9

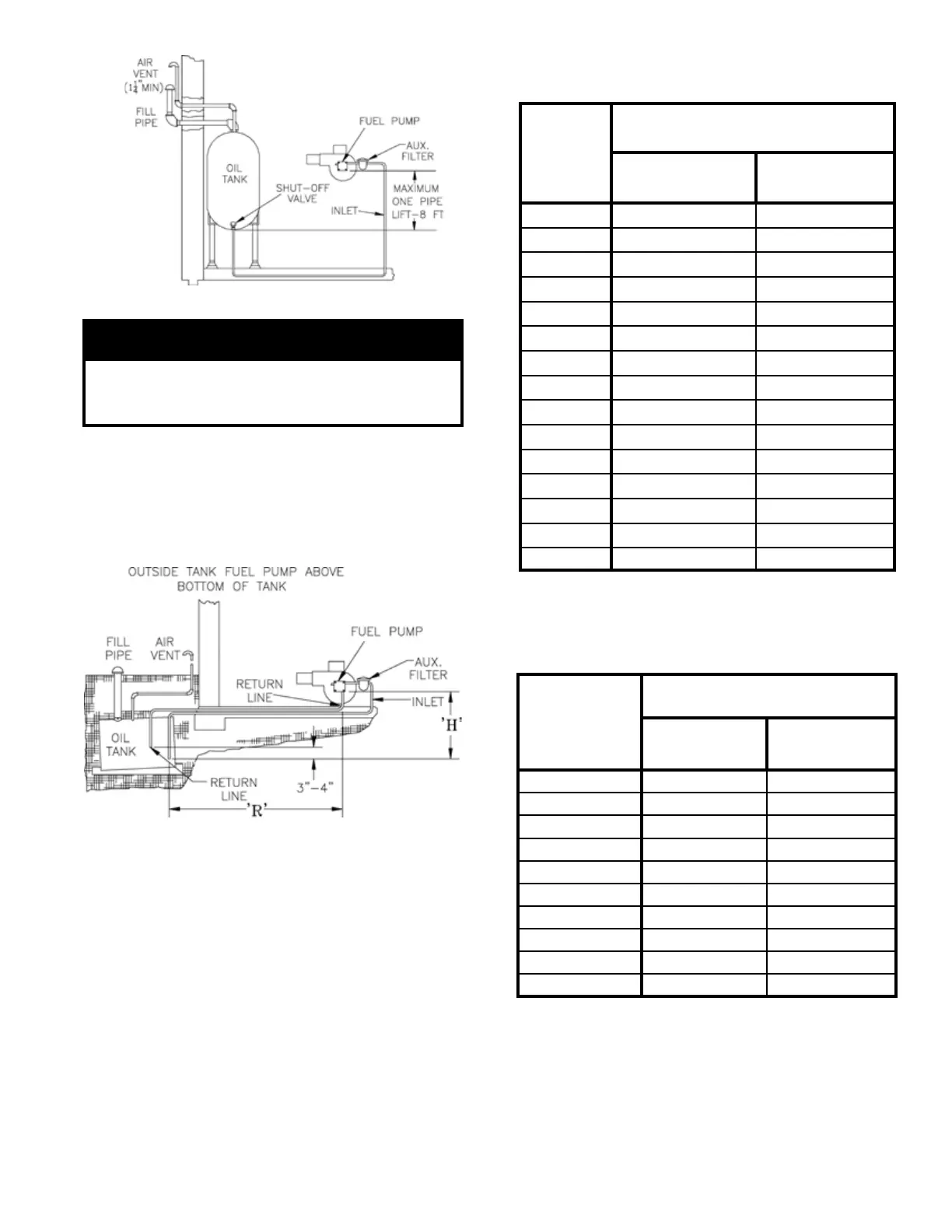

Figure 10

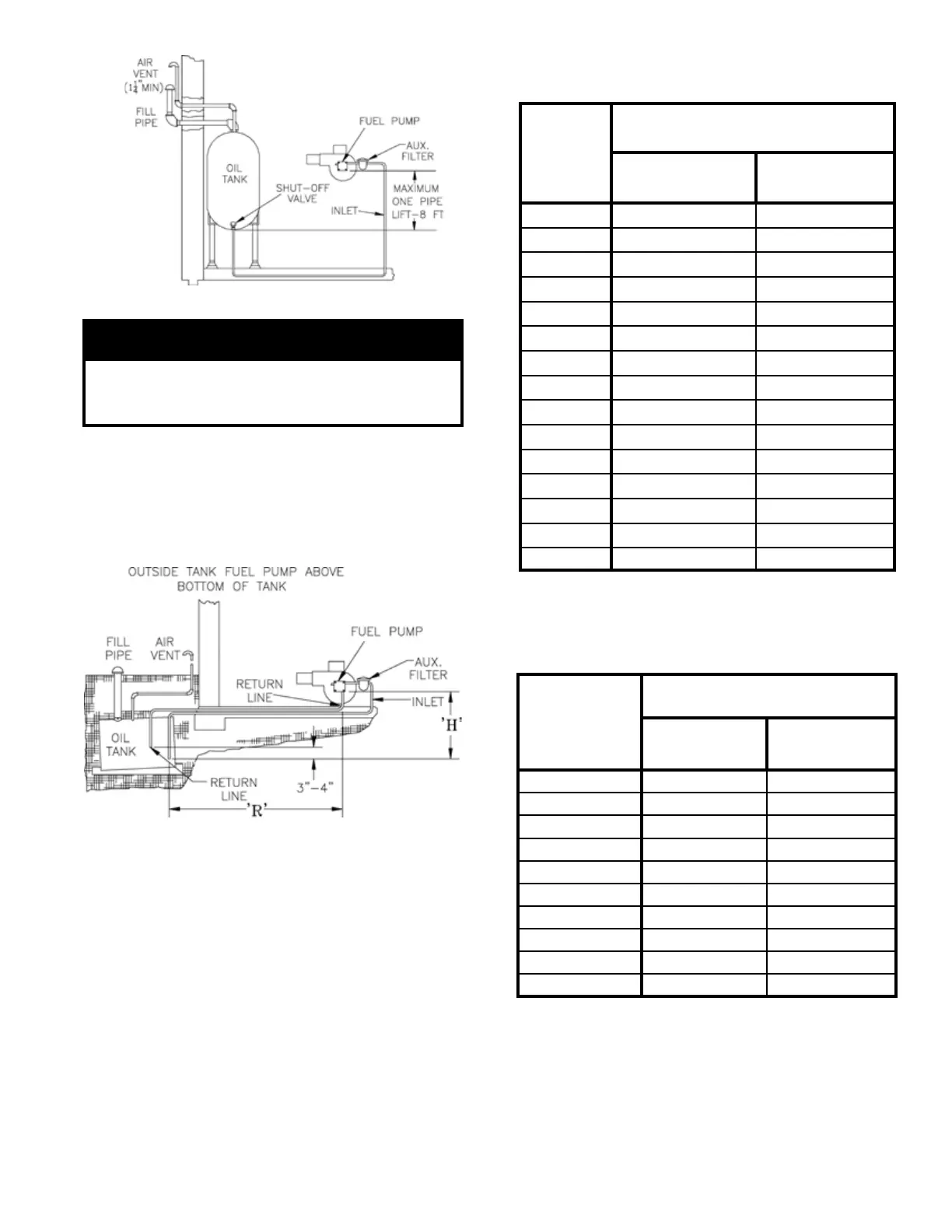

Figure 9

IMPORTANT

Single-pipe installations must be absolutely airtight

or leaks or loss of prime may result. Bleed line and

fuel unit completely.

TWO-PIPE OIL LINES - For two-pipe systems where

more lift is required, the two-stage fuel unit is

recommended. Tables 2 (single-stage) and 3 (two-stage)

show allowable lift and lengths of 3/8-inch and ½-inch

OD tubing for both suction and return lines. Refer to

Figure 10.

Be sure that all oil line connections are absolutely

airtight.

Check all connections and joints. Flared ttings are

recommended. Do not use compression ttings.

Open the air-bleed valve and start the burner. For clean

bleed, slip a 3/16” ID hose over the end of the bleed

valve and bleed into a container. Continue to bleed for

15 seconds after oil is free of air bubbles. Stop burner

and close valve.

Lift "H"

Maximum Length of Tubing

"H" + "R"

3/8" OD

Tubing (3 GPH)

1/2" OD

Tubing (3 GPH)

0' 84' 100'

1' 78' 100'

2' 73' 100'

3' 68' 100'

4' 63' 100'

5' 57' 100'

6' 52' 100'

7' 47' 100'

8' 42' 100'

9' 36' 100'

10' 31' 100'

11' 26' 100'

12' 21' 83'

13' --- 62'

14' --- 41'

TABLE 2: SINGLE-STAGE UNITS (3450 RPM)

TWO-PIPE SYSTEMS

Lift "H"

Maximum Length of Tubing

"H" + "R"

3/8" OD

Tubing (3 GPH)

1/2" OD

Tubing (3 GPH)

0' 93' 100'

2' 85' 100'

4' 77' 100'

6' 69' 100'

8' 60' 100'

10' 52' 100'

12' 44' 100'

14' 36' 100'

16' 27' 100'

18' --- 76'

TABLE 3: TWO-STAGE UNITS (3450 RPM)

TWO-PIPE SYSTEMS

Loading...

Loading...