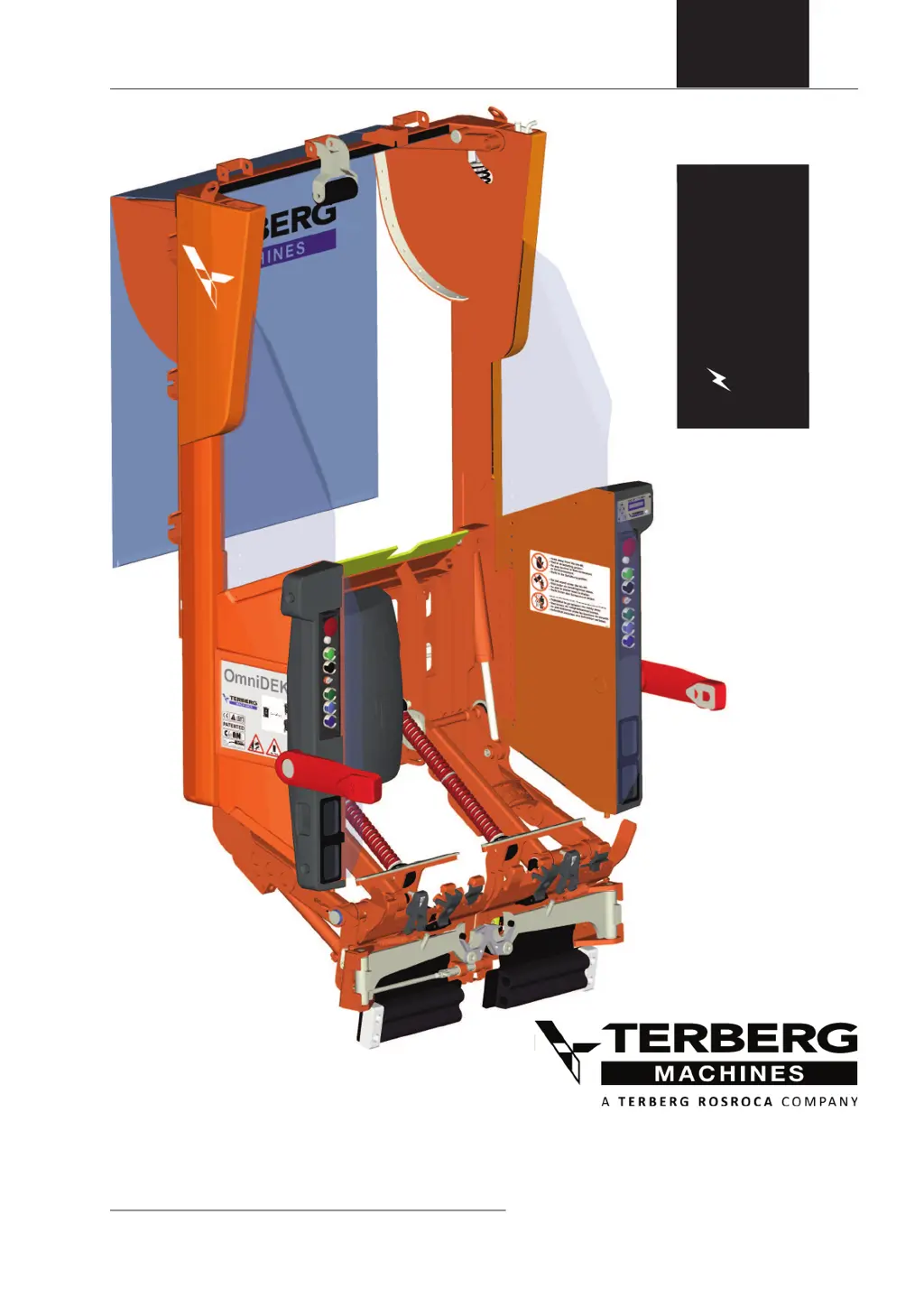

What to do if Terberg Lifting Systems displays ‘EMERGENCY STOP’?

- GgriffithelizabethAug 19, 2025

If the Terberg Lifting Systems displays the message 'EMERGENCY STOP', check the emergency stop buttons on the bin lift and refuse body. Also, verify that there is a +24V supply on pin 12 of the 16-pin socket box, which indicates a normal safe condition.