6

HOW TO DISASSEMBLE FOR CLEANING AND REPAIR

SERVICE HINTS

The model "HL" carburetor can be cleaned under adverse

conditions - working on a clean surface with a minimum of

tools. Before disassembling carburetor it is IMPERATIVE

to flush it clean of sawdust and dirt by pouring gasoline

over it and tools.

1. Remove strainer cover retaining screw and plastic

cover.

2. Remove strainer cover gasket and strainer screen.

3. Remove screws and fuel pump body.

4. Remove fuel pump diaphragm and gasket.

5. Remove main diaphragm cover plate.

6. Remove main diaphragm.

7. Remove main diaphragm gasket.

8. Remove inlet control lever fulcrum pin, lever and

tension spring.

9. Remove inlet needle.

10. With a thin wall 5/16" Hex socket carefully remove the

inlet seat. Remove inlet seat gasket. When

reinstalling seat, tighten only from 25-35 inch-pounds

or 34Kg-Cm.

1. Remove idle and main adjustment screws.

2. When reinstalling "O" ring type adjustment screws,

lubricate with #30 SAE oil to prevent seizing. Packing

spring type adjustments to not require lubrication.

3. The ball check type main nozzle can be removed by

tapping it out of the body casting into the venturi with a

small punch. A replacement ball check nozzle should

be pressed into the casting with the cross holes in line

with the main adjustment needle. The brass cage

should be pressed flush with the metering chamber

casting.

Before reassembling the carburetor (in reverse order as

outlined above), wash ALL component parts in clean

gasoline and blow off with compressed air. The channels

in the metering body should be cleaned by blowing through

the idle and main adjusting orifices.

All fuel passages in the three castings should be cleaned

with compressed air. Do not clean orifices or passages

with wires or drills as this might cause damage and

incorrect operation of the carburetor.

CAUTION:

Under extreme conditions of clogged idle fuel

supply channel and discharge ports, it may be necessary to

remove the channel welch plug. If so, it must be very carefully

done in following manner:

1. Drill a 1/8 " diameter hole through the 3/8” diameter welch

plug. This hole should just break through the welch plug.

Depper drilling will seriously damage the body casting and

its discharge ports located close behind the welch plug. On

some models an

additional smaller 1/4 " diameter channel

welch plug is used. It is not necessary to remove this plug.

2. Carefully pry out welch plug, then clean discharge ports

and cross channels. Now install new

part 02531 (3/8"

diameter, 1/32" thick) welch plug by placing it in casting

shoulder, convexed side upward; then flatten to a tight fit

with a 5/16" diameter flat end tool.

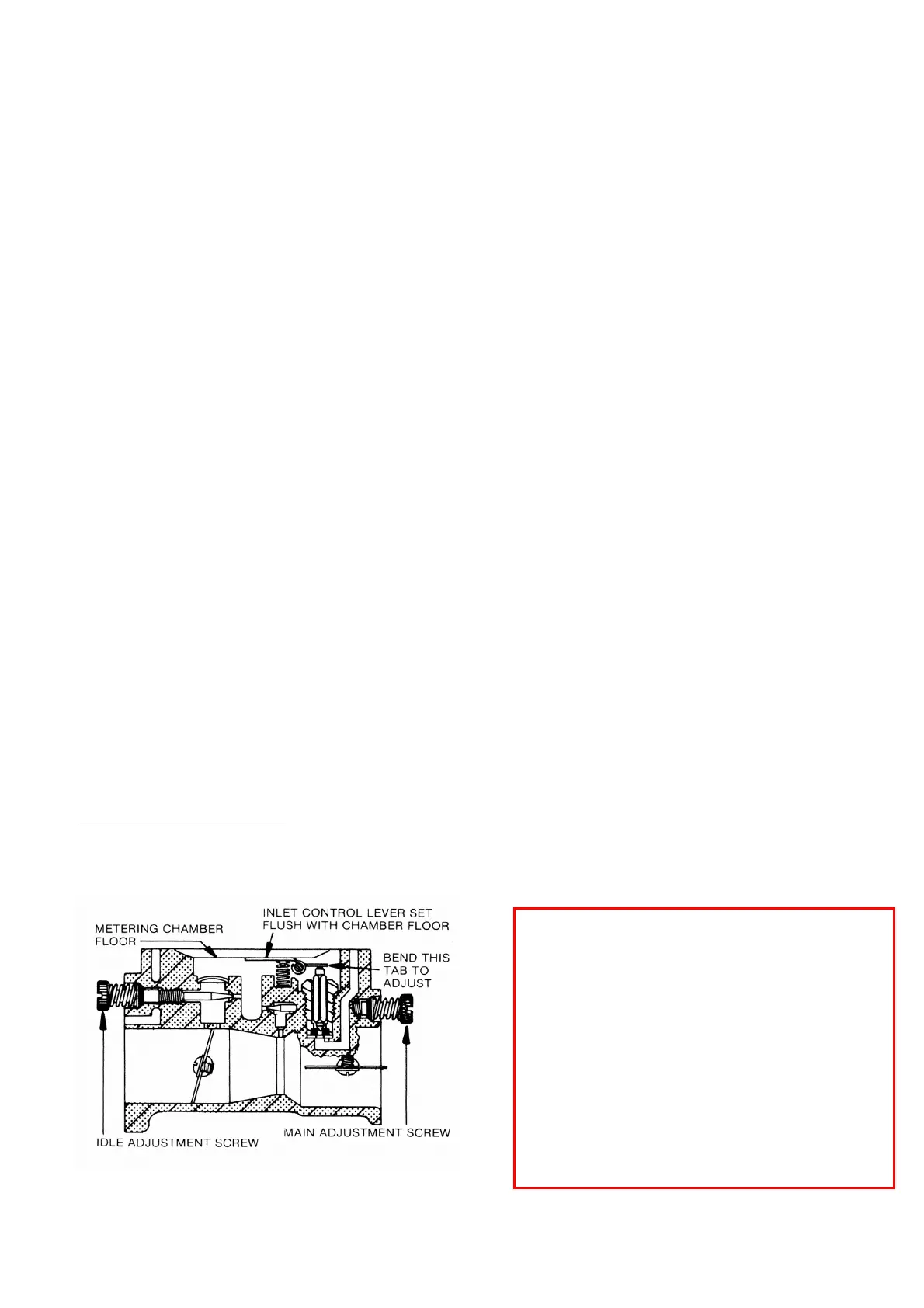

When reassembling the inlet control lever and spring,

care should be taken to see that the spring rests in the

well of the metering body and locates on the dimple of the

inlet control lever, (as illustrated below).

CAUTION: Do not stretch spring.

Inlet control lever is properly set when flush with floor of

diaphragm chamber.

Be certain main diaphragm, gasket and cover casting are

carefully fitted over the three small pins cast in rim at bottom of

metering body; also the fuel pump gasket, diaphragm and fuel

pump body, over similar pins at bottom rim of main

diaphragm

cover casting. Evenly tighten fuel pump body retaining screws

to insure complete seal of casting separations at both

diaphragms.

Frequent cleaning or replacement of fuel strainer screen will

aid satisfactory operation of the carburetor.

Loading...

Loading...