DEMOLITION

You have to operate the elimination of the materials in conformity with

the regulations in force. All materials must be divided by type (copper,

aluminium, plastic, electrical parts, etc)

DISMANTLING

In order to move away the automation, follow these instructions:

1 - cut off the power supply and disconnect the electrical installation;

2 - dismantle the control console and all the other components of the

installation.

If you have noticed that some components have been damaged, you

have to replace them.

CONFORMITY DECLARATION:

It’s in accordance with Machine Directive 39/89/CE and following

modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive 89/336/CEE and following

modify.

Low tension Directive 73/23/CEE and following modify.

Have been applied the following harmonized norms:

EN292/1/2, EN 294, EN60335-1, UNI EN 12453, and what applicable

of the EN12445-2000.

USE OF THE AUTOMATION

The gearmotor STONE 300-400-600 GR was designed and built for

the opening of gates with max of 5 m leaf or weight max. 200kg. The

CARDIN ELETTRONICA Spa assumes no responsibility for a purpose

other than that provided by gearmotor STONE 300-400-600 GR. Since

automation can be put into motion in view by button or remotely by

remote control, it is essential to check frequently the perfect efficiency

of all safety devices. It is advisable to check periodically (every six

months) the regulation of electronic friction of which must be equipped

the electronic control board.

PRELIMINARY CHECKS

1 - Read carefully the instructions enclosed in this manual.

2 - Make sure that the gate has a rather solid structure and that there

is no friction points in its movement.

3 - Make sure that the leaf is suitably balanced, even after the

installation of the gear motor.

4 - Check that the electrical installation is in accordance with the

characteristic required by the gear motor.

TECHINICAL DATA

SCHEDULED MAINTENANCE

Control of gate hinges and supports, balancing of the

gate

Check the status of welds and corrosion.

Unhook the engine and check the

balancing and the eventual points of

friction.

Controlling the sensitivity of electronic friction (torque

adjustment) of the control board.

Check the adjustment of the couple as

described in EN 12453 - EN 12445

Monitoring current dispersion

Verify that the dispersion of current is

less than 7.5 A

Verify that the safety warning signage is

complete and intact

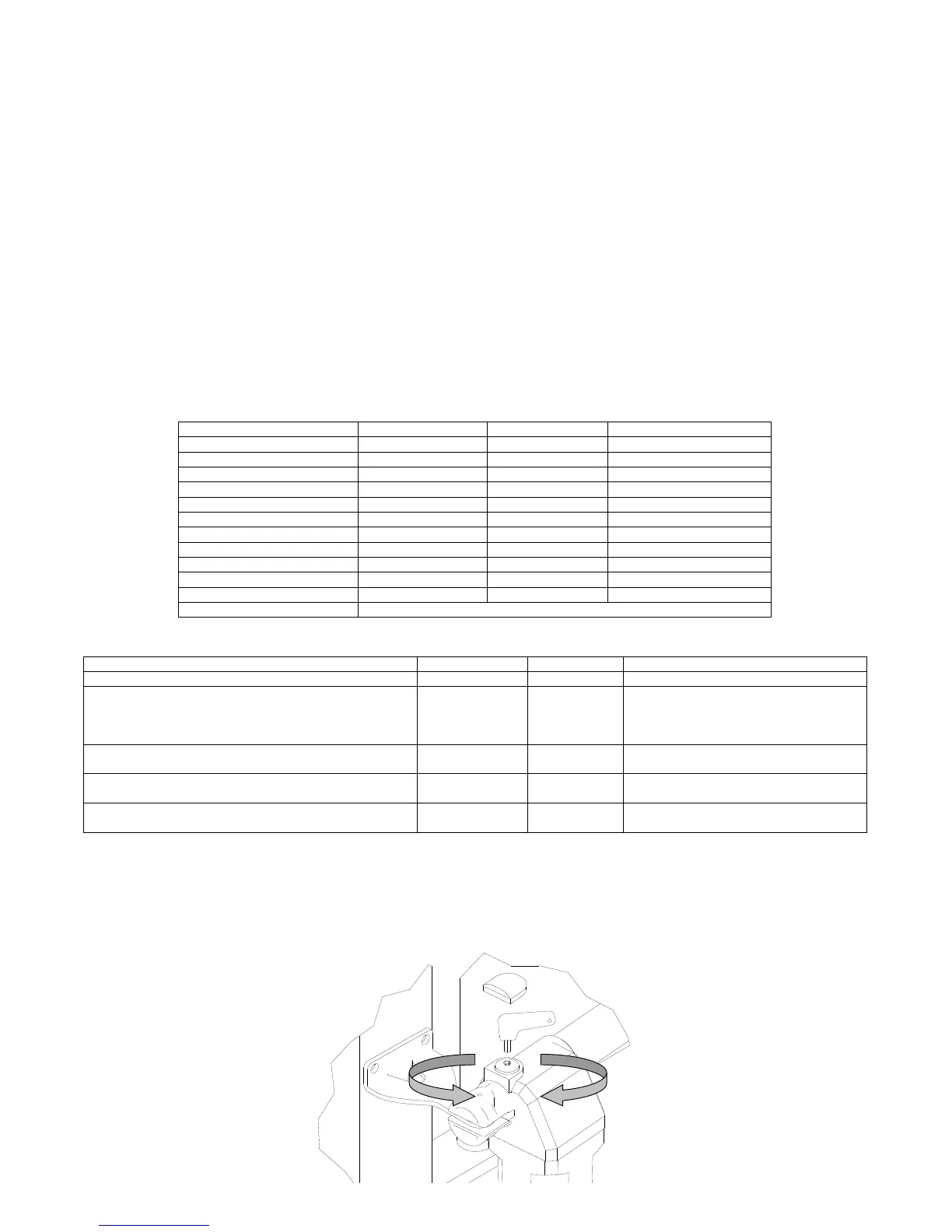

EMERGENCY MANOEUVRE

For the manual door locking and unlocking act with the supplied key on the screw C (See FIG 1-2).

1 - Remove the protection cap

2 - insert the key into the seat allocation as in Figure 1

3 - Turn the key in the sense of the arrow to the top of the gearmotor to unlock and in the opposite block.

Maximum length of the gate

Maximum weight of the gate

Loading...

Loading...