409-10204

Rev G

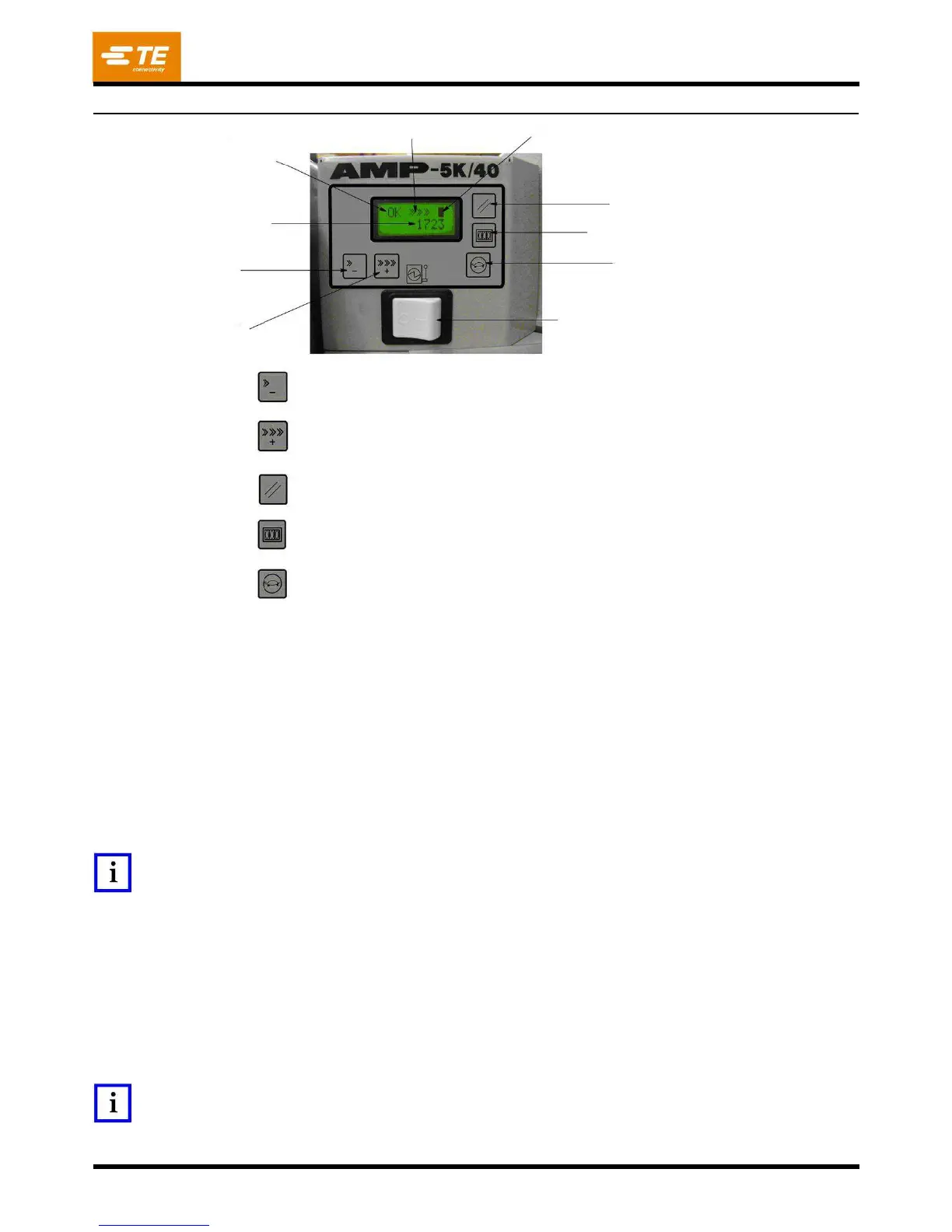

Figure 9

4. Set the crimp height and insulation crimp discs so that the letters and numbers on the applicator pad

align with the front pad on the ram post adapter.

5. If the applicator is an air-feed type, make sure the front door cover is closed, then connect the airlines

to the valves located on the back of the machine.

NOTE

Quick Disconnect Coupling PN 23238-1 is required to run air-feed applicators.

6. Adjust the reel support for side-feed or end-feed product, depending on the applicator being used.

7. Mount the terminal strip guide on the left sheet metal guard for side-feed product, or on the right sheet

metal guard for end-feed product, depending on the applicator being used.

8. Mount the terminal reel on the reel support. Thread the terminal strip through the guard and into the

applicator according to the instruction sheet included with the applicator. If necessary, adjust the

lubricator bowl.

9. Align the product reel to the applicator by adjusting the reel flanges.

10. Close the guard.

NOTE

The guard door must be closed in order to operate the machine. See paragraph 4.4.C.

Machine

Status/

Error

Code

Decrease

Speed

--

Decrease

the

motor

speed

for

normal

cycle

operation

and

for

jogging.

Increase

Speed

--

Increase

the

motor

speed

for

normal

cycle

operation

and

for

jogging.

Error

Reset

--

Clears

the

displayed

error

code.

Count

Reset

--

Clears

the

batch

count

to

0.

Jog

--

Causes

the

DC

motor

to

rotate

at

the

jog

speed

set

by

the

Increase

/

Decrease

Speed.

Speed

Indication

-

-

Each

“>”

represents

a

portion

of

the

full

operation

or

jog

speed

setting.

Minimum

speed

is

denoted

with

a

single

“>.

Maximum

speed

is

denoted

by

“>>>>>>.”

Machine

Status

/

Error

Code

Display

--

Displays

“OK”

if

there

is

no

error

code

being

displayed

or

“ERRxxx”

when

an

error

has

occurred.

The

“xxx”

represents

a

number

corresponding

to

an

error

described

in

the

error

code

table

(Figure

17).

Guard

Status

Indication

--

A

solid

“

"

indicates

that

the

guard

interlock

is

closed.

An

open

icon

in

this

display

indicates

that

the

guard

interlock

is

open.

The

DC

motor

will

not

run

when

the

guard

interlock

is

open.

Loading...

Loading...