For the Technology 170

For the Technology 200

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +160Adc ±3% and the output

voltageis equal to +26.4Vdc ±5%;if the output current reading

is not 160A ±3%, adjust the current using trimmer IMAX R13

onthe primary board ( ).

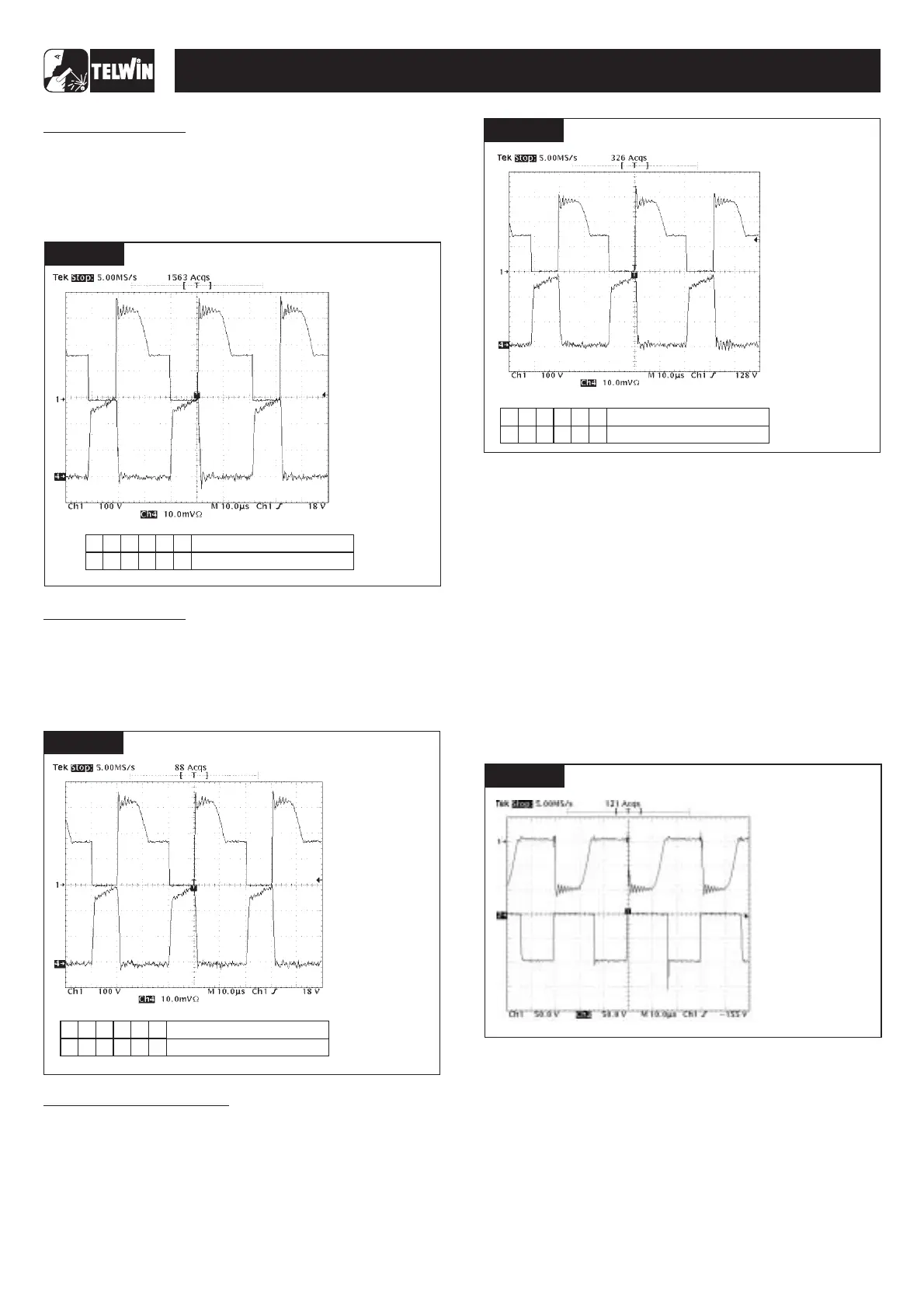

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +180Adc ±3% and the output

voltageis equal to +27.7Vdc ±5%;if the output current reading

is not 180A ±3%, adjust the current using trimmer IMAX R13

onthe primary board ( ).

Fig.I

fig.3

Fig.J

fig.3

For the Technology 186CE/GE

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +145Adc ±3% and the output

voltageis equal to +25.8Vdc ±5%;if the output current reading

is not 145A ±3%, adjust the current using trimmer IMAX R13

onthe primary board ( ).

- switchoff the ohmicload and switchoff the main switch.

- set up the dual trace oscilloscope, connecting probe CH1 x

100 to the anode of diode D1 or D2 and probe CH2x100 to the

anode of diode D3 or D5.Earth connections are both made to

thesecondary dissipator;

- remove the multimeter from the OUT+ and OUT- bump

contacts;

- set up the ohmic load with the switch settings according to the

relevantTechnologymodel (seetablesat point 1.2D);

- on the front panel position the current potentiometer R7 to the

maximum (turn the knob clockwise as far as it will go) and

switch onthe main switch;

- activate the static load generator and make sure that the

waveforms displayed on the oscilloscope resemble those in

- deactivate the static load generator and switch off the main

switch.

Set up the ohmic load as shown in the table in and the

current potentiometer on approx. 80A. Position switch SW1 on

HARD (in the centre), start the ohmic load and make sure the

output current reading shows approx. 110A ±10% then returns to

thecurrent setting

.

On the front panel set switch SW1 to SOFT (as low as it will go and

the welding current to maximum). Under the relevant load

Fig.K

fig.3

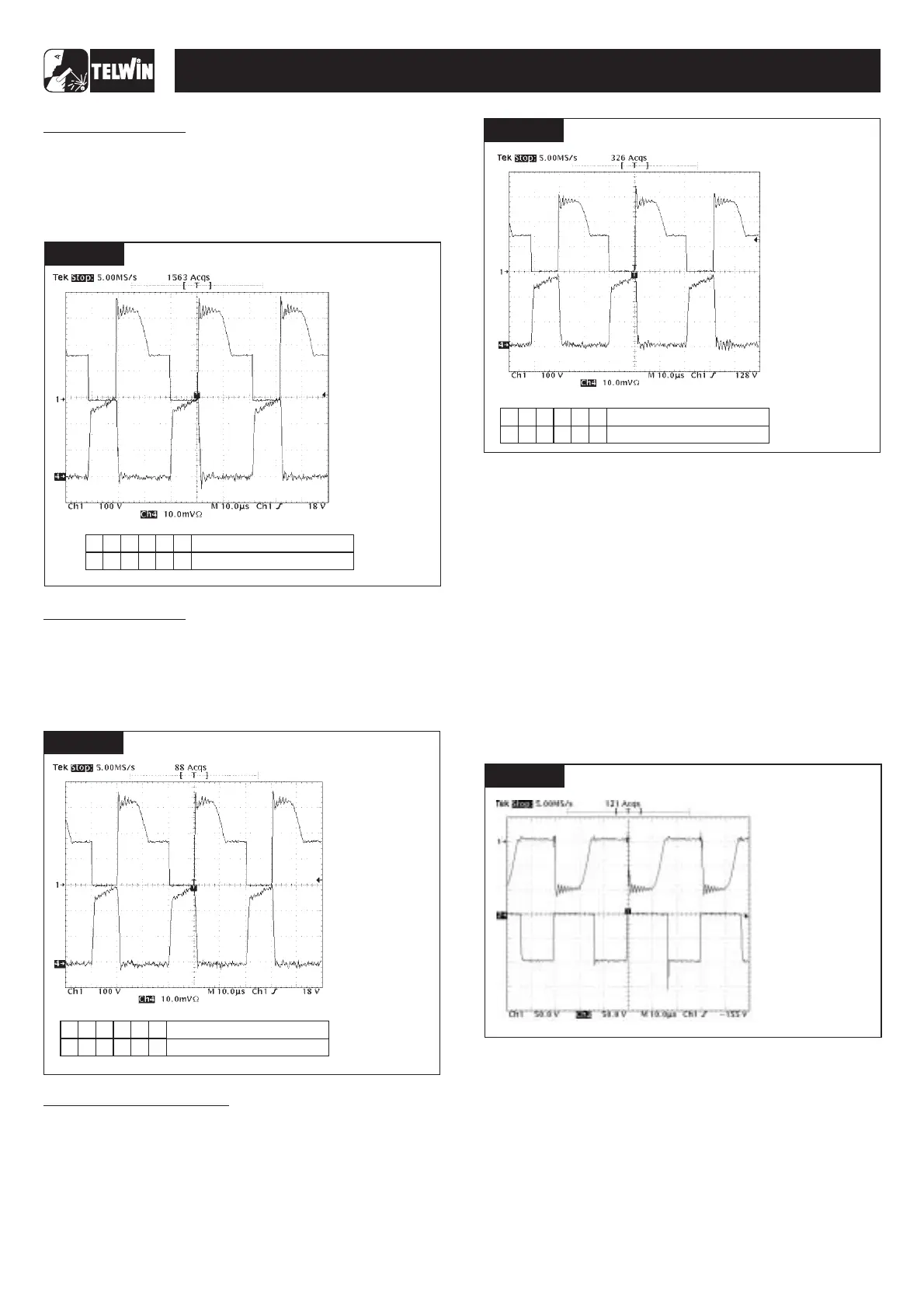

E) Checkingthe secondary diode voltages:

fig.L;

A)Arc Force test

Fig. G

B)Runningtime test andclosingthe machine

1.3 Operational tests

-16-

FIGURE E

6

3

2

1

4

5

333332

FIGURE J

TECHNOLOGY 150-170-200-186CE/GE

Number switch

Position switch

FIGURE E

FIGURE I

Number switch

Position switch

6

3

2

1

4

5

333222

SETTINGS

· THE FREQUENCY IS

32.5KHz ±20%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS

60A ±10%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =20A;

· 10mV/Div;

· 10 sec/Div.µ

VERIFY THAT

FIGURE E

6

3

2

1

4

5

333222

FIGURE K

Number switch

Position switch

SETTINGS

· THE FREQUENCY IS

32.5KHz ±20%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS

58A ±10%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =20A;

· 10mV/Div;

· 10 sec/Div.µ

VERIFY THAT

SETTINGS

· THE FREQUENCY IS

32.5KHz ±20%;

· AMPLITUDE CH1 IS

340V ±10%;

· AMPLITUDE CH4 IS

60A ±10%;

:

· PROBE CH1 x100;

· 100 V/Div;

· PROBE CH4 =20A;

· 10mV/Div;

· 10 sec/Div.µ

VERIFY THAT

FIGURE E

FIGURE L

SETTINGS

· REVERSE AMPLITUDE

ON CH1

250V.

· REVERSE AMPLITUDE

ON CH2

250V.

:

· PROBE CH1 x100;

· 50V/Div;

· PROBE CH2 x100;

· 50V/Div;

· 10 sec/Div.µ

VERIFY THAT

DOES NOT

EXCEED

DOES NOT

EXCEED

Loading...

Loading...