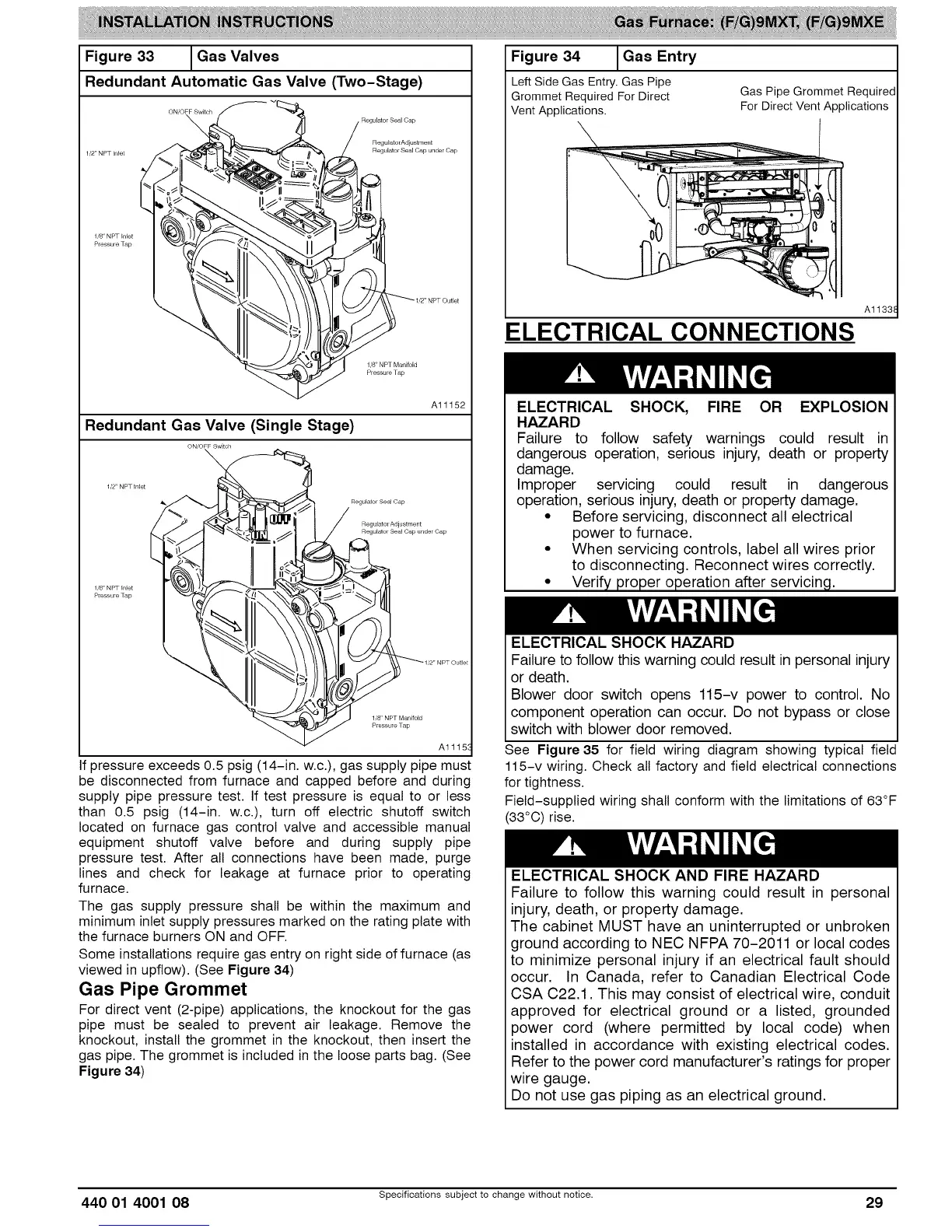

Figure33 /Gas Valves

Redundant Automatic Gas Valve (Two-Stage)

v

ON,OFF Switch

Regulator Seal Cap

RegulatorAdjustment

1,2" NPT Inlet Regulator Seal Cap under Cap

1/8" NPT Inlet

Pressure Tap

1/8" NPT Manifold

Al1152

Redundant Gas Valve (Single Stage)

Regulator Seal Cap

Regulatol Adjustment

Regulator Sea_ Cap l_nder Cap

1/8" NPT In_et

Pressure Tap

1,8' NPT Manifold

Pressure Tap

Al115{

If pressure exceeds 0.5 psig (14-in. w.c.),gas supply pipe must

be disconnected from furnace and capped before and during

supply pipe pressure test. If test pressure is equal to or less

than 0.5 psig (14-in. w.c.), turn off electric shutoff switch

located on furnace gas control valve and accessible manual

equipment shutoff valve before and during supply pipe

pressure test. After all connections have been made, purge

lines and check for leakage at furnace prior to operating

furnace.

The gas supply pressure shall be within the maximum and

minimum inletsupply pressures marked on the rating plate with

the furnace burners ON and OFF.

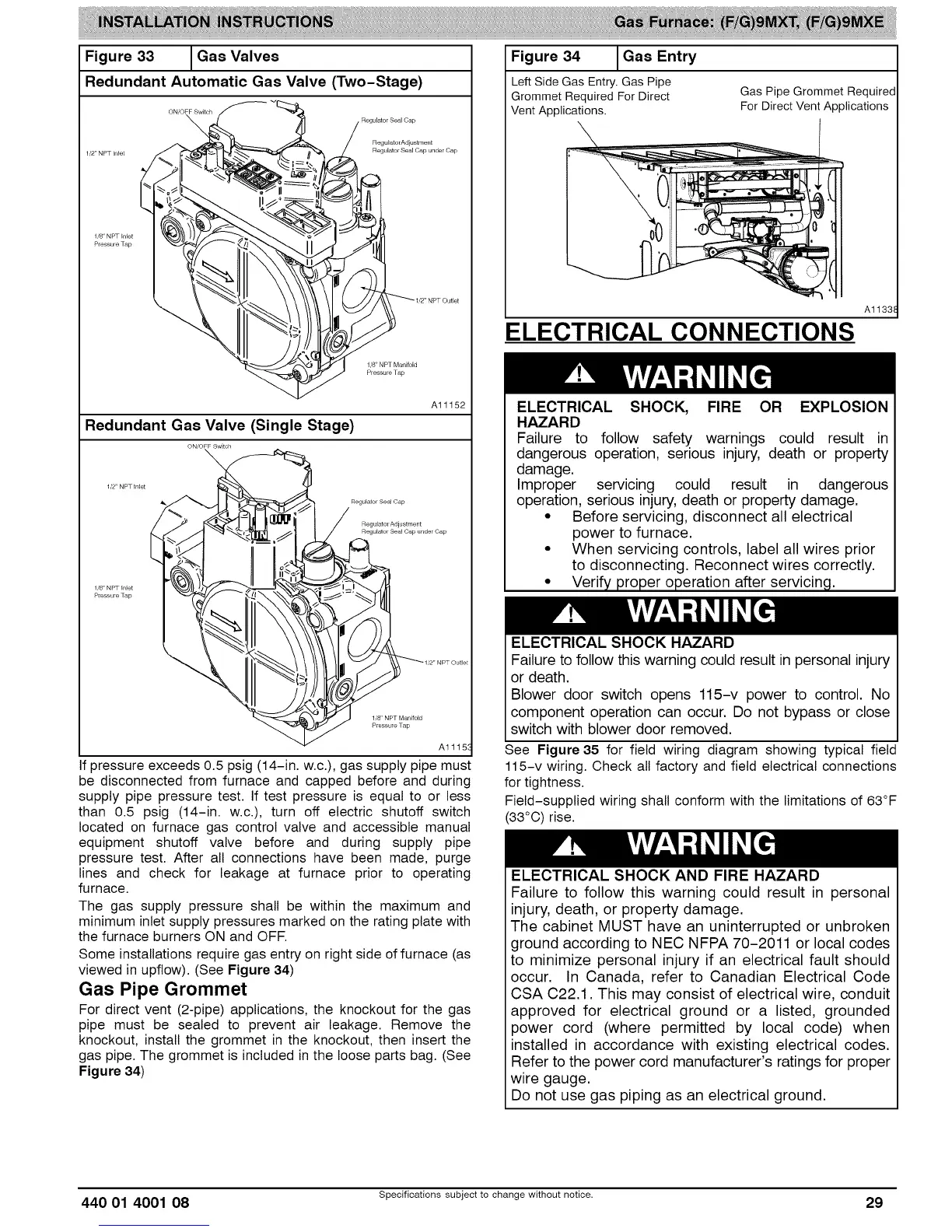

Some installations require gas entry on right side of furnace (as

viewed in upflow). (See Figure 34)

Gas Pipe Grommet

For direct vent (2-pipe) applications, the knockout for the gas

pipe must be sealed to prevent air leakage. Remove the

knockout, install the grommet in the knockout, then insert the

gas pipe.The grommet is included in the loose parts bag. (See

Figure34)

Figure 34 I Gas Entry

Left Side Gas Entry. Gas Pipe

Grommet Required For Direct Gas Pipe Grommet Required

Vent Applications. For Direct Vent Applications

A1133E

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous

operation, serious injury, death or property damage.

• Before servicing, disconnect all electrical

power to furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Blower door switch opens 115-v power to control. No

component operation can occur. Do not bypass or close

switch with blower door removed.

See Figure 35 for field wiring diagram showing typical field

115-v wiring. Check all factory and field electrical connections

fortightness.

Field-supplied wiring shall conform with the limitations of 63°F

(33°C) rise.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

The cabinet MUST have an uninterrupted or unbroken

ground according to NEC NFPA 70-2011 or local codes

to minimize personal injury if an electrical fault should

occur. In Canada, refer to Canadian Electrical Code

CSA C22.1. This may consist of electrical wire, conduit

approved for electrical ground or a listed, grounded

power cord (where permitted by local code) when

installed in accordance with existing electrical codes.

Refer to the power cord manufacturer's ratings for proper

wire gauge.

Do not use gas piping as an electrical ground.

440 01 4001 08 Specifications subject to change without notice. 29

Loading...

Loading...