tightened.

□ Bearings are properly lubricated.

□ Wheel, drives and fan surfaces are clean and

tightened.

□ Rotating assembly turns freely and does not rub.

□ Drives on correct shafts, properly aligned, and

properly tensioned.

Check fan electrical components:

□ Motor is wired for proper supply voltage.

□ Motor was properly sized for power of rotating

assembly.

□ Motor is properly grounded.

□ All leads are properly insulated.

Trial “bump”:

□ Turn on power just long enough to start assembly

rotating.

□ Check rotation for agreement with rotation arrow.

□ Listen for any unusual noise.

Run unit up to speed:

□ Bearing temperatures are acceptable (<200°F) after

one to two hours of operation.

□ Check for excess levels of vibration. Filter in readings

should be 0.15 inches per second or less.

After one week of operation:

□ Check all nuts, bolts and setscrews and tighten if

necessary.

□ Re-adjust drive tension if necessary.

Verify that proper safety precautions have been

followed. Electrical power must be locked off.

WARNING

Loading...

Loading...