Calibration-475

2. Connect the autotransformer to a suitable power

source.

5. Set the controls as given under Preliminary Control

Settings (given prior to Part I—Performance Check). Allow

at least 20 minutes warmup before proceeding.

3. Connect the 475 to the autotransformer output.

NOTE

4. Set the auto transformer output voltage to the center

of the voltage range selected by the Line Voltage Selector.

Titles for external controls of this instrument are

capitalized in this procedure (e.g., INTENSITY).

Internal adjustments are initial capitalized only (e.g.,

CRT Grid Bias).

POWER SUPPLY CALIBRATION

Equipment Required

1. Precision DC Voltmeter

4. Three-inch Screwdriver

2. DC Voltmeter

3. Test Oscilloscope

5. Variable Auto-Transformer

Control Settings

Preset instrument controls to the settings given under

Preliminary Control Settings.

1- Check Power Supply DC Levels and Ripple

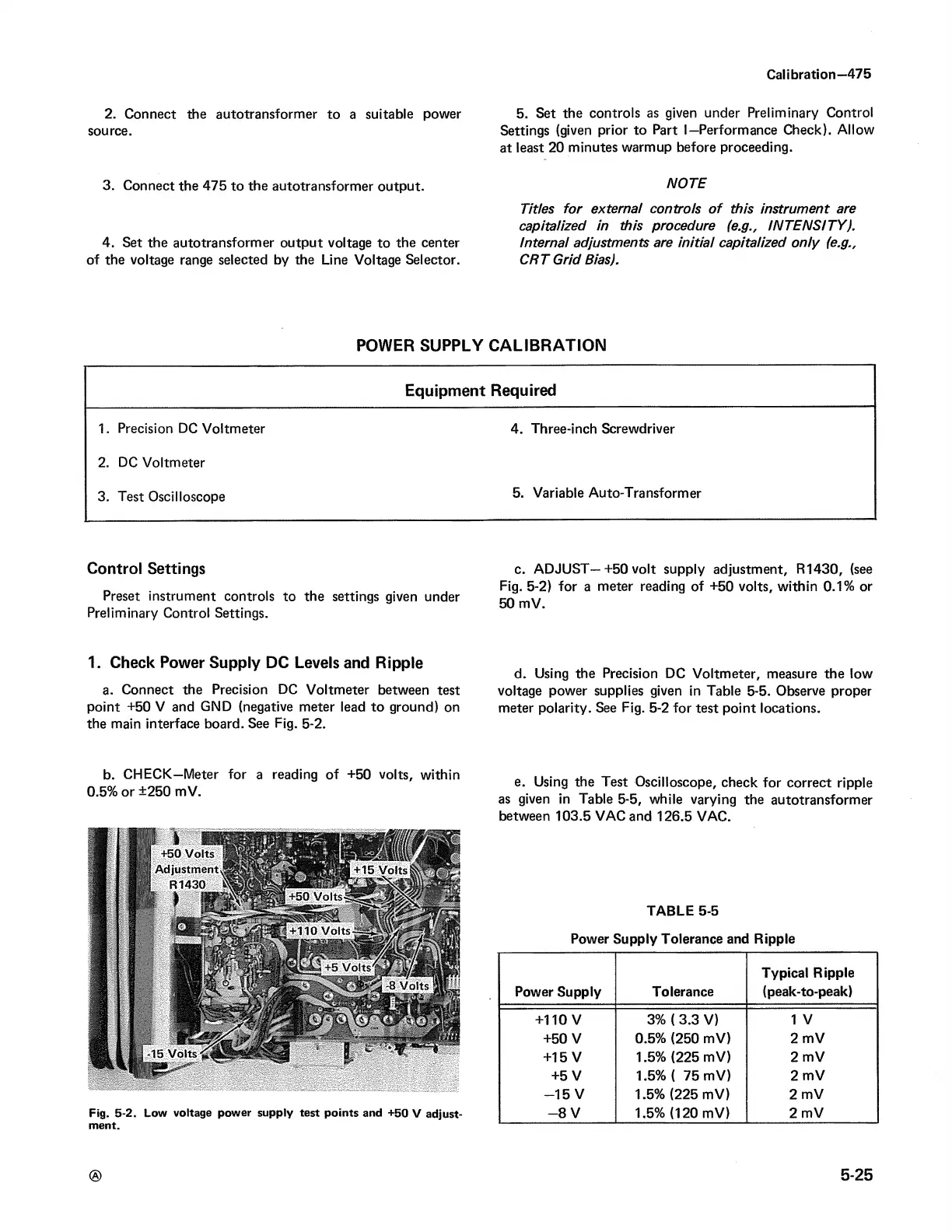

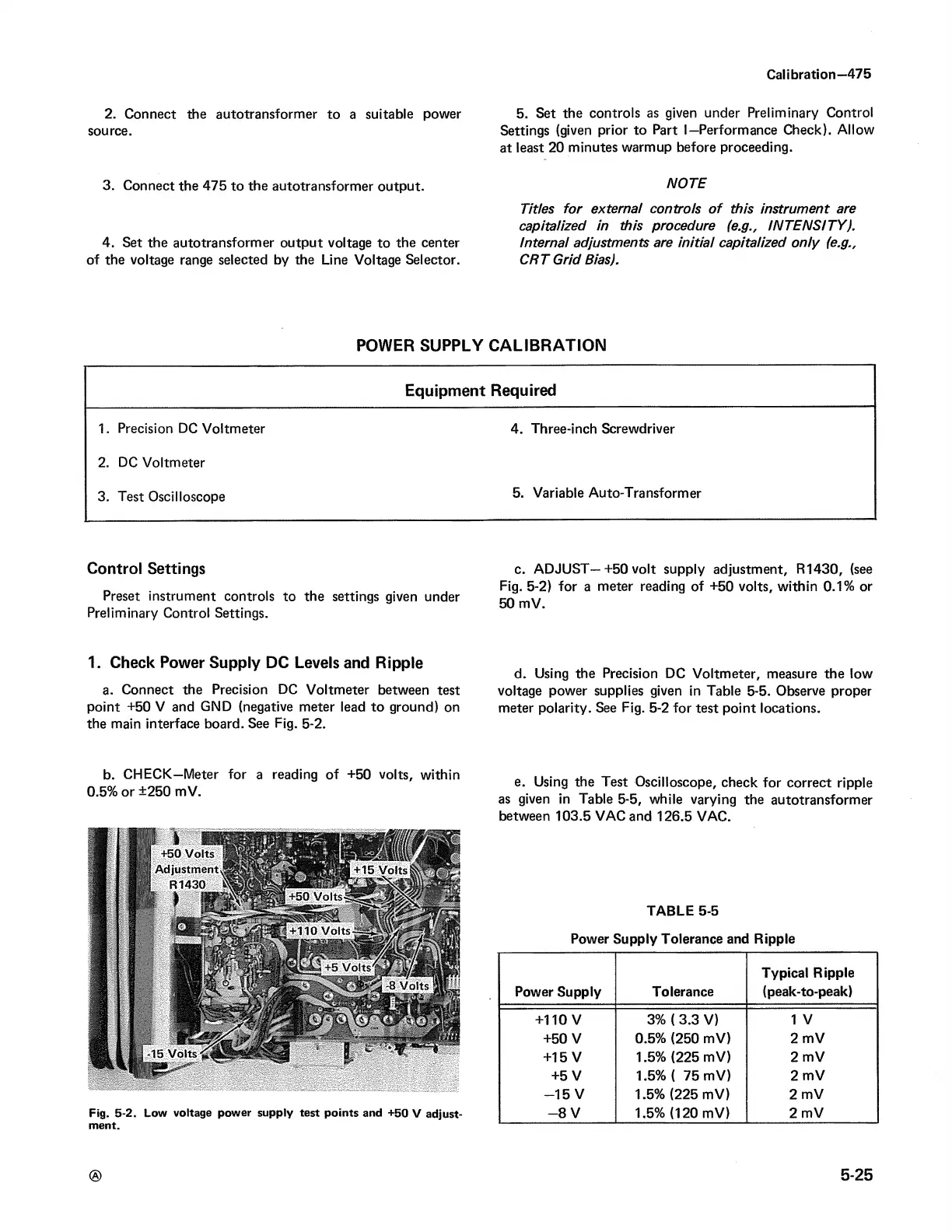

a. Connect the Precision DC Voltmeter between test

point +50 V and GND (negative meter lead to ground) on

the main interface board. See Fig. 5-2.

c. ADJUST—+50 volt supply adjustment, R1430, (see

Fig. 5-2) for a meter reading of +50 volts, within 0.1% or

50 mV.

d. Using the Precision DC Voltmeter, measure the low

voltage power supplies given in Table 5-5. Observe proper

meter polarity. See Fig. 5-2 for test point locations.

b. CHECK—Meter for a reading of +50 volts, within

0.5% or +250 mV.

Fig. 5-2. tow voltage power supply test points and +50 V adjust

ment.

e. Using the Test Oscilloscope, check for correct ripple

as given in Table 5-5, while varying the autotransformer

between 103.5 VAC and 126.5 VAC.

TABLE 5-5

Power Supply Tolerance and Ripple

Power Supply

Tolerance

Typical Ripple

(peak-to-peak)

+110 V 3% (3.3 V)

1 V

+50 V 0.5% (250 mV)

2 mV

+15 V

1.5% (225 mV)

2 mV

+5 V 1.5% ( 75 mV)

2 mV

-1 5 V

1.5% (225 mV)

2 mV

- 8 V

1.5% (120 mV)

2 mV

5-25

Loading...

Loading...