7/21

11

* Shipped Dry

FIGURE 10

4. LUBRICATION - The precision - made gears and bearings in our reducers require high-grade lubricants of the proper

viscosity to maintain trouble- free performance. All standard reducers ordered from the factory are lled with ISO

viscosity grade Mobil Glygoyle 460 polyalkalene glycol (PAG) lubricant. If oil needs to be added or changed,

ONLY compatible polyglycol lubricants should be used. Contact the factory for more information.

5. TEMPERATURE - Most Titan Units are supplied with wormgear reducers. These units may run at temperatures

between 100 degrees to 200 degrees F. (Higher temperatures are especially common during start up). There is NO

NEED TO WORRY unless temperatures exceed 200 degrees F.

6. GENERAL MAINTENANCE - Regular inspection to insure the reducer bolts and screws are tight, correct alignment

of shaft and/or coupling, no major oil leaks, no excessive heating and no unusual vibration or noise will

insure maximum life and performance of the reducer.

BEARINGS

1. LUBRICATION - Bearings used on Titan Conveyors are normally pre-lubed for life. If customer requested, re-lube

bearings are provided, the use of a #2 consistency lithium based grease is advised. Greasing Frequency should be

as many times as necessary to maintain a small lm of grease leaking at the seals. This will protect against

foreign materials entering the bearing. The following list is provided to aid you in acquiring the proper grease or

an equivalent.

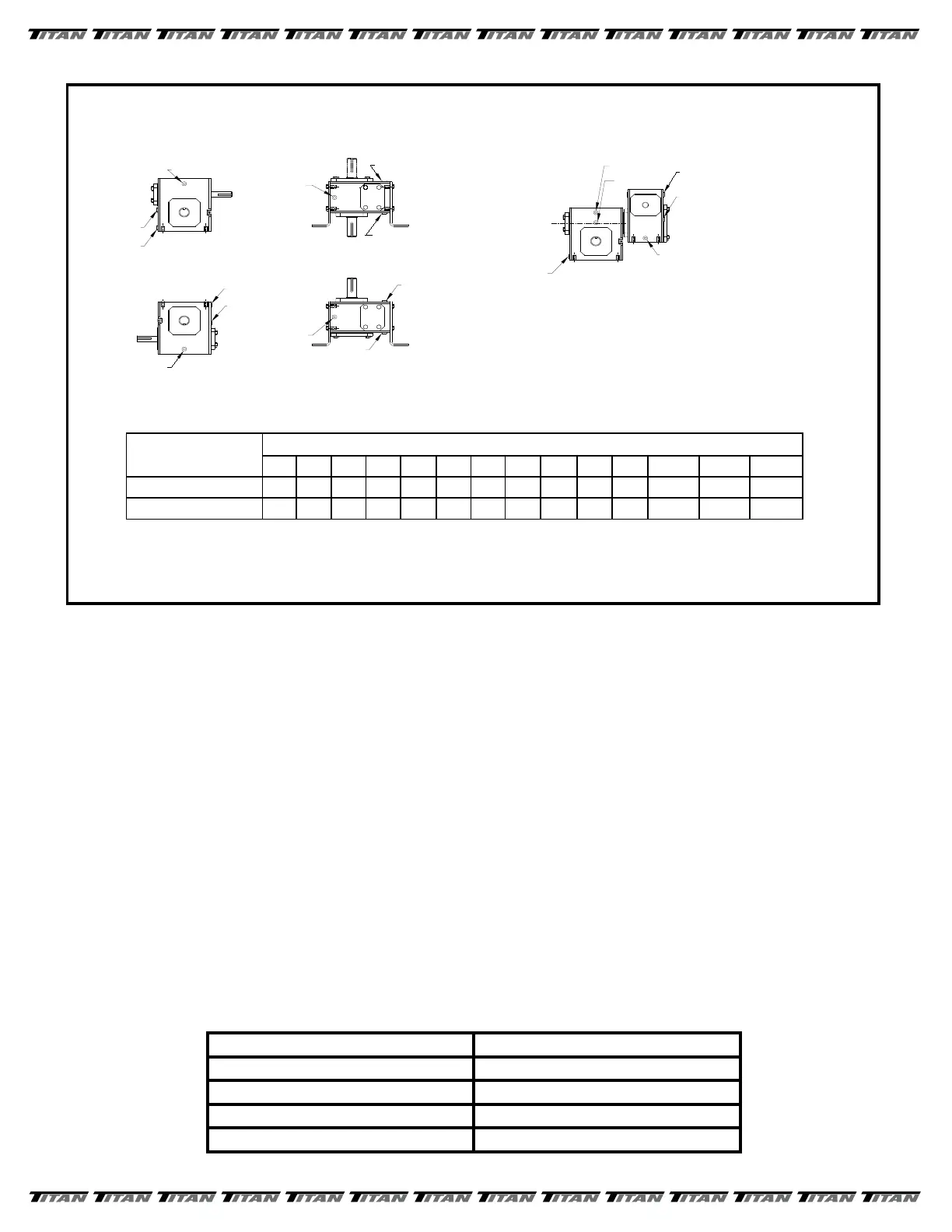

Mounting

Position

UNIT SIZE

813 815 818 821 824 826 830 832 842 852 860 870* 880* 8100*

1 - Worm Over 4 12 12 20 24 40 56 72 112 188 312 35 48 72

2 - Worm Under 8 16 20 28 40 60 84 108 152 304 328 32-3/4 51-1/4 80

Oil Capacities (ounces) - Standard Units

16 0z. = 1 pint

2 pints = 1 quart

4 quarts = 1 gallon

1 gallon = 128 oz. = 231 Cu. in.

DRAIN

LEVEL

VENT

WORM OVER

VENT

LEVEL

DRAIN

VERTICAL OUTPUT

VENT

LEVEL

DRAIN

WORM UNDER

VENT

LEVEL

DRAIN

VERTICAL INPUT

LEVEL*

VENT

DRAIN

VENT

LEVEL

DRAIN

DOUBLE REDUCTION WORM-WORM

(All primary units have

their own oil level)

* Size 842-860 (far side plug)

Note: High oil level applies to all size 842 & larger

secondary & tertiary units regardless of primary

unit type.

Standard Gear Reducer Mounting Positions

& Vent Plug, Level and Drain Locations

NORMAL DUTY HEAVY DUTY

Texaco - Multifak #2 Sun - Prestige 742EP

Mobile - Mobilux #2 Exxon - Lidok #2EP

Amoco - Lithium MP Arco - Litholene HEP2

Shell - Alvania #2 Shell - Alvania #2EP

Loading...

Loading...