Injection Molding Machine Chapter 4

4-12A

V3.0

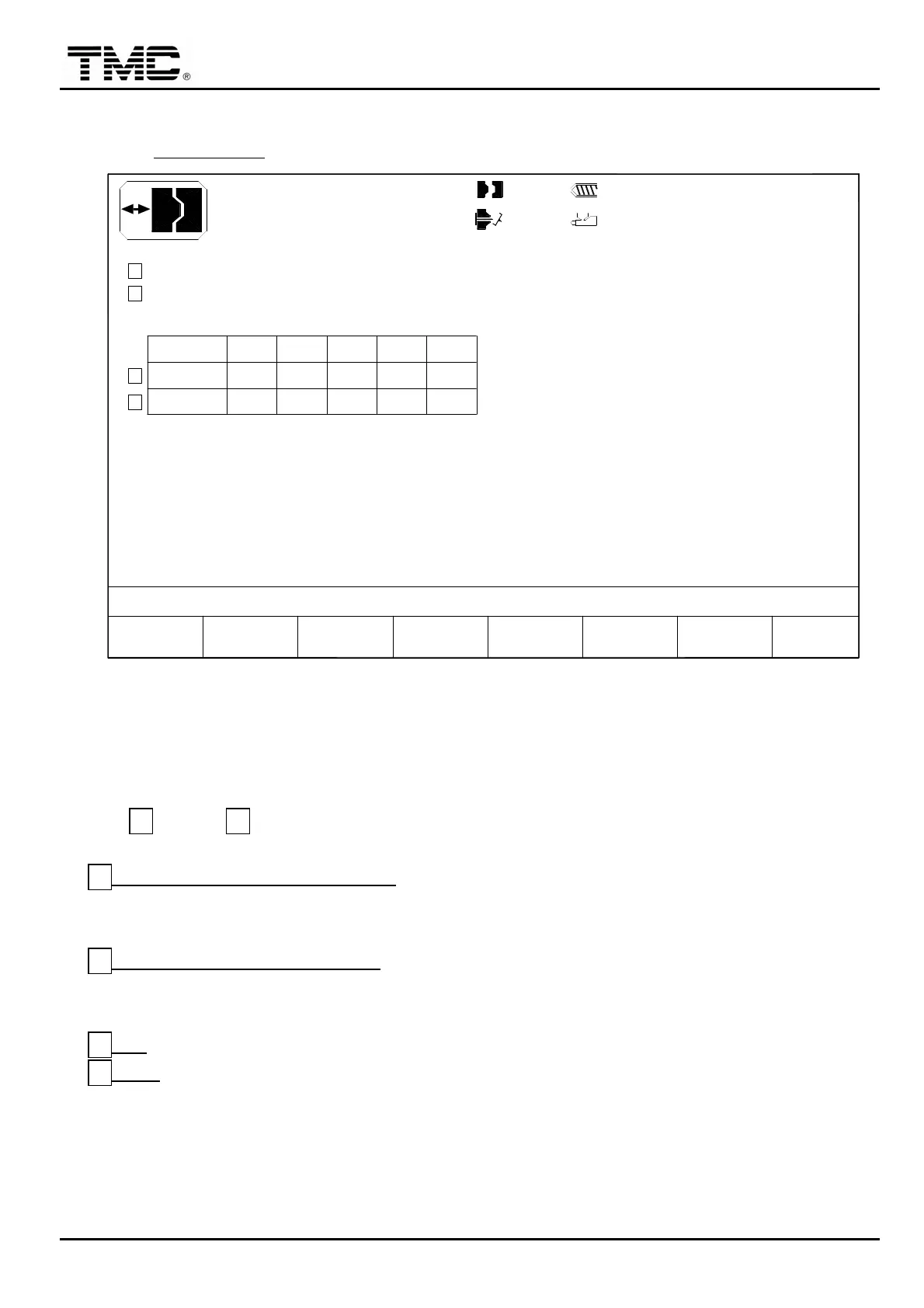

2.4.1Mold Compression (for H2-SE model)

On 於 MOLD ADJ. screen, press F2 to enter this screen.

V1: 0/ 0 0/ 0V2:

0/ 0P1: 0/ 0 P2:100.0mm

50.0mm110.0mm

10.0mm

STATUS

M:

10D05M10Y

10h25m10s

20°C1W

INJ. END MOLD COMPRESS

OFF

F2F1 F3 F4 F5 F6 F7 F8

MENU

11

A

V %

PBar

123451

50 50 50 50 50

35 50 75 100 140

C

D

B

< 16.5>

CLAMPING STATUS : 0 TON

PRESENT MOLD PRESSURE : 0 Bar

MOLD

COMPRESS DIE HEIGHT

AUTO

TONNAGE

AUTO

LOG

CHANGE

LOG

ALARM

SUPPORT

MOLD

COMPRESS START INJ.PT.

畫面 3-8A

This sequences can reduce injection pressure during molding process, therefore

eliminate product warpage and increase finished parts reproducibility,mold

structures has to be suitable for compression sequences.

Set A OFF,B position to 0.0 when it is not used.

A INJ. END MOLD COMPRESS

: when set ON, compression sequences start at

transfer position, mold lock pressure increases according to setup point,hence

clamping force also increases to compress molded parts.

B COMPRESS START INJ.PT.: compression sequences start when injection

position reached this set position,mold lock pressure increases according to setup

point,hence clamping force also increases to compress molded parts.

C V%:speed command of mold closed。

D PBar:pressure command for mold closed,it must be bigger one after another.

Compression sequences run according to speed and pressure commands,when actual lock-up pressure

reached setup pressure,sequence shifts to next step.

Loading...

Loading...