Injection Molding Machine Chapter 4

V3.0

4-13

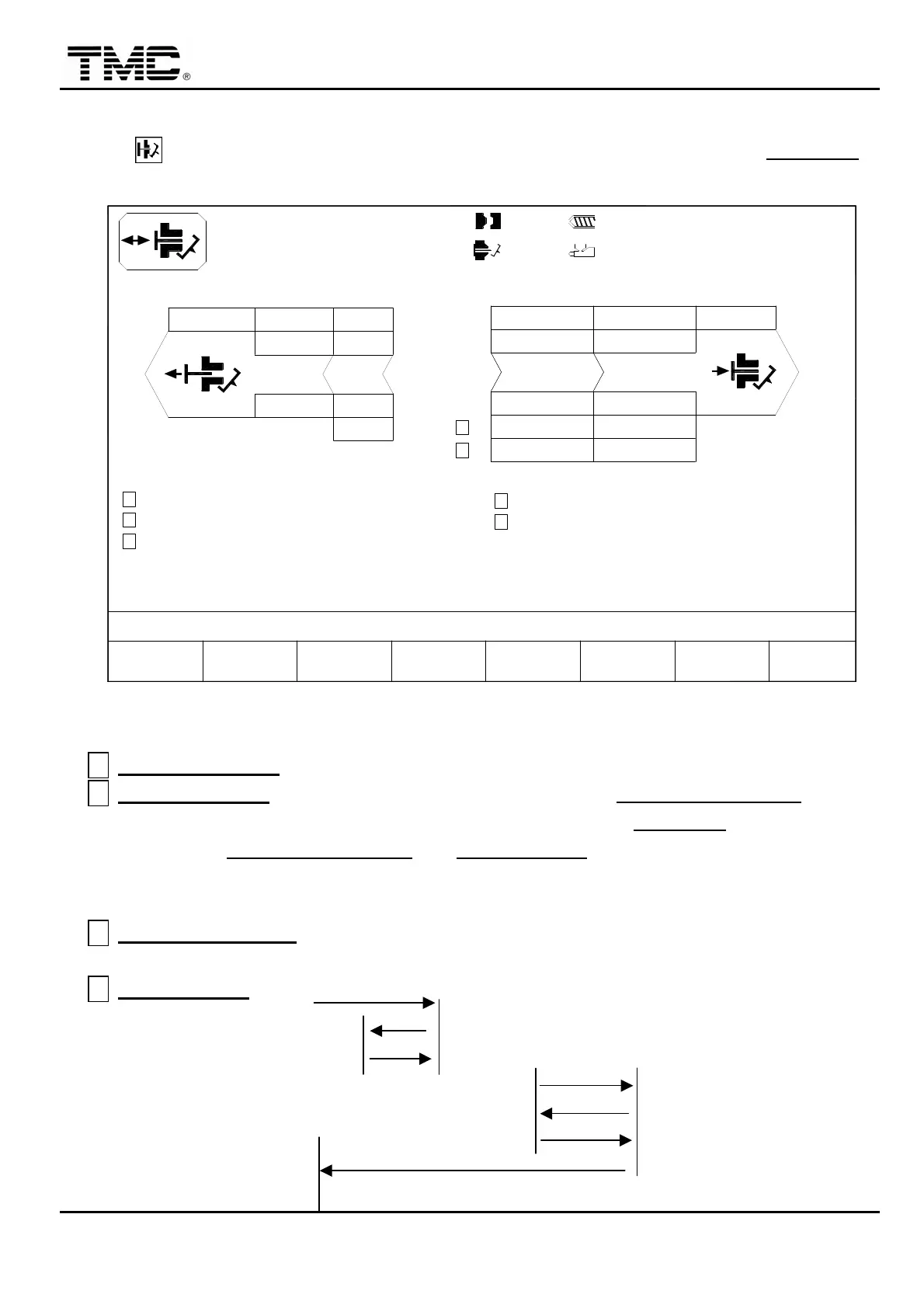

2.5 Ejector setting

Press HOT key or use the direction key in the main menu to move cursor to EJECTION

then press ENTER to display ejector screen.

FWD.1 FWD.2 FWD. END

PT mm

P bar

V %

V1: 0/ 0 0/ 0V2:

0/ 0P1: 0/ 0 P2:100.0mm

100.0mm

110.0mm

0.2mm

ACTION STATUS

M:

14D05M10Y

10h25m10s

20°C5W

EJECT FUNCTION

EJECT SHAKING

ON

OFF

30

0.5

10

40

25.0

90 100

80.0

140

PARAMETER

EJECT.F2F1 F3 F4 F5 F6 F7 F8

MOLD ADJ. CORE LOG SUPPORTMENU

02

I/O

RET.END

RET.2

OFF

PRODUCT SENSOR

EJECT RET. MID. PT.

< 60.0>

CHANGE MOLD EXTERN PROD.

MANAG.

C

B

A

F

30

RET.1

50

10.0

0.2

DELAY

COUNT

0.2 0.3

43

ROBOT CYCLE TIME

G

< 60.0>

D

E

Screen 4-8

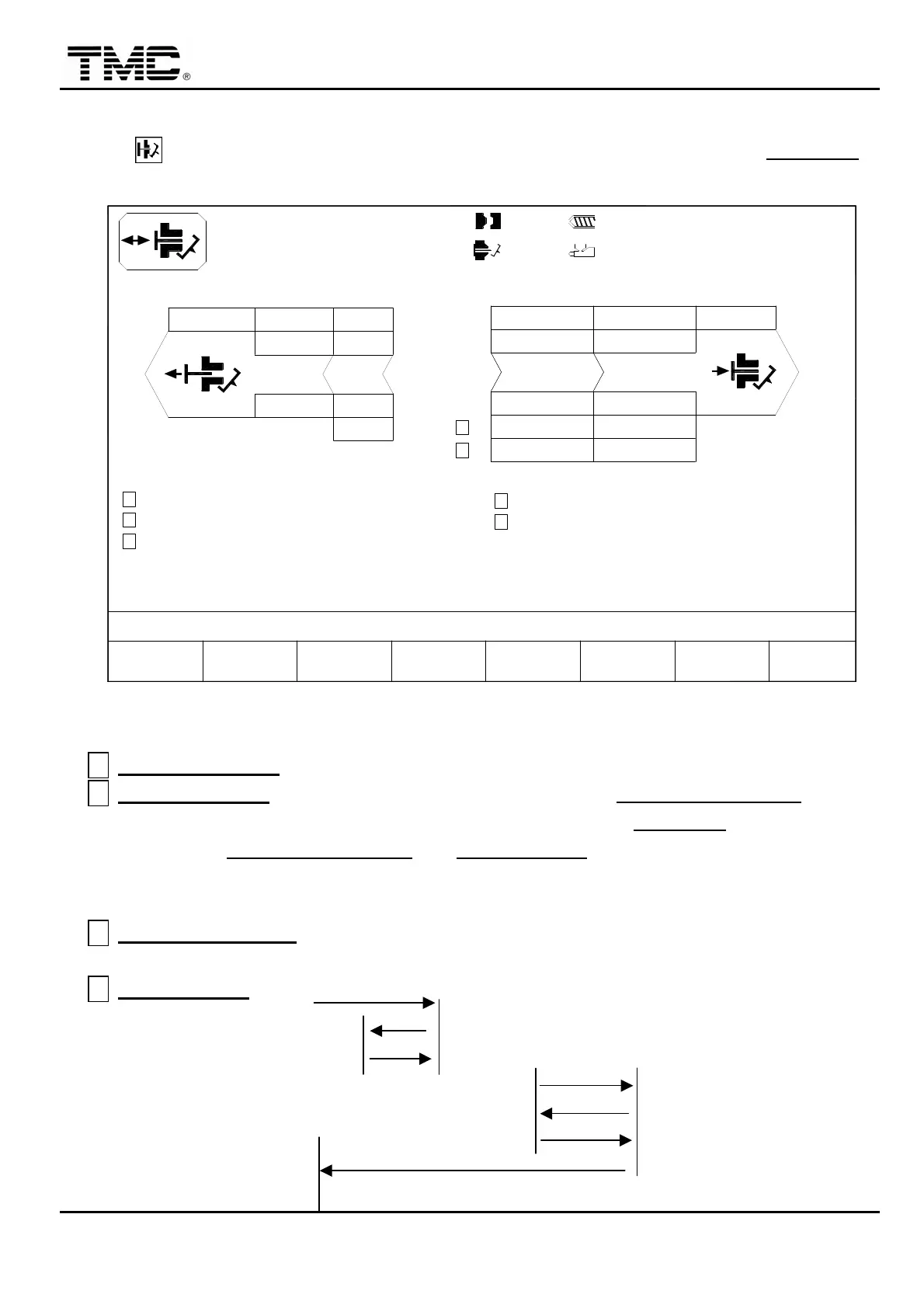

A

EJECT FUNCTION

:

Set on to run ejector process.

B

EJECT SHAKING

:

To run ejector shaking sequences

,

set EJECT RET. MID. PT.

a little

smaller than FWD END position

,

ejector will move forward to FWD. END and then move

backward to EJECT RET. MID. PT.

until EJECT COUNT is reached. This process will

make ejector move forward and backward quickly to shake parts down.(No need to set

the function on)

C

PRODUCT SENSOR

:

Photo sensing device is used to confirm dropped parts. It is an

OPTIONAL DEVICE.

D

EJECT COUNT

: FWD.1 1

2 FWD.1

RET.1 3 PT.

1

EJECT RET. 2

MID. PT 3

4

RET. END PT.

BILL 2

1

2

Loading...

Loading...