Section 165-0020

SM 1629 1-99

1

SM - 248

BRAKE PARTS - Brake Parts - Front

DESCRIPTION AND OPERATION

WARNINGS

Use only hydraulic oils meeting specifications

outlined in Section 300-0020, LUBRICATION

SYSTEM. DO NOT use BRAKE FLUID (J1703).

Use of improper fluids is destructive to rubber

components of brakes resulting in loss of

braking and possible catastrophic failure.

Exercise extreme caution while working

on the braking system. The braking system

operates at high pressure.

When servicing wheel brake parts, do not

create dust by grinding or sanding brake pads

or wheel brake parts with a dry brush or

compressed air. A water dampened cloth

should be used for cleaning wheel brake parts.

The service brakes are of the calliper disc-type. The

calliper brake head is designed for use with hydraulic

oils meeting the specifications outlined in Section

300-0020, LUBRICATION SYSTEM. DO NOT USE

BRAKE FLUID (J1703).

The head is bolted to a mounting plate on the spindle.

The disc is bolted to the wheel. There are two brake

heads and a brake disc for each wheel.

Each calliper brake head assembly consists of a

torque plate, two brake pads; one on each side of the

disc and six brake pistons; three on each side of the

disc.

The brake is actuated by hydraulic oil entering the

brake head through one of the bleeder ports. The

piston bores on each side of the torque plate are

interconnected by internal passages.

When the brake is actuated, the hydraulic pressure

forces the pistons against the brake pads which are,

in turn, forced against each side of the brake disc,

slowing or stopping the disc and wheel rotation.

GENERAL INSPECTION

1. Inspect brake pads for wear. If the brake pad

friction material is worn down to 3 mm (0.12 in)

thickness, the pads must be replaced.

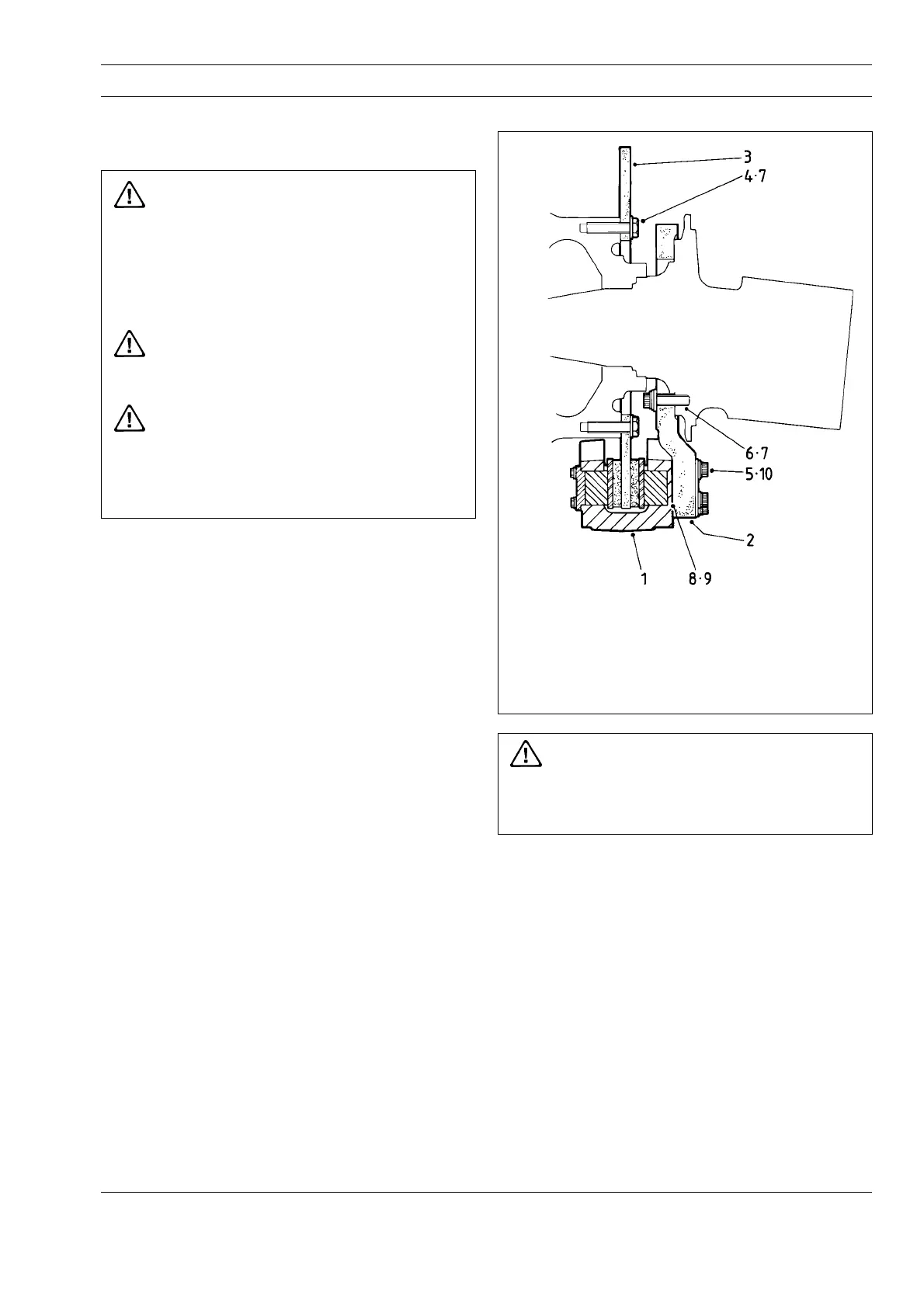

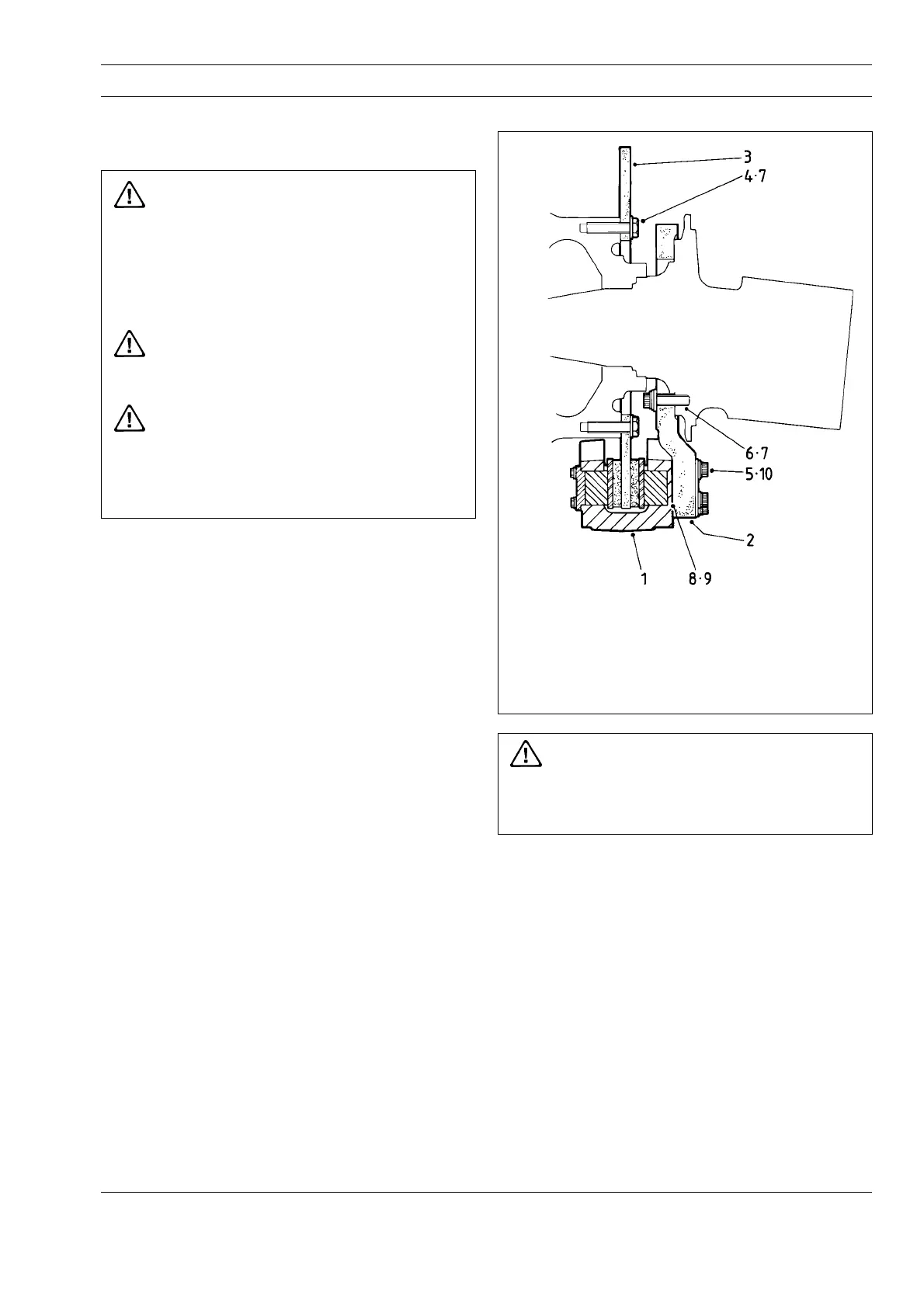

1 - Brake Head Assembly

2 - Front Carrier

3 - Brake Disc

4 - Bolt

5 - Capscrew

6 - Capscrew

7 - Washer

8 - Shim 1.53 mm (0.060 in)

9 - Shim 0.76 mm (0.030 in)

10 - Washer

Fig. 1 - Brake Head and Disc Mounting

WARNING

Failure to replace pads when worn to limits

will result in loss of braking and possible

catastrophic failure.

2. Inspect brake disc for wear. Measure thickness of

brake disc at three points on the brake pad friction

material contact circumference and determine the

average disc thickness.

Note: If the average disc thickness is 22 mm (0.88 in)

or less, the disc must be replaced. Refer to

Section 140-0040, WHEEL, RIM AND TYRE.

Disc Run Out

Maximum acceptable disc run out for disc speeds

lower than 100 rev/min is 0.762 mm (0.030 in) total

indicated reading (T.I.R.). Replace disc or repair hub

if necessary to correct this condition. Refer to

Section 140-0040, WHEEL, RIM AND TYRE.

Loading...

Loading...