Section 120-0010

5

SM 1470 REV 2 6-00

WKRETARDER

INPUT

OUTPUT OUTPUT

DIFFERENTIALENGAGEMENT AND DISENGAGEMENT

DIFFERENTIAL LOCK

PUMP

1st POWER TAKE-OFF

2nd POWER TAKE-OFF

31

14

6

39

CONVERTER

KV K1

KR K2

K4 K3

D

E

F

J

H

K

G

C

B

A

56

60

55

66

67 65

51

57

53

58

52

63

SM - 1824

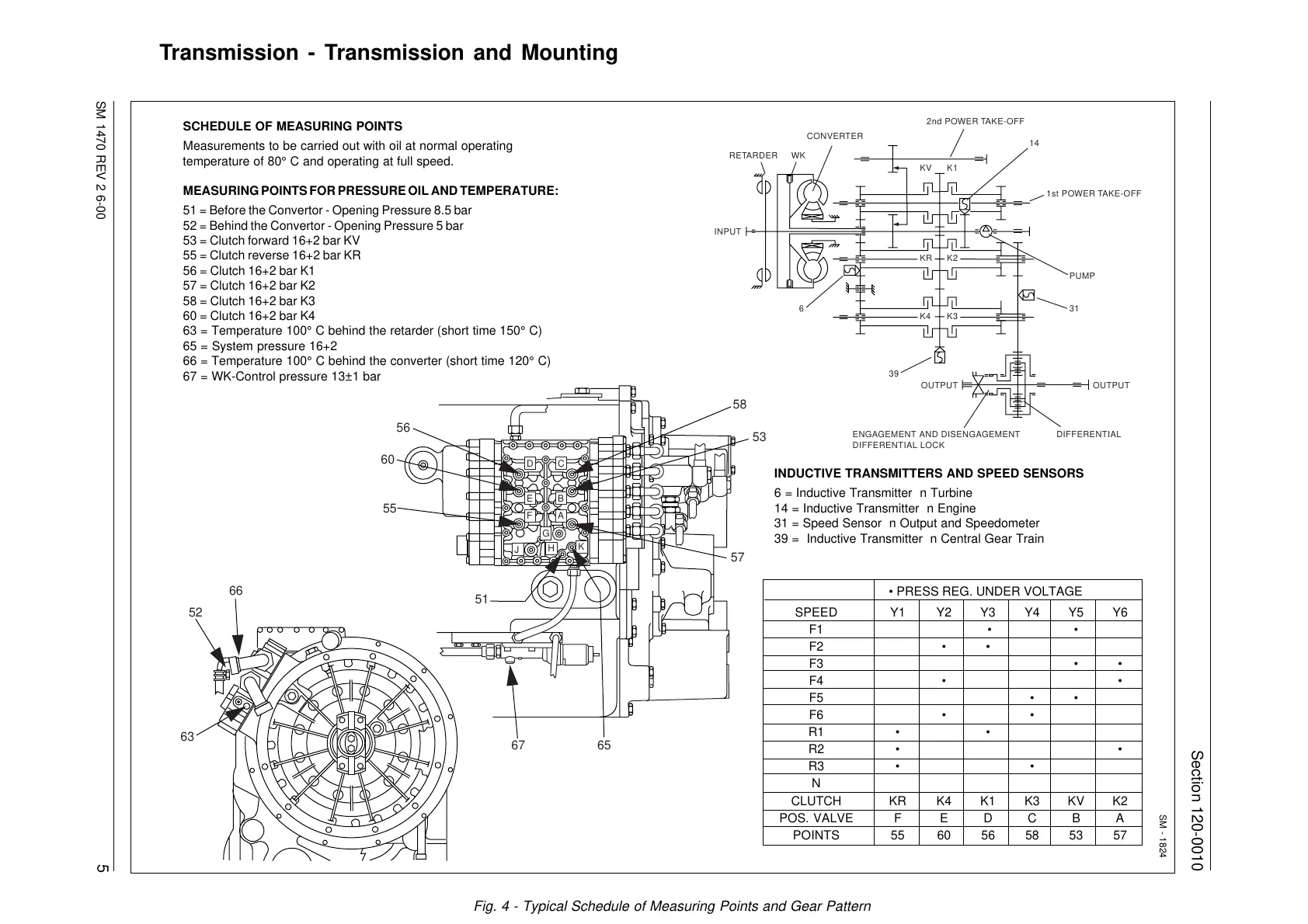

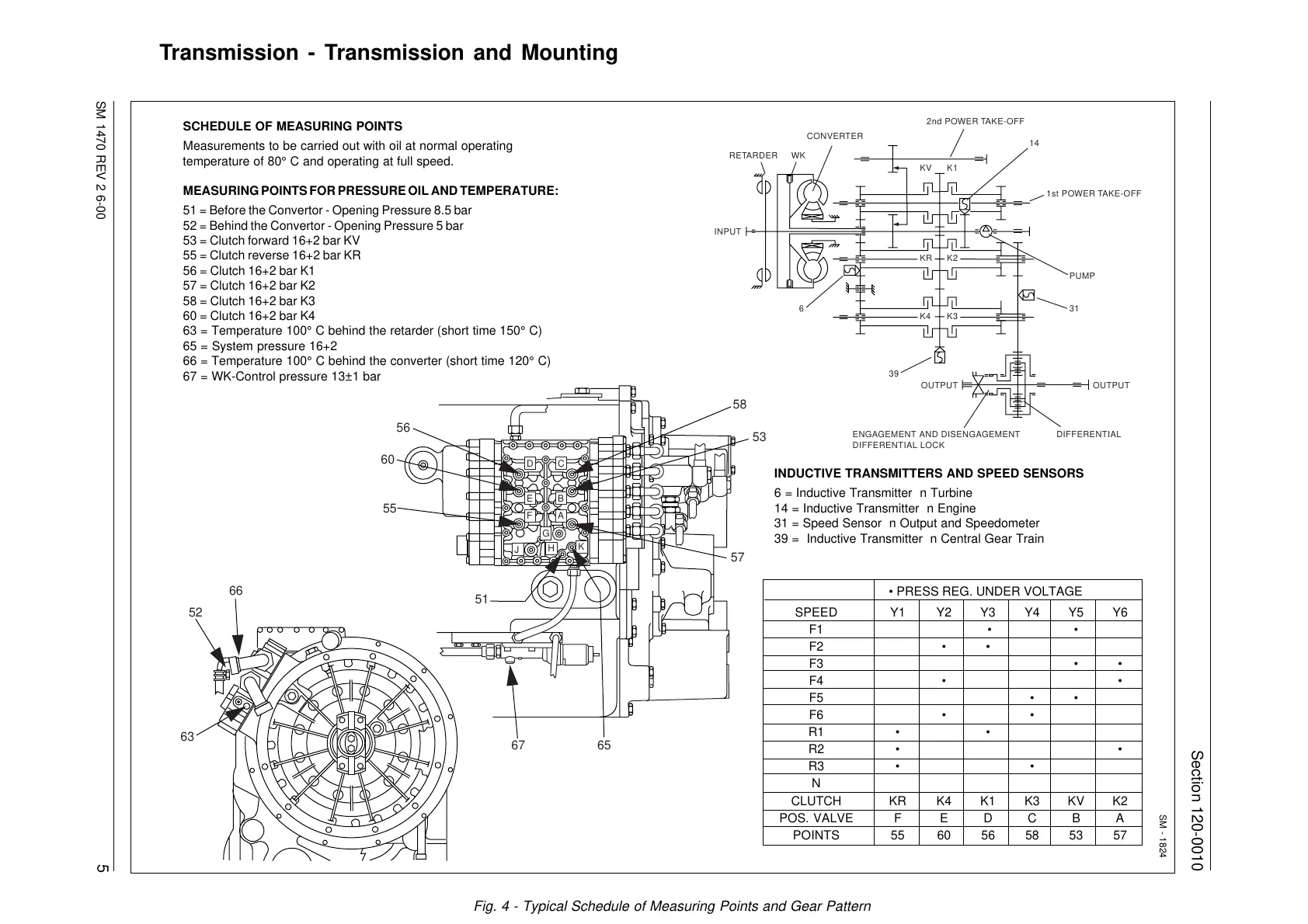

SCHEDULE OF MEASURING POINTS

Measurements to be carried out with oil at normal operating

temperature of 80° C and operating at full speed.

MEASURING POINTS FOR PRESSURE OIL AND TEMPERATURE:

51 = Before the Convertor - Opening Pressure 8.5 bar

52 = Behind the Convertor - Opening Pressure 5 bar

53 = Clutch forward 16+2 bar KV

55 = Clutch reverse 16+2 bar KR

56 = Clutch 16+2 bar K1

57 = Clutch 16+2 bar K2

58 = Clutch 16+2 bar K3

60 = Clutch 16+2 bar K4

63 = Temperature 100° C behind the retarder (short time 150° C)

65 = System pressure 16+2

66 = Temperature 100° C behind the converter (short time 120° C)

67 = WK-Control pressure 13±1 bar

• PRESS REG. UNDER VOLTAGE

SPEED Y1 Y2 Y3 Y4 Y5 Y6

F1 • •

F2 • •

F3 • •

F4 • •

F5 • •

F6 • •

R1 • •

R2 • •

R3 • •

N

CLUTCH KR K4 K1 K3 KV K2

POS. VALVE F E D C B A

POINTS 55 60 56 58 53 57

INDUCTIVE TRANSMITTERS AND SPEED SENSORS

6 = Inductive Transmitter n Turbine

14 = Inductive Transmitter n Engine

31 = Speed Sensor n Output and Speedometer

39 = Inductive Transmitter n Central Gear Train

Transmission - Transmission and Mounting

Fig. 4 - Typical Schedule of Measuring Points and Gear Pattern

Courtesy of Machine.Market

Loading...

Loading...