Injection Molding Machine Chapter 4

V3.0

4-17

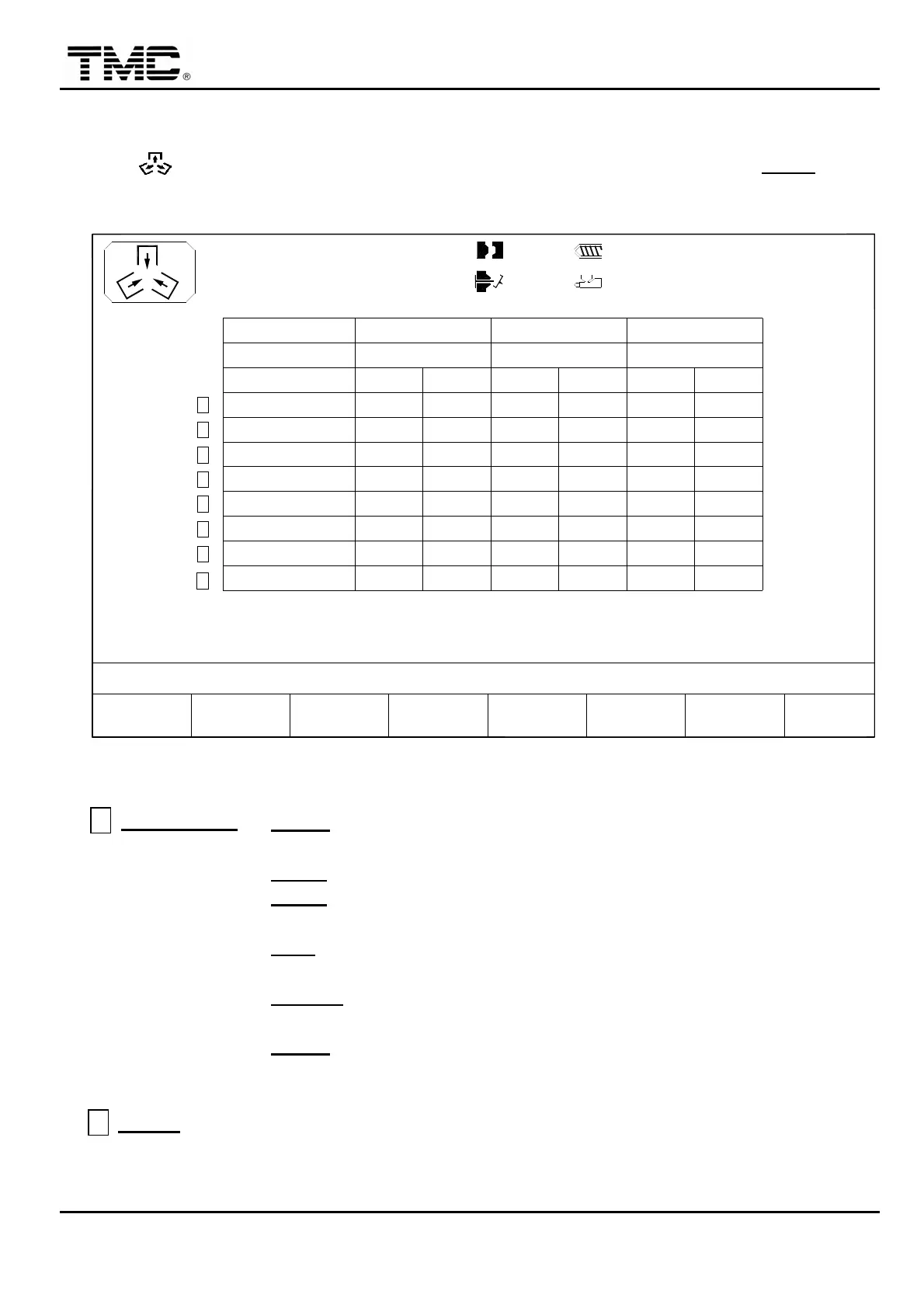

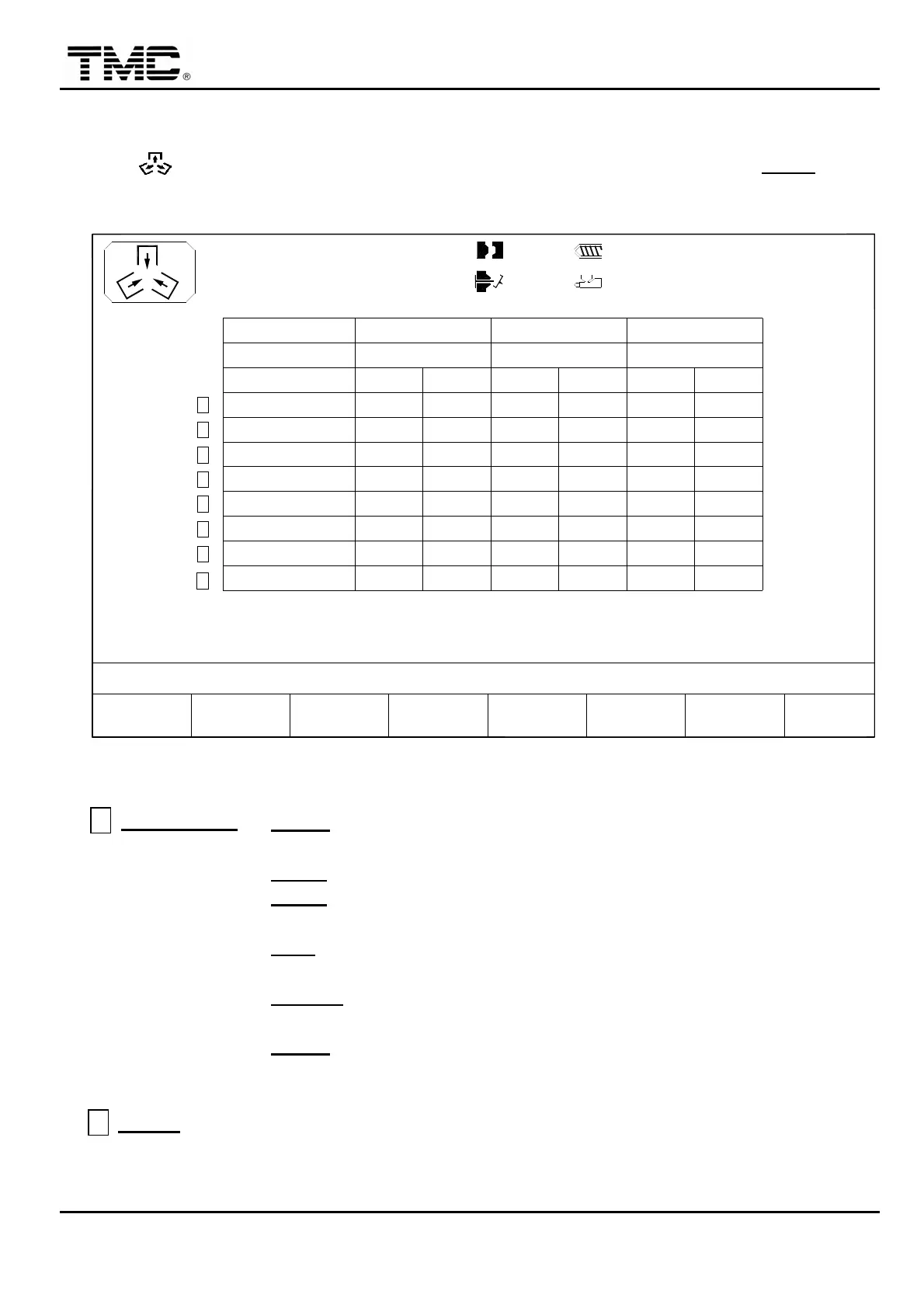

2.7 Corepull setting

Press hot key or use the direction key in the main page to move the cursor to CORE

,

press ENTER to display core screen.

PT mm

P bar

10h25m10s

20°C

PARAMETER

CORE MODE

DELAY T.

COUNT

03D05M07Y

COREF2F1

MENU

01

D

F

H

G

I/O

E

TIME

C

B

V %

A

3W

MOLD

SUPPORT

F3 F4 INJ.

PROFILE

F5 F6CHANGE

LOG

F7 F8EXTERN

I/O

100.0mm

100.0mm

331

100

000.0

100

140

000.0

250.0

000.0

000.0

250.0

OUT

140 140

000.0

000.0

100

131 132

100

100

250.0

100

IN

140 140

000.0

133

100

000.0

000.0

134

100

000.0

100

250.0

IN

250.0

100

OUT

CORE 1

ON

1.0mm

CORE 2

OFF

110.0mm

140

000.0

000.0

332

100

250.0

100

IN OUT

0/ 0

0/ 0 0/ 0

CORE 3

OFF

P1: P2:

0/ 0V1: V2:

ACTION STATUS

M:

OPN_E EJ_F CLO_E POSIT. OPN_E CLO_E

Screen 4-10

A

CORE MODE

:

1

OPN-E

:

Clamp open end

→

Core in

→

Clamp close

→

Injection…

→

Clamp open end

→

Core out.

2

POSIT

:

Core in and out at specified clamp position.

3

CLS-E

:

Clamp close to end

→

Core in

→

Injection….

→

Core out

→

Clamp open

4

EJ_F

:

Clamp open end

→

Ejector forward

→

Core out

→

Core in

→

Ejector backward

→

Clamp close

5

EJ_END

:

Clamp open end

→

Ejector forward

→

Ejector backward

→

Core out

→

Core in

→

Clamp close

6

AS_EJ

:

Clamp open end

→

Core out

→

Core in

→

Ejector forward

→

Ejector backward

→

Clamp close

B

PT mm

:

To set the position of clamp open and close position that initiates operation of

core in and core out.

For example

,

set the core in position at 100.0

,

then core starts move in when the position

Loading...

Loading...