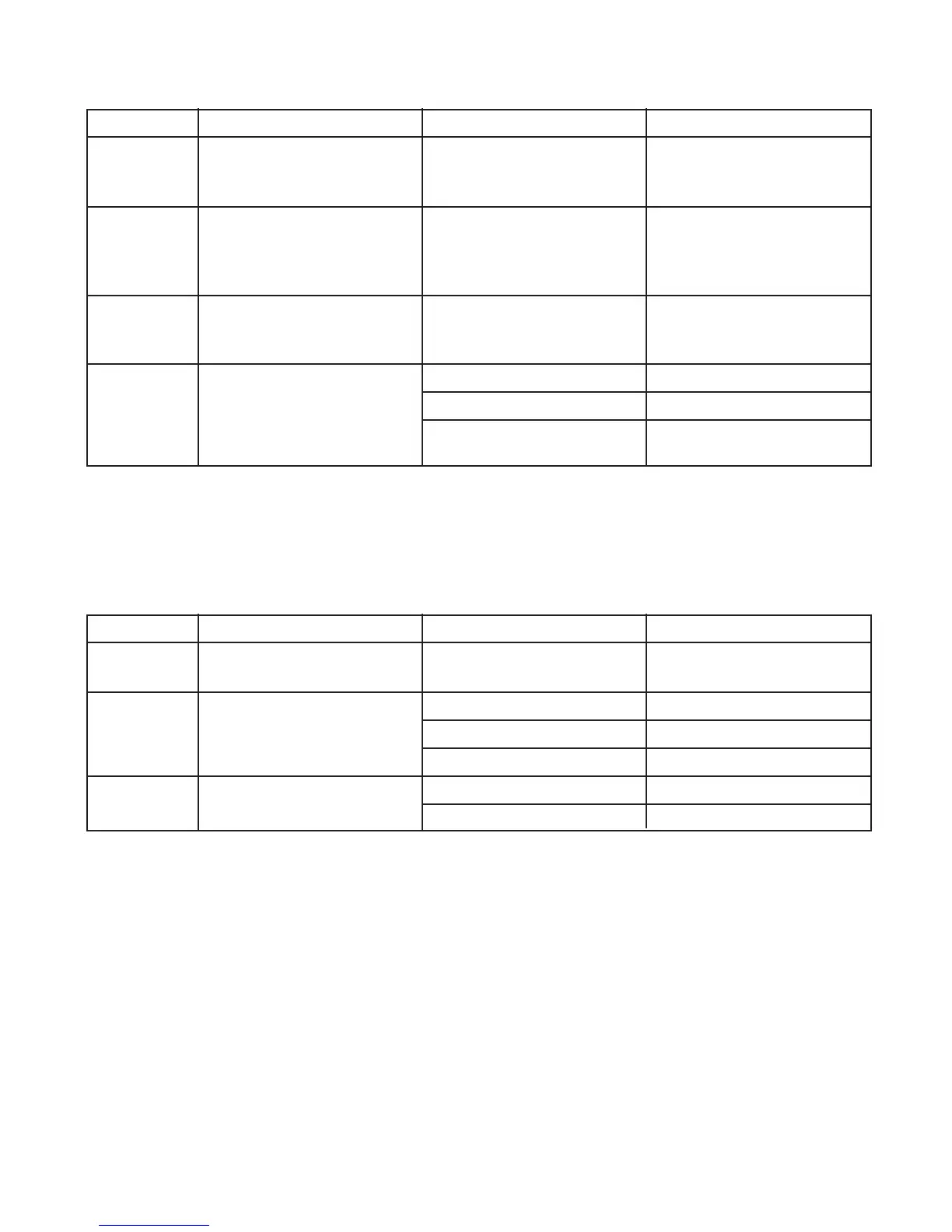

19

Cad Cell Check cad cell with ohmmeter. If

more than 2000 ohms, cad cell is

defective or dirty.

Primary After burner fires, open cad cell

Control circuit if flame looks OK. If

burner continues to operate, fault

is in primary control.

Heat Inspect heat exchanger.

Exchanger

Restriction

Burner Burner motor trips on overload.

Motor Turn off power and rotate blower

by hand to check for excessive

drag.

Faulty or dirty cad cell

Faulty primary control

Plugged heat exchanger.

Line voltage below 120V

Faulty motor.

Pump or blower overloading

motor.

Clean or replace cad cell.

Replace primary control.

Clean out heat exchanger.

Call utility company.

Replace motor.

Replace blower or pump.

S

OURCE PROCEDURE CAUSES REMEDY

TROUBLE: BURNER FIRES, BUT THEN FAILS ON SAFETY

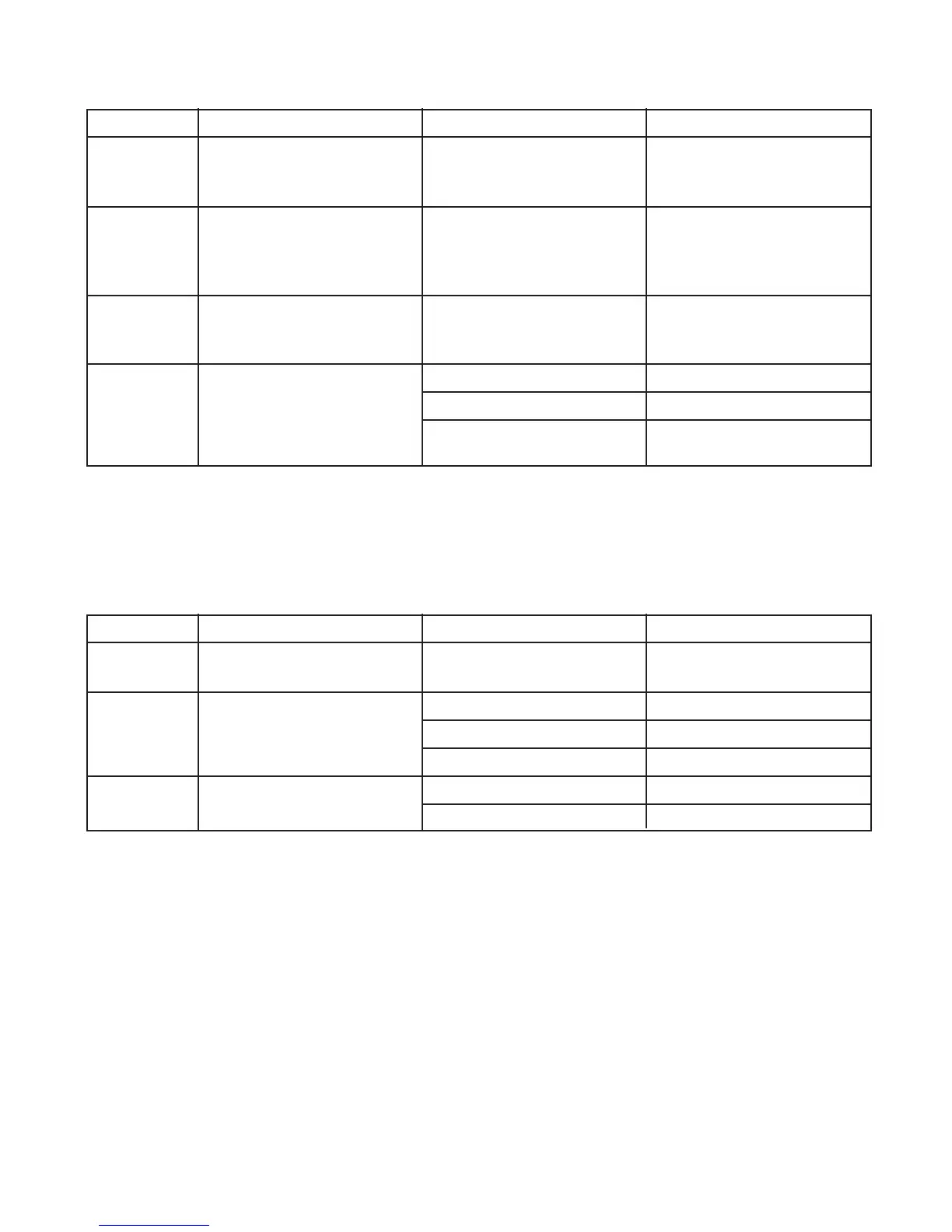

Circulator Check to see if operating control

is working properly.

Thermostat Check thermostat settings and

calibration.

Flow Valve Check to see if flow valve is

operating properly.

Circulator does not stop

running.

Thermostat set too high.

Thermostat defective

Thermostat out of calibration.

Flow valve dirty and stuck.

Flow valve defective.

Repair operating control.

Reset thermostat.

Replace thermostat.

Recalibrate. Check level.

Clean flow valve.

Replace flow valve.

SOURCE PROCEDURE CAUSES REMEDY

TROUBLE: TOO MUCH HEAT

When checking burner adjustments always use instruments.

Loading...

Loading...