PULLER-TENSIONER

Model: AFB506

Manual: MI-AFB506-149-00-GB

By moving the levers (table 1, pos. 34-40) to position

(upwards), ropes can be manually strung (without control on the

pull).

ATTENTION: never touch the selectors (table 1, pos. 32-38) while the machine is

working.

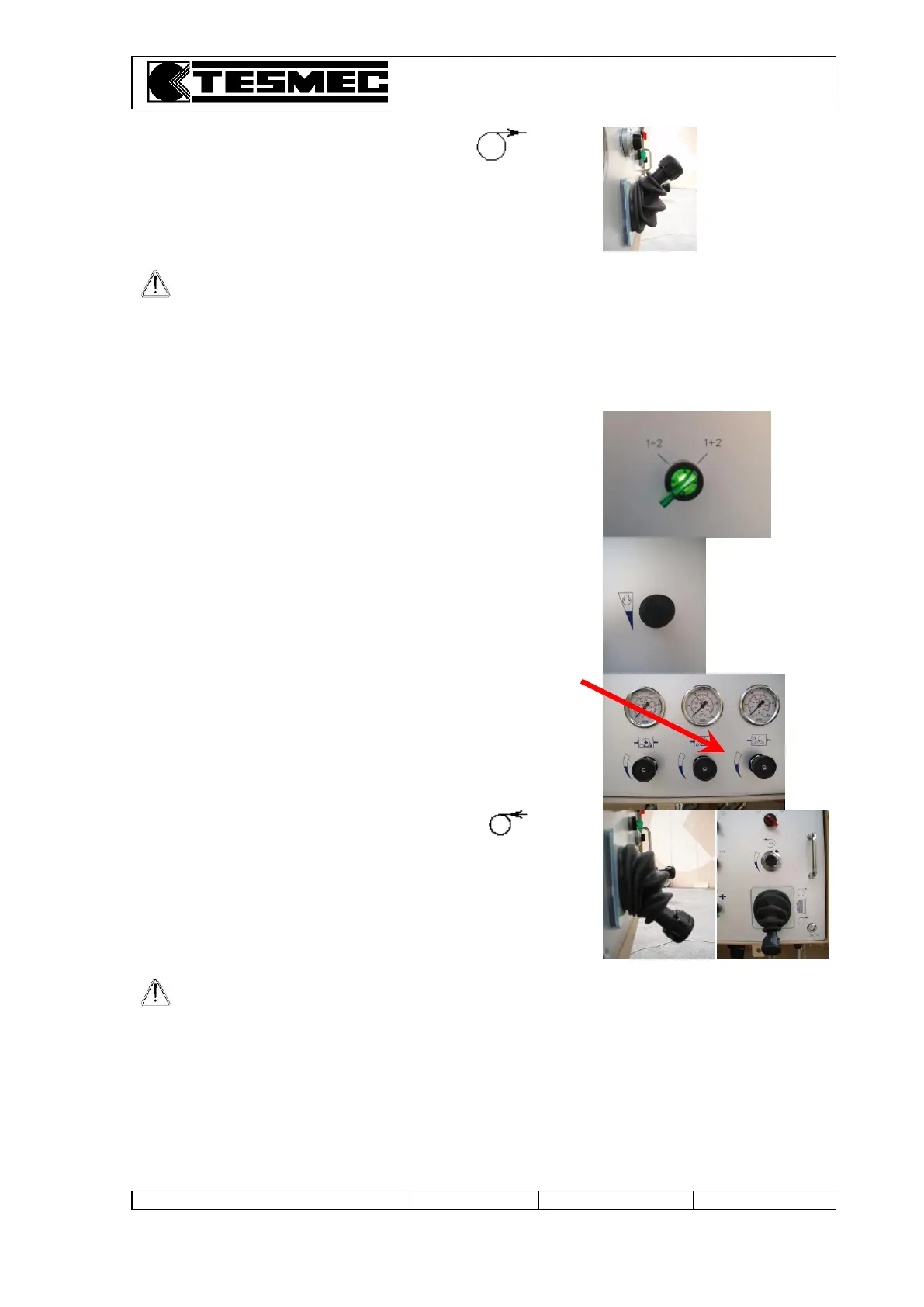

4.11 USE OF THE MACHINE WITH MECHANICALLY CONNECTED BULL-WHEELS (1+2)

a. Check if the coupling pin of the bull-wheels (table 4, pos. 1) is connected.

If not, insert the pin by removing the little covers and using the proper key.

b. Set the selector (table 1, pos. 42) to "CONNECTED

CIRCUITS" position (rightwards).

c. Speed up the Diesel engine by the accelerator (table 1, pos.

18) till a maximum of 2400 rpm.

d. Adjust the hydraulic oil radiator by the valve (table 1, pos. 28).

e. Move the levers (table 1, pos. 34-40) to position

(downwards) to set the pull value on each bull-wheel and the

recovery or release speed of the rope.

NOTE: this way, the bull-wheels 1 and 2 are connected; it is possible to control one

rope with max. pull of 90 kN – 20232 lb or two connected ropes each one with a max.

pull of 45 kN – 10116 lb.

Now the machine is ready for working automatically: each independent circuit can detect if the rope

tension is lower than the pre-set one (therefore it starts recovering) or if it is higher than the pre-set

one (therefore it starts braking while stringing).

Loading...

Loading...