Switching on and off

Switching on/switching off press the key

Setting the zero point

The measurement values can be falsified by a change in the

position of the measuring instrument. After zeroing, the position

of the measuring instrument must not be changed. Carry out

zeroing before every measurement in order to compensate faul-

ty positioning or long-term zero-point drift.

The zero point can be set with the knob located between the pres-

sure connections. Check the zero point before each measure-

ment. Keep ambient temperature.

Measuring range changeover

Press the HI/LO key. The measuring range changes. This is dis-

played by the shifting of the decimal point. Measuring range HI is

operative on switching ON.

HOLD function

By means of the HOLD key, the indicated measured value can be

´frozen´ on the display.

The symbol appears in the display.

Cancel the Hold function by pressing the HOLD key once more.

Battery changing

The appearance of ´BAT´ indicates that the battery capacity is

exhausted.

- Open battery compartment

- Fit 9 V alkali battery (IEC 6LR61) or rechargeable battery

Ensure correct polarity !

Dispose of the used battery correctly and according to environ-

mental regulations.

Specifications

Technical data

Measuring media Instrument air or inert gases

Units mbar

(other units available on request)

Linearity, hysteresis and ± 0,2 % F.S. ± 1 Digit

repetition accuracy (measuring range HI)

± 0,5 % F.S. ± 1 Digit

(measuring range LO)

Reference temperature 22 °C

Temperature influence ± 0,05%/°C

Operating temperature 0 °C to +60 °C

Storage temperature -30 °C to +85 °C

Case protection class IP 54

Power supply 9 V block battery or rechargeable

battery IEC 6LR61

Current consumption approx.1.7 mA

Battery life approx. 250 h

Measuring rate 3 measurements / s

Display 3 1/2 digit LCD with sign

12.7 mm high

HOLD indication

LO BAT indication

Pneum. connection Hose 4/6 mm, NPT 1/8 ”

Case dimensions 152x83x34/29 mm

Weight incl. battery 250 g

* measuring ranges in bar

d = differential pressure g = relative pressure

1) max. static pressure = 7 bar

2) max. static pressure = 27 bar

Conversion factors

1 mbar = 0.1 kPa 1 mbar = 0.0145 psi

1 mbar = 1 hPa 1 mbar = 0.4015 inH2O

1 mbar = 0.0010 bar 1 mbar = 0.02953 inHg

1 mbar = 10.20 mmH2O 1 mbar = 0.7501 mmHg

Maintenance

testo 520 does not require any maintenance. It can be cleaned

with a damp cloth. Do not use cleaning agents containing solvents

!

You are recommended to have the instrument recalibrated by the

supplier at least once per year.

Fault

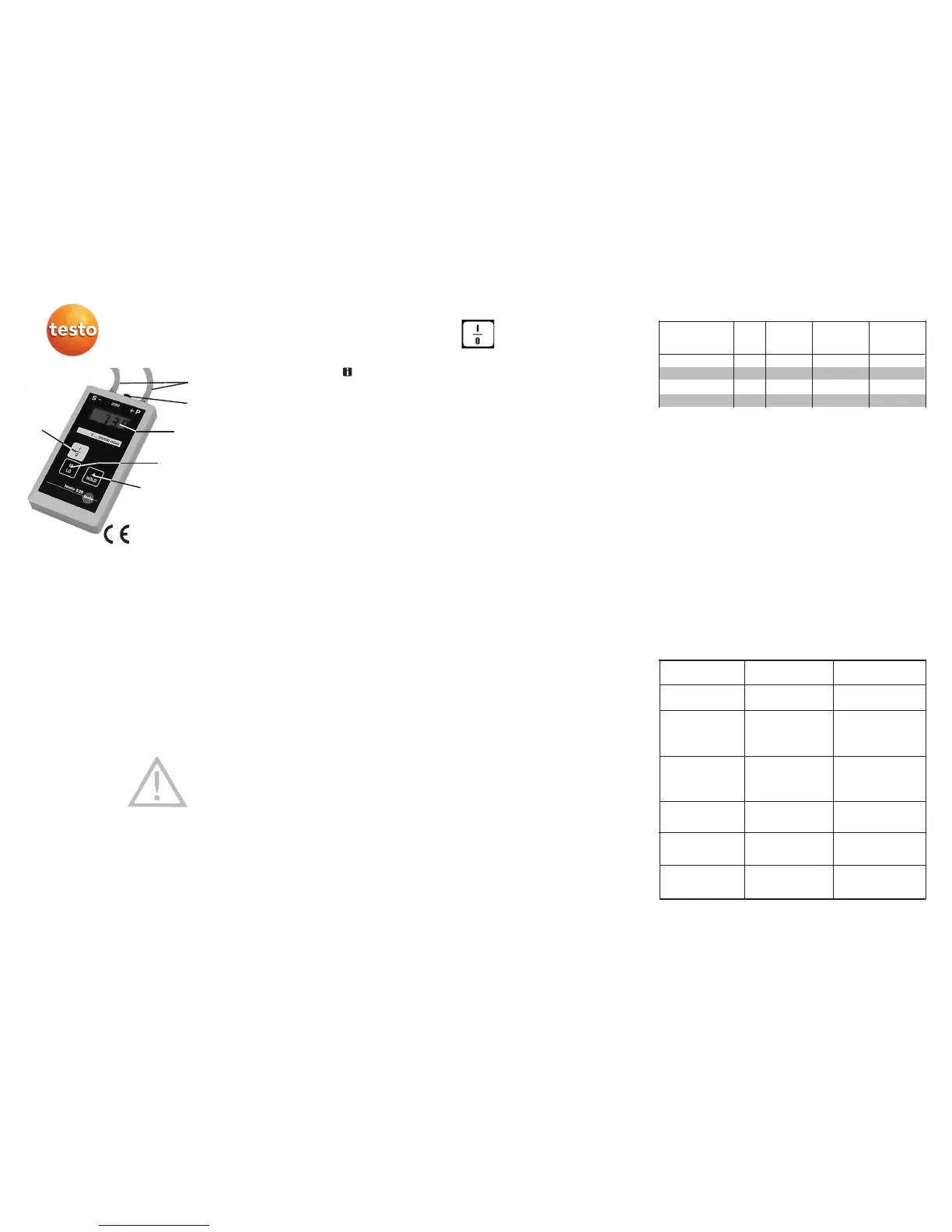

Measuring ranges

Fault/ Possible Remedy

Indication Cause

BAT Battery voltage Fit new battery

under 7.3 V

No indication Battery discharged Fit new battery

Battery not Check

correctly installed

Instrument Sensor ageing Recalibrate

inaccurate

Zero point not set Set zero point

Indicated value Excess pressure Dispatch

does not change applied to instrument for

pressure sensor repair

Erroneous mea- Battery discharged Fit new battery

sured value and

simultaneously BAT

1_ _ _ Display range Set permissible

exceeded measured value or

measuring range

Measuring range

(mbar) LO/HI

Type of

pressure

max. loading

capability(mbar)

Resolution

LO/HI

max. display

LO/HI

testo 520

Digital handheld pressure gauge

Description

The Testo handheld pressure gauge testo 520 is a digital pressure

measuring instrument with integrated pressure sensor for the mea-

surement of differential or relative pressures. Its 3 1/2 digit LCD

display and high precision render it suitable for a wide range of

applications.

Features

- Piezo-resistive pressure sensor

- Measuring range HI, class 0.2% F.S.

- Measuring range LO, class 0.5% F.S.

- For instrument air or non-corrosive gases

- measuring range changeover

- Large LCD display

- HOLD function

- Zero point setting

- Lo-Batt indication for battery change

- Facility for 9 V block battery or rechargeable battery

- Splash-proof ABS case (IP 54)

24 month warranty

Safety details

The pressure values in these operating instructions should not

be exceeded or the pressure sensor can be destroyed.

The instrument is not to be used in an explosive environment !

Ensure correct connection of the pneumatic hoses !

Operating

Pneumatic connections

Before making the pneumatic connection to the instrument, ensure

that no pressures can occur in the system which could exceed the

maximum overload capacity of the testo 520. The connections are

intended for direct connection to the measuring pipelines (hose,

internal diameter 4 mm, external diameter

6 mm). The 0 to 1/10 bar measuring range is always fitted with

NPT 1/8” connection unions.

P + higher pressure

- S lower pressure

Measuring instrument conform to EC directive

2004/108/EEC. The instruments were tested in the

frequency range of 27 - 500 MHz. The specified

parameters cannot be guaranteed in the named

frquency range.

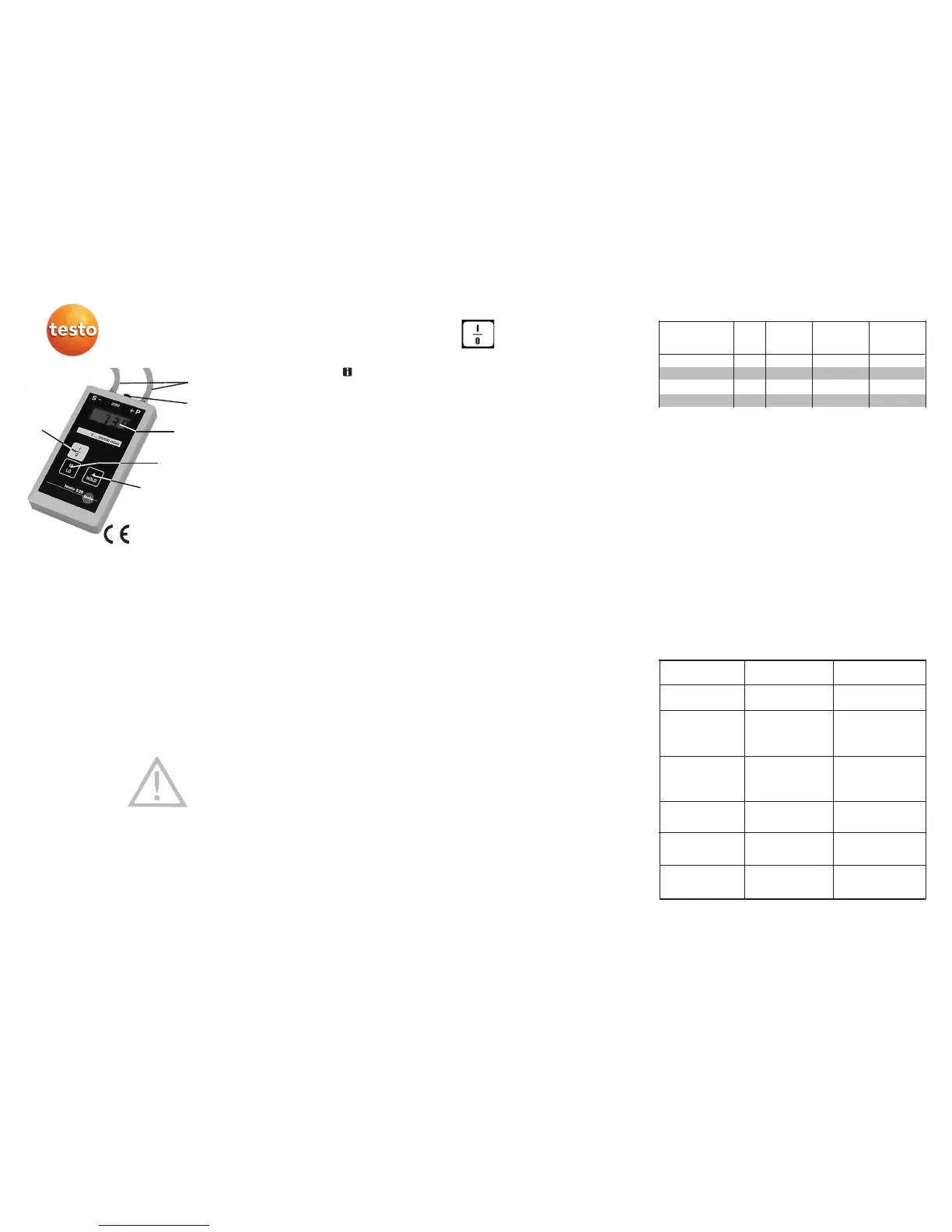

On/Off

Higher/lower

measuring range

Freeze display

3 1/2 digit LCD display

Connection for pneu-

matic hoses 4/6 mm

Zero point setting

Operating instructions

0 to 20.00/200.0

1)

d,g 0.01/0.1 19.99/199.9 1500

0 to 100.0/1000

1)

d,g 0.1/1 199.9/1999 2000

0 to 200.0/2000

1)

d,g 0.1/1 199.9/1999 3000

0 to 1.000/10.00*

2)

d,g 0.001/0.01 1.999/19.99 27000

Loading...

Loading...