Injection Molding Machine Chapter 5

V3.0

5-11

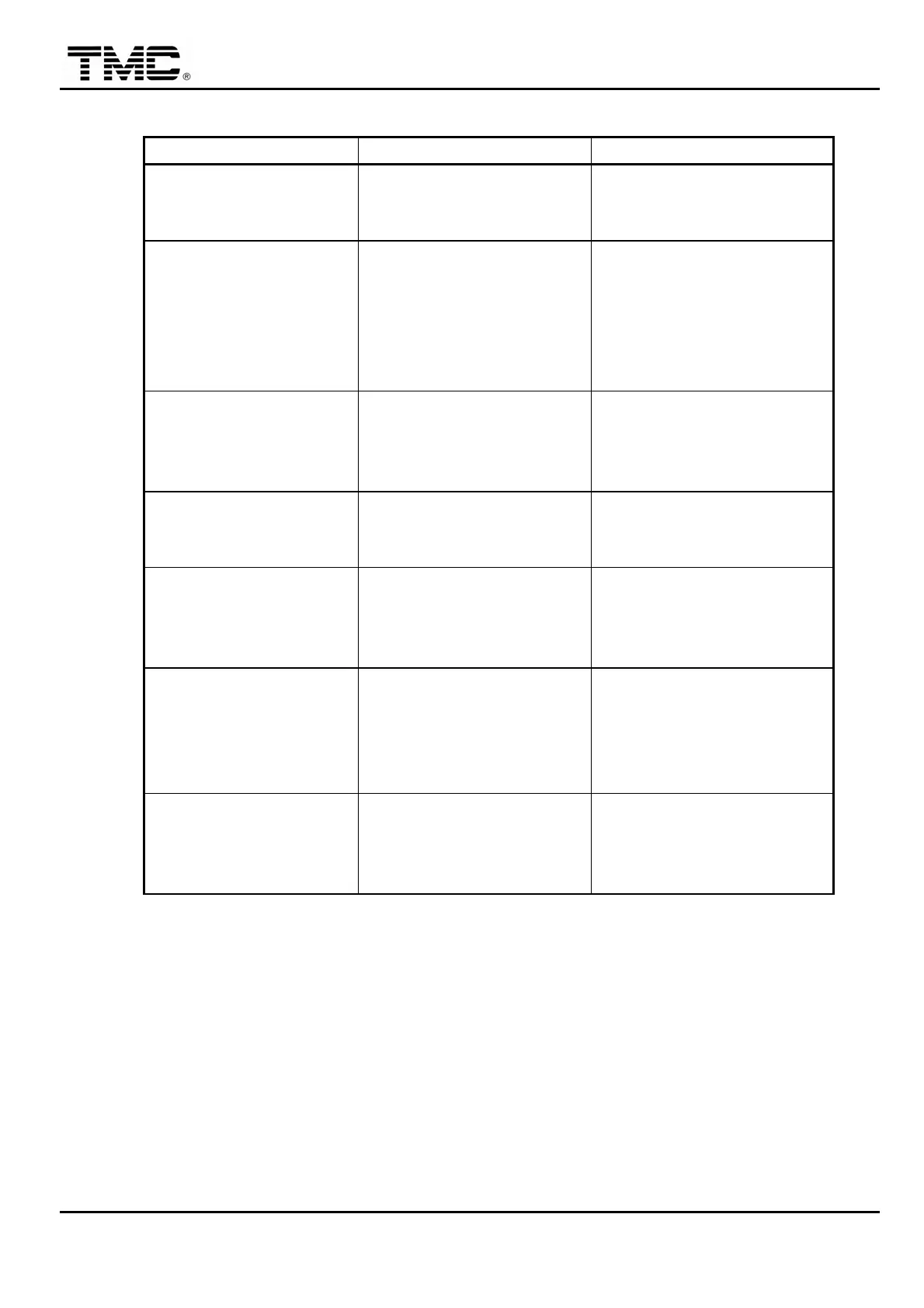

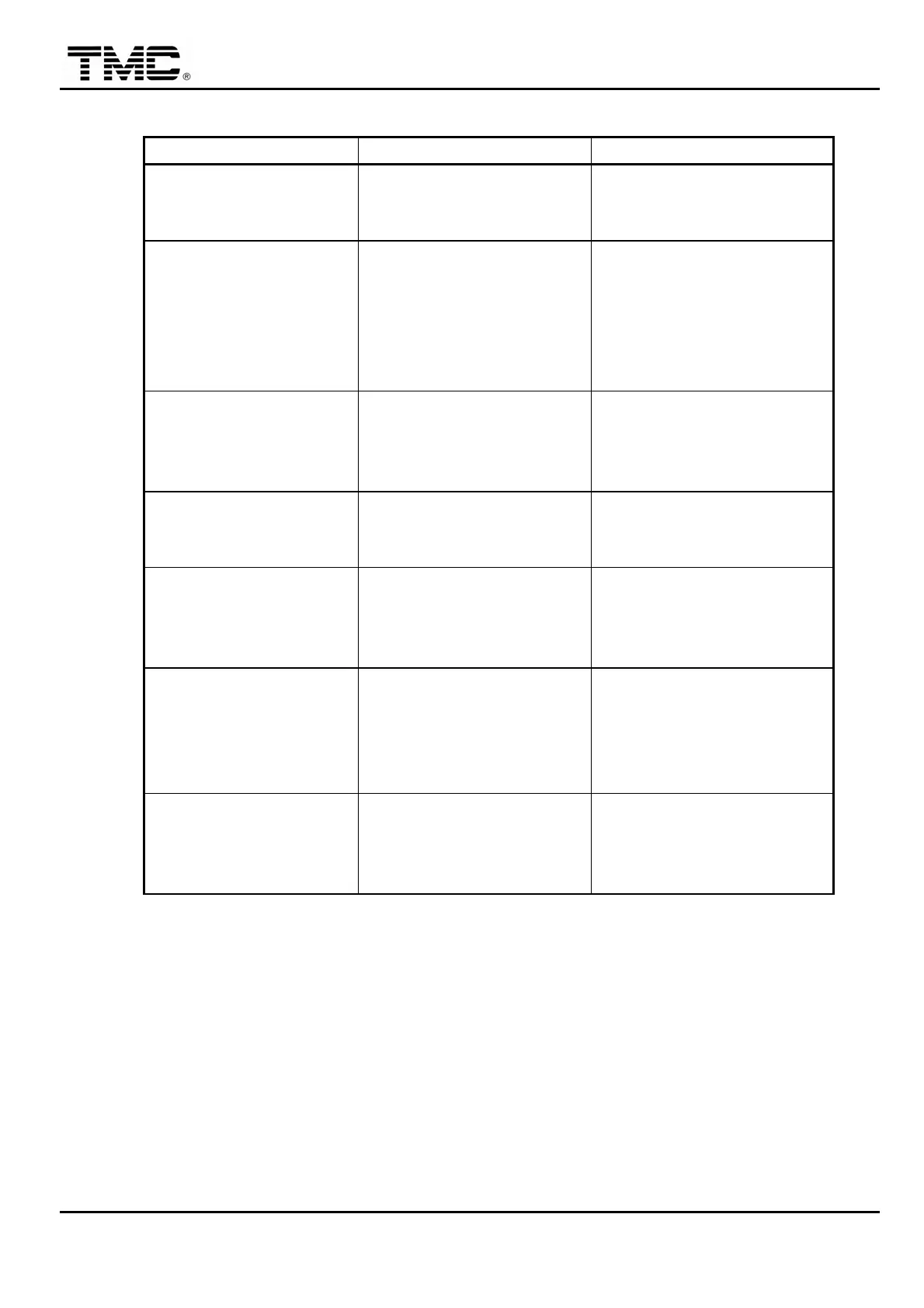

Content of Alarm Cause of Alarm Release of Alarm

28. Total parts count over

Please check part shot

count & setting

S/A: Product counting

exceeded

1. Open safety gate

2. Reset product counter

29. Control panel temp.

too HI./LOW

Please check control

panel. Temperature &

cooling it down less 50

℃

M/S/A: temperature inside

control box exceeds

65 degree or in

negative

temperature

1. Open safety gate

2. Improve temperature

condition inside control box

3. TP board +20, C wire

breaking

30. Mould dose not open

end (not end)

Please open the mould

at open end position

M: clamp open/close position

is not at end position

before barrel cleaning

1. Open safety door

2. Clamp must be open before

cleaning barrel

31. Purge cover be open

Please check purge

cover & input no. 210

M/S/A: I/O 210 OFF

1. Open safety gate

2. Close nozzle cover

3. Check limit switch

32. Parts not pass

(confirmation)

Please check parts &

input no.122

S/A: When T/C 326 starts

time counting I/O 122

OFF

1. Open safety gate

2. Check product pick-out

device

33. Heater temperature

ready

Please open the door

and close to reset

alarm

M: Temperature reaches to

set value and T/C 42-

cold material start

protection time

completed.

1. Open safety gate

34. Function not selected

Please check this

function is it enable!

M: function selection not

performed before

operation of manual

button

1. Open safety gate

2. Select this function

Loading...

Loading...