2

The demand for a miniature all position diaphragm

carburetor prompted Tillotson to design and develop

the “HS” series. This small compact unit, only a 1-1/2

inch cube, is versatile in application because of its

lightweight and compact size. Even though the

carburetor is extremely minute, it still comprises a

self-contained fuel pump and filtering screen.

The “HS” series carburetor is die-cast aluminium,

consisting of three basic parts: metering body, pump

cover plate and main diaphragm cover plate. This

carburetor incorporates many of the components

found in float type carburetors: choke, throttle, idle

and high speed mixture screw and inlet needle.

Information contained in the following pages is

presented as an aid to understanding construction,

operation and servicing of the “HS” series carburetor.

Complete carburetors, repair kits and service parts

are available through our dealers.

Idle and high speed mixture screws are spring friction

type and require no packing. These mixture screws

are located on the right side looking toward air horn.

A rubber tipped needle seats directly on a machined

orifice in the body casting. An inlet tension spring

CONSTRUCTION DATA AND CHART

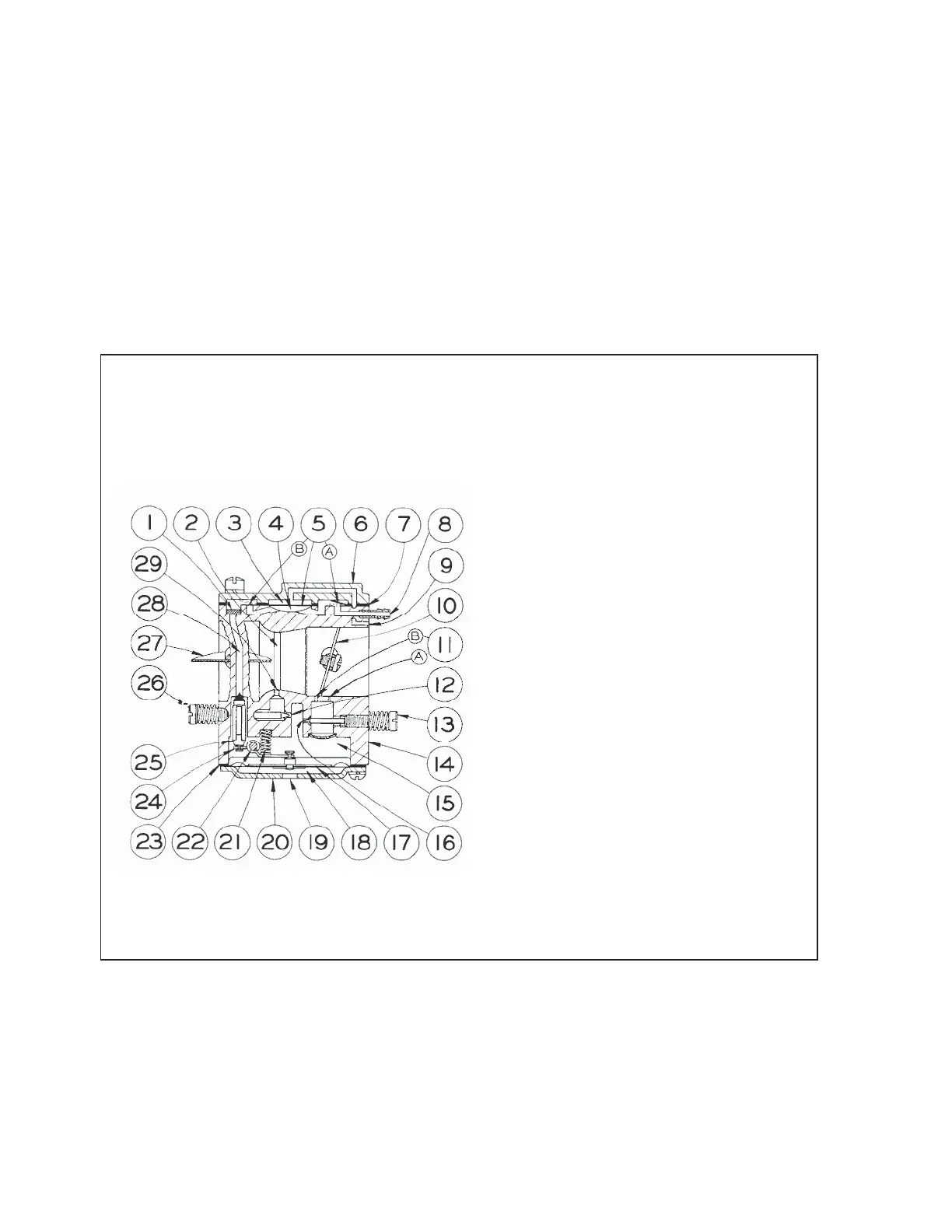

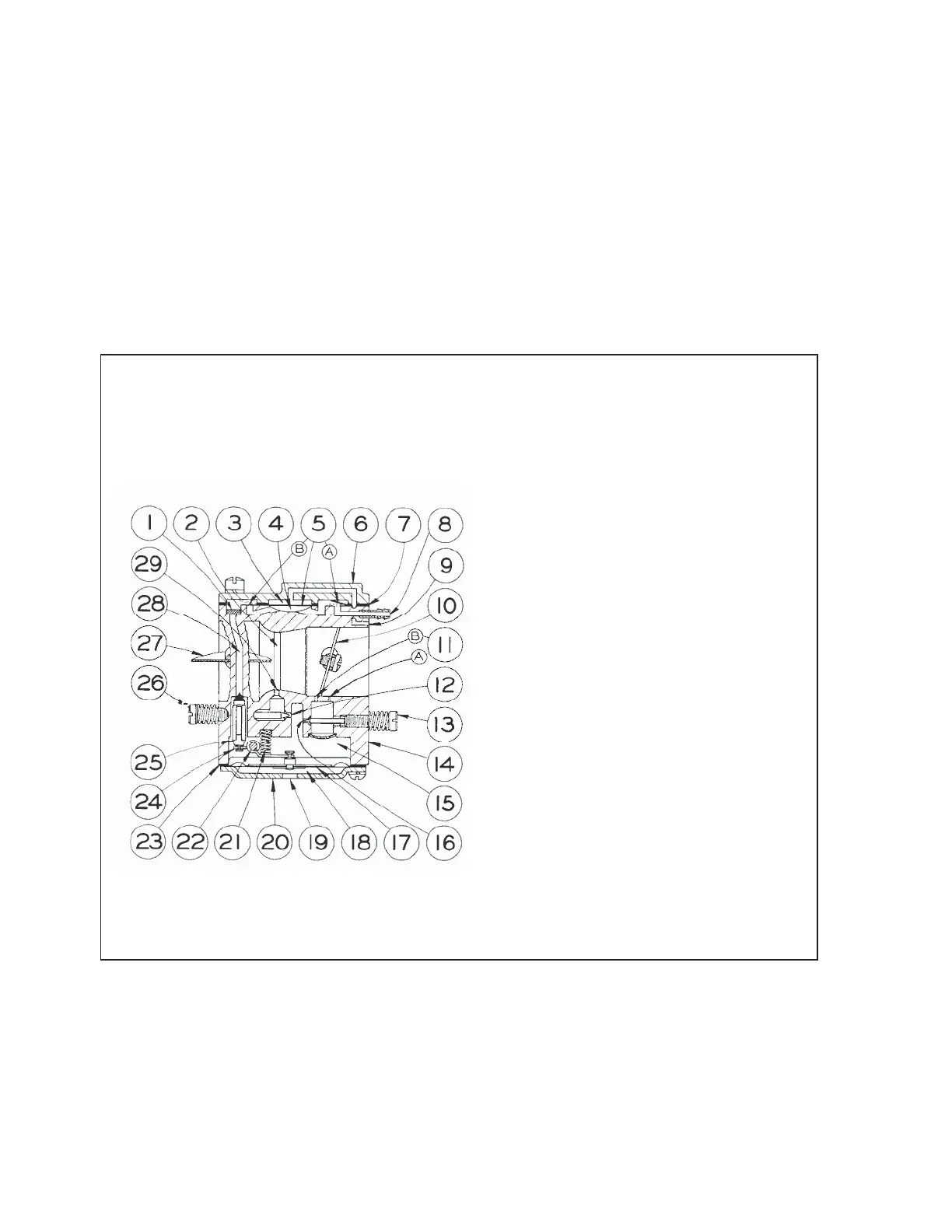

HS SCHEMATIC

1. Filtering Screen

2. Venturi

3. Pulse Chamber

4. Fuel Chamber

5. Fuel Pump Diaphragm

5A. Diaphragm Pump Inlet Valve

5B. Diaphragm Pump Outlet Valve

6. Fuel Pump Body

7. Fuel Pump Gasket

8. Fuel Inlet

9. Impulse Channel

10. Throttle Shutter

11A Primary Idle Discharge Port

11B Secondary Idle Discharge Port

12. High Speed Mix. Screw Orifice

13. Idle Mixture Screw

14. Body

15. Metering Chamber

16. Idle Mixture Screw Orifice

17. Diaphragm

18. Atmospheric Chamber

19. Atmospheric Vent

20. Diaphragm Cover

21. Inlet Tension spring

22. Fulcrum Pin

23. Diaphragm Gasket

24. Inlet Control Lever

25. Inlet Needle

26. High Speed Mixture Screw

27. Choke Shutter

28. Fuel Inlet Supply Channel

29. Main Nozzle Discharge Port

INTRODUCTION

Loading...

Loading...