TA02982 E page 3 of 8

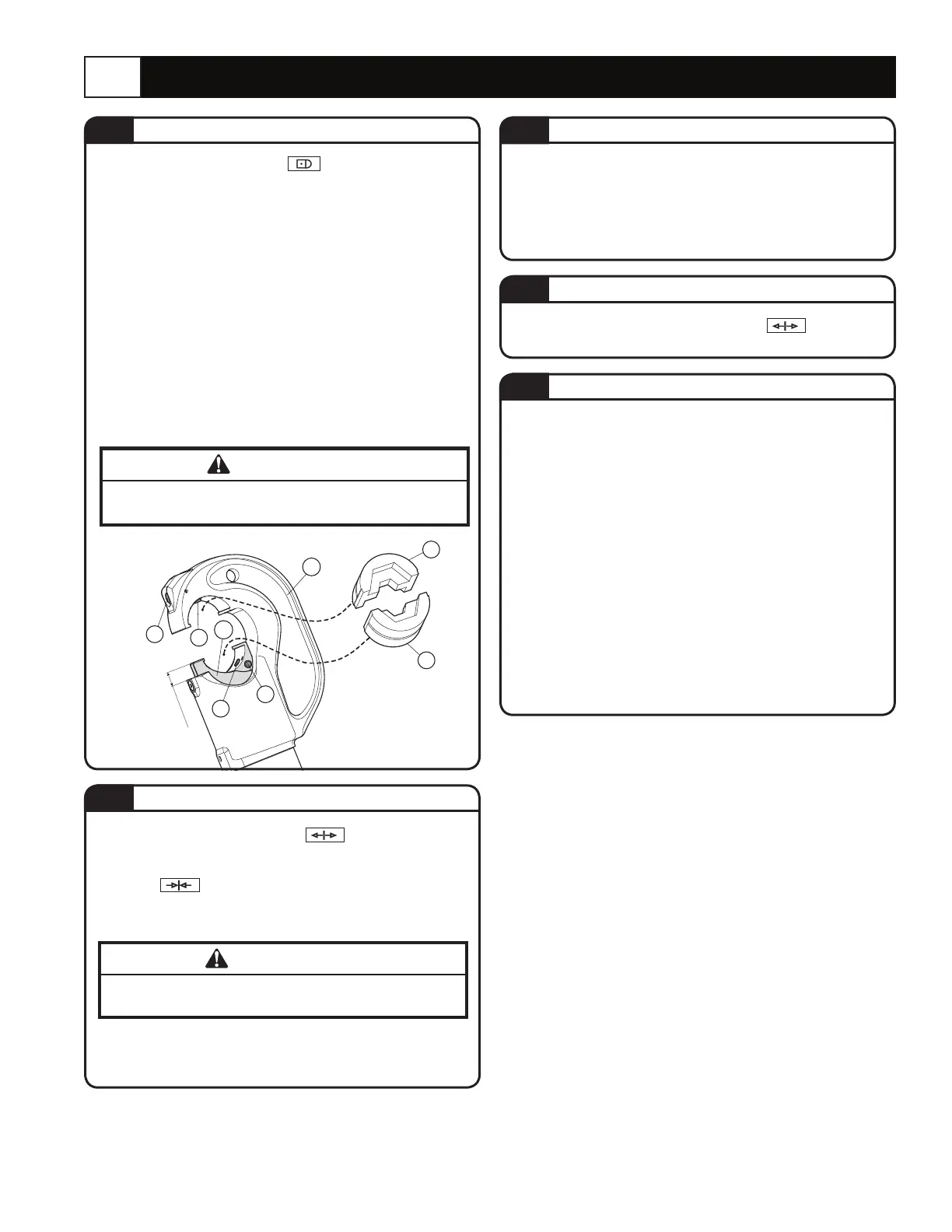

30

36

202

32

201

37

~ 8 ÷ 10 mm

(0.3 - 0.4 in.

)

90

91

− Set the tool in the release position by rotating the xed

handle (200). The moveable handle (203) will be released and

the main handle will rotate automatically to the operating

position .

− Operate moveable handle (203) for lower die advancement.

This rst stage rapidly closes the dies to the connector.

To replace dies proceed as follows: (Refer to Figure 2)

Upper die (91)

− Take the die off its guide by pushing the die/head release

pin (30).

− Insert replacement die until secured by the die/head retaining

pin (32).

Lower die (90)

− Take the die off its guide by pushing the die/head release

pin (36).

− Insert replacement die until secured by the die/ram retaining

pin (37). To facilitate this operation an advancement of the ram

by 8-10 mm (0.3 - 0.4 in.) is suggested.

− Continue operating the movable handle (203). The tool will

automatically change over to the high pressure stage. The ram

will advance until the dies meet.

− Continue pumping until the maximum pressure valve is

activated and a “click” is heard.

− Rotate the xed handle to release position

Close

handles. The ram will then retract, and the dies will open.

Make sure the dies are exactly positioned on desired crimp point,

otherwise re-open dies following instructions as per 2.4 and

reposition the connector.

DIE ADVANCEMENT

DIE REPLACEMENT

COMPRESSION

RELEASE OF DIES

WARNING

Never place the tool under pressure without inserting the

dies, this could cause damage to the head and the ram.

2.0 INSTRUCTION FOR USE

With the tool in the rest position prepare the tool as

follows: (see Figure 2)

− Select the appropriate die set for the connector.

− Insert the die (91) in the upper seat of the tool head until it is

locked by die/head pin (32). To ease the die insertion, keep

die/head release pin (30) depressed.

− Operate the tool (per 2.2) to advance the ram (202) 8-10 mm

(0.3 - 0.4 in.) and insert the die (90) into the seat on the ram

until it is locked by die/ram retaining pin (37). To ease this

operation, keep die/ram release pin (36) depressed.

− Insert the conductor in the connector.

− Position the connector between the dies and ensure the

correct location of the crimp.

− For ease of operation, the tool head can rotate through 180°.

PREPARATION

FIGURE 2

2.1

2.2

2.5

2.3

2.4

WARNING

DO NOT ATTEMPT TO TURN THE HEAD IF THE

HYDRAULIC CIRCUIT IS PRESSURISED.

Loading...

Loading...