15

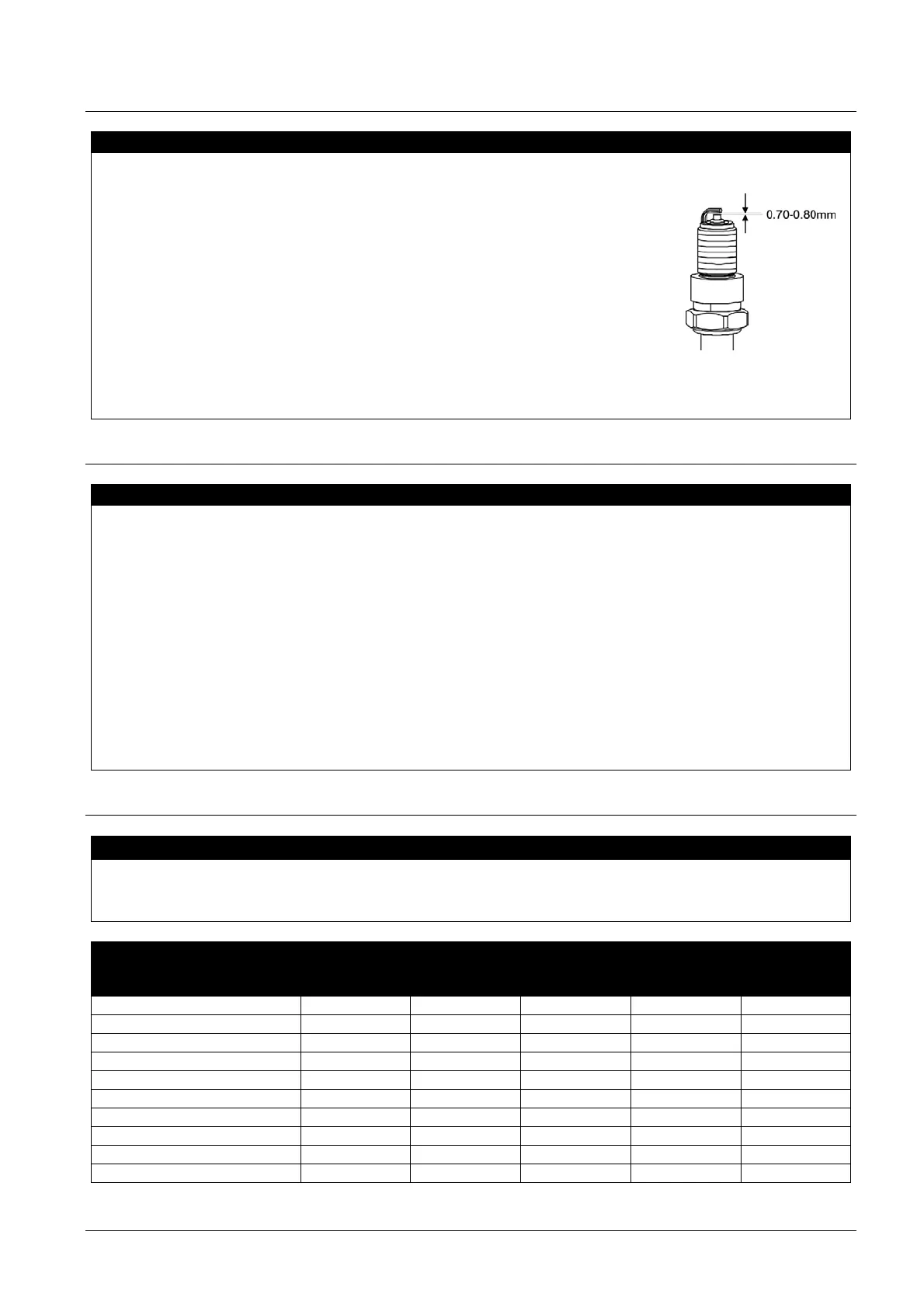

8. Sparking plug

PROCEDURE

• Remove the sparking plug cover.

• Brush off dirt from the sparking plug.

• Use a sparking-plug wrench to loosen the sparking plug.

• Inspect if the isolation is intact.

• Clean the sparking plug with a steel brush.

• Measure the electrode distance; make sure not to damage the

electrode.

• The distance should be: 0,7 – 0,8 mm

• If the sparking plug is okay, put it back in its place.

• Put the sparking plug cover back in its place.

Note: The engine must be cold

9. Transport and storage

TRANSPORT AND STORAGE

Transport

• To avoid any spillage of fuel and oil is it important that the engine is placed horizontal

during transport.

Storage

• Let the engine run till it stops.

• Loosen the drain screw on the carburettor and drain the remaining fuel.

• Reinstall the drain screw and mount the fuel tube.

• Keep the old fuel in an approved container.

• Remove the sparkplug and poor 1 tablespoon of oil into the cylinder, mount the sparkplug.

• Do not mount the sparkplug cap. Pull the sparking cord, until there is resistance. This will

close the valves and protect them from rust.

• Protect the oil with a thin layer of oil to avoid rust.

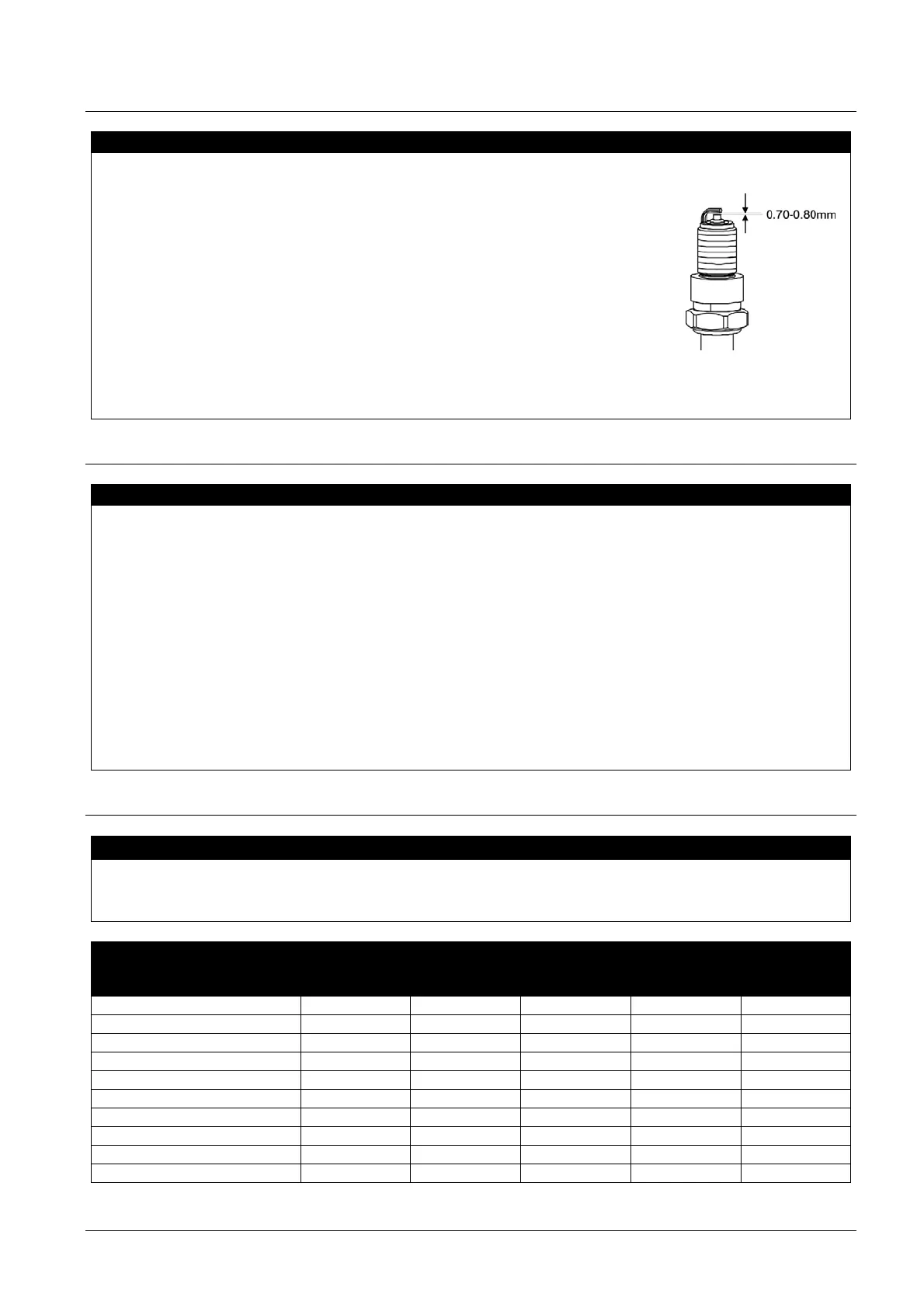

10. Maintenance

NOTE

• The purpose of maintenance is to keep the engine in its best possible shape.

• Repairs must always be carried through by an authorized dealer.

Interval

Part

Every time

For every

20 running

hrs

For every

50 running

hrs

For every

100 running

hrs

For every

200 running

hrs

Inspect bolts and nuts X

Inspect and fill with oil X

Chan

e oil X

Inspect for oil leaka

e X

Inspect air filte

X

Clean air filte

X*

Clean fuel filte

X

Inspect sparkin

plu

X

Ad

ust valves X

Inspect valves X

* Maintenance of air filter in accordance with the user manual to the machine where the engine is

mounted.

Loading...

Loading...