Injection Molding Machine Chapter 5

V3.0

5-13

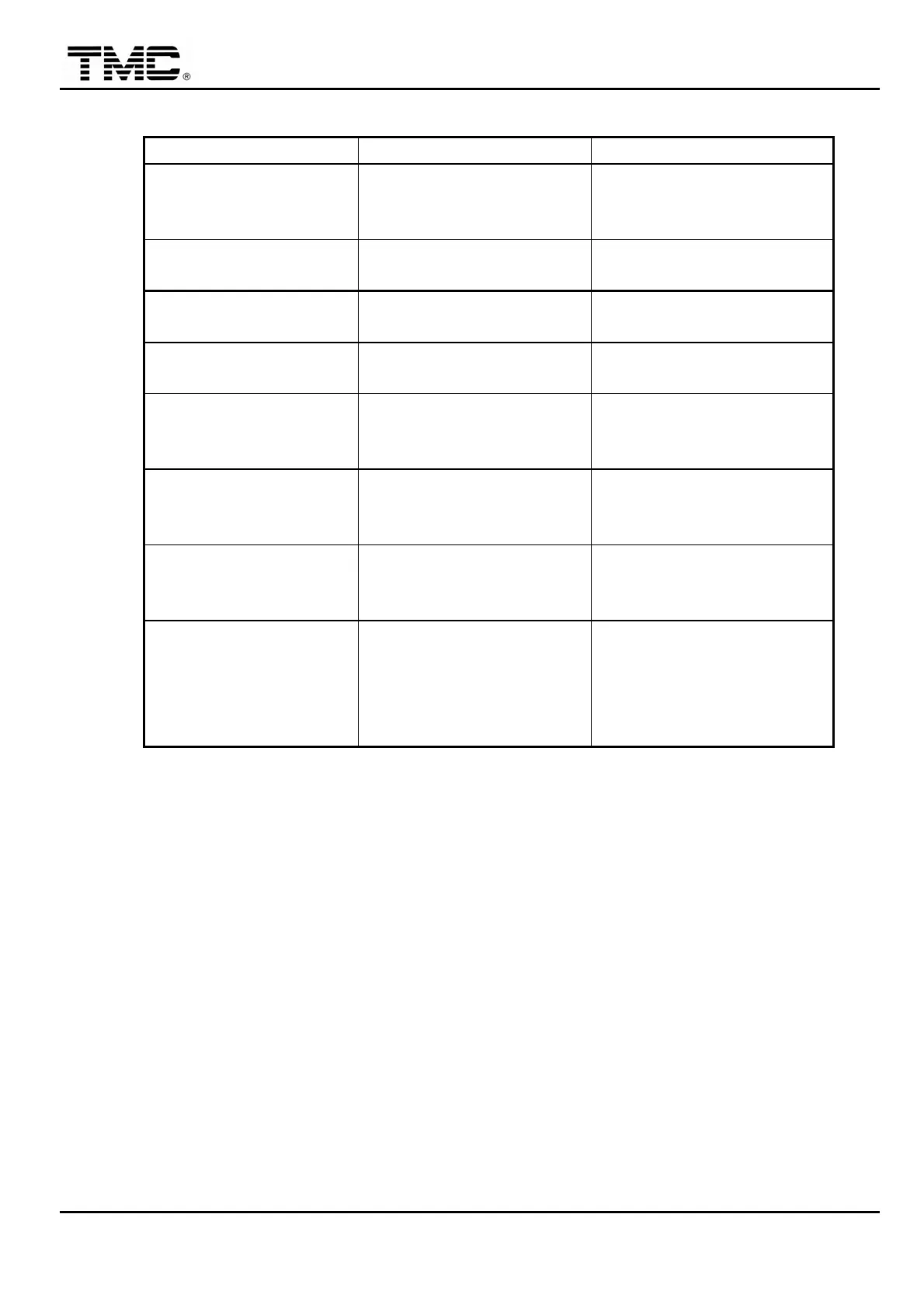

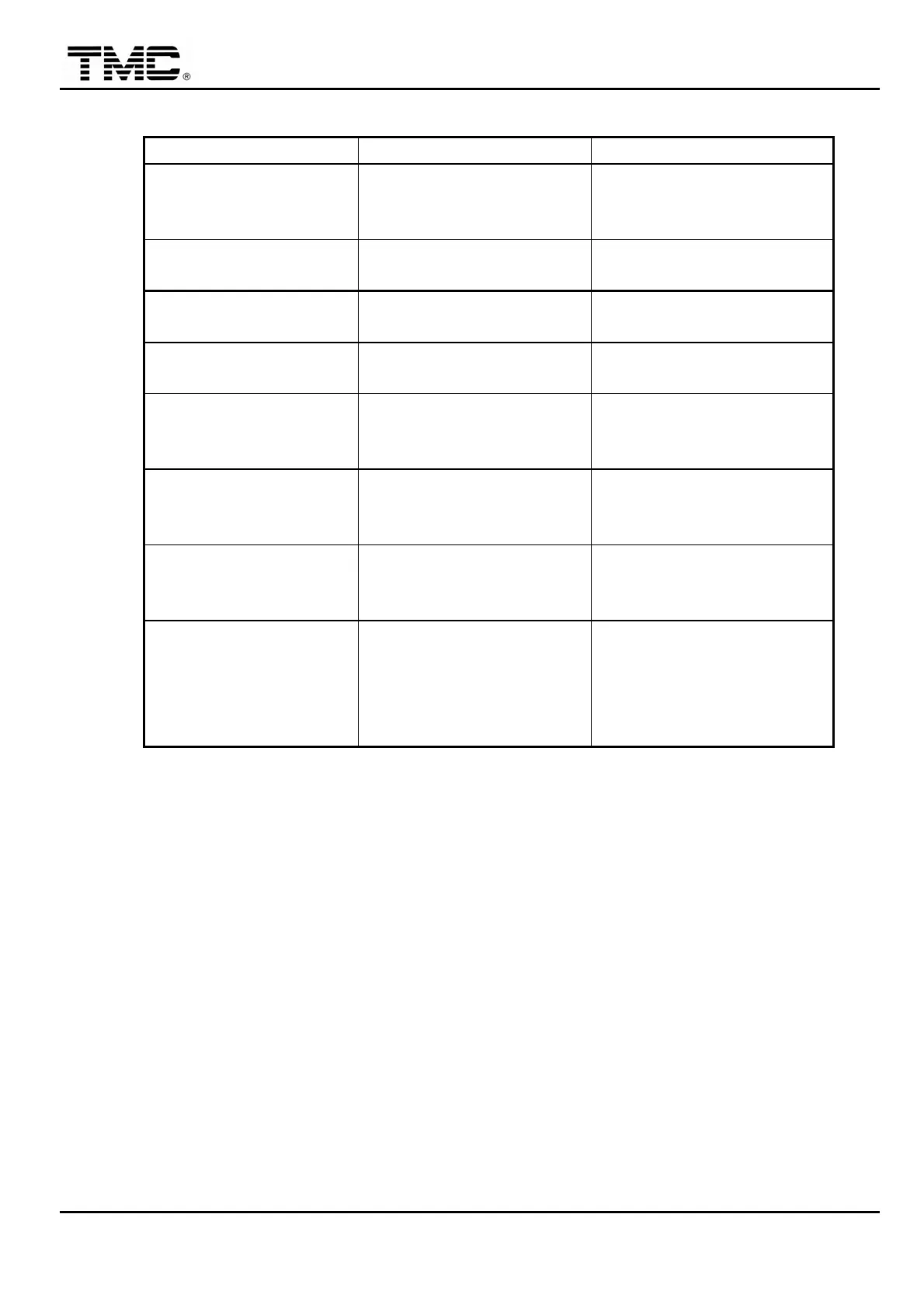

Content of Alarm Cause of Alarm Release of Alarm

73. Under mold adjust

mode

S/A: Mold adjusting function

not off

1. Open safety gate

2. Turn off mold adjusting

function

76. Safety door #3 rear be

open I/O 110

S/A: No.3 safety gate not

closed

1. Open safety gate

2. Close No.3 safety gate

77. Safety door #4 rear be

open I/O 201

S/A: No.4 safety gate not

closed

1. Open safety door

2. Close No.4 safety door

78. Safety door #5 rear be

open I/O 205

S/A: No.5 safety gate not

closed

1. Open safety gate

2. Close No.5 safety gate

89. Hyd. Safety valve

monitor device is

opened

M/S/A: After operation door

is closed

I/O 109 not ON

1. Open safety gate

2. Check safety valve monitor

device

92. Core in not completed

before clamp close

M: Core-in operation not

completed

1. Open safety gate

2. Perform manual core in

3. Check corepull device

93. Core out not

completed before

clamp open

M: core –out operation not

completed.

1. Open safety gate

2. Perform manual core out

3. Check corepull device

97. Machine not

maintenance

M/S/A: maintenance cycle

reached.

1. Press alarm buzzer button

2. Switch to manual mode

3. Do maintenance procedure

4. Press F8 on maintenance log

screen

Loading...

Loading...