25

Calibration Procedure

1) Connect a mV source to thermocouple input.

2) Connect a DVM to TP1.

3) Set mV source to give a reading of 3.00 volts at TP1.

(This should correspond to 300°C input = 12.2mV).

4) Connect DVM TP2.

5) Adjust VR1 to give reading of -2.81 volts at TP2.

6) Connect DVM to TP3.

7) Adjust VR2 to give reading of +4.14 volts at TP2.

8) Adjust VR3 so that it is in a position approximately half way between the positions

where LEDs 2 and 5 and LEDs 1 and 5 are illuminated.

PCB calibration is now complete and a check of binary output can be made using Table 1.

Air flow adjustment is dealt with in 'setting Up Procedure'.

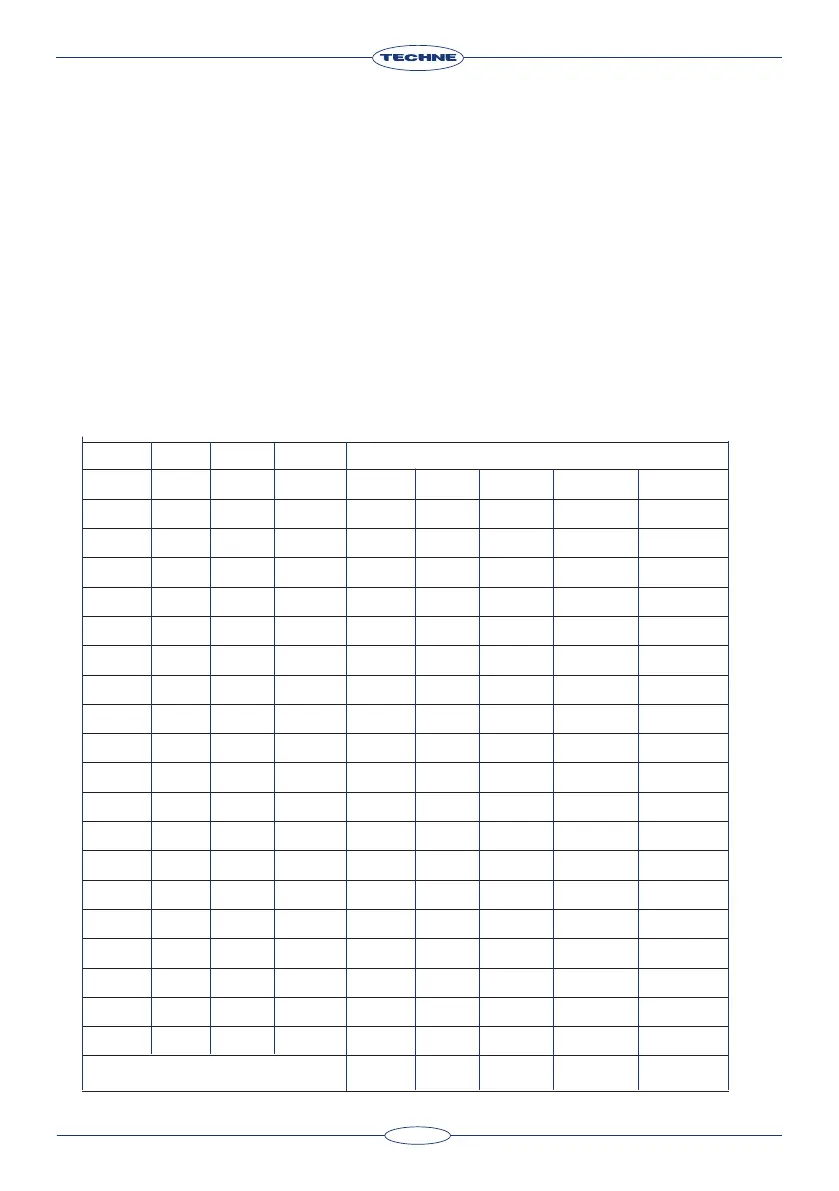

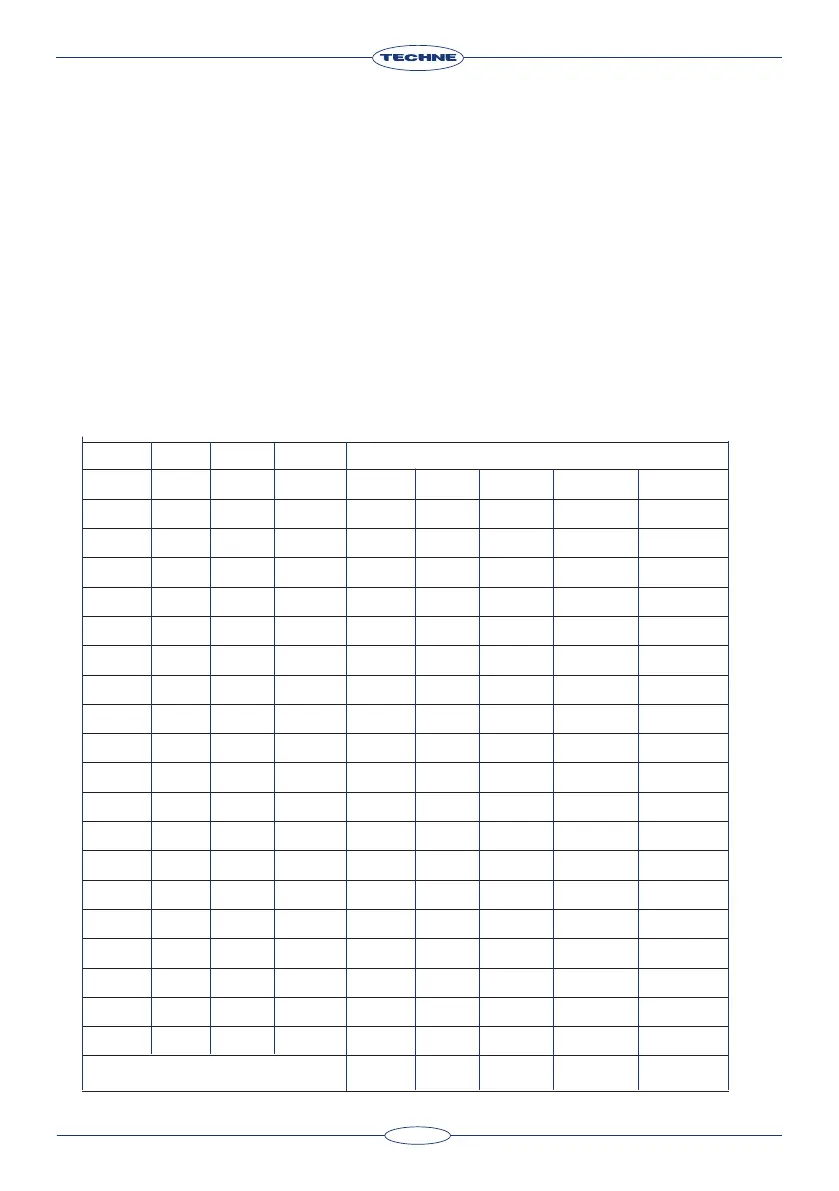

TABLE 1

TEMP TEMP Mv FLOW VALVE ENERGISED/WIRE COLOUR

°C °F litre/min 1 2 3 4 5

Brown Red Orange Yellow Green

25 77 1.0 29.0 X X X

50 122 2.0 29.0 X X X X

75 167 3.1 28.5 X X X

100 212 4.1 28.0 X X X

125 257 5.1 27.5 X X

150 302 6.1 21.0 X X X X

175 347 7.1 20.5 X X X

200 392 8.1 20.0 X X X

225 437 9.1 19.5 X X

250 482 10.2 19.5 X X X

280 536 11.4 19.0 X X

310 590 12.6 18.5 X X

340 644 13.9 18.0 X

370 698 15.1 12.5 X X X X

430 806 17.7 12.0 X X X

490 914 20.2 11.5 X X X

550 1022 22.8 11.0 X X

610 1130 25.3 11.0 X X X

Flow rate litre/min 0.5 1.0 1.5 9.5 18.0

Loading...

Loading...